Exhaust hood

A technology for exhaust hoods, air, applied in the field of exhaust hoods, which can solve the problems of odor burden and fire hazard, inaccessible fan impeller ventilation channels, unhygienic, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

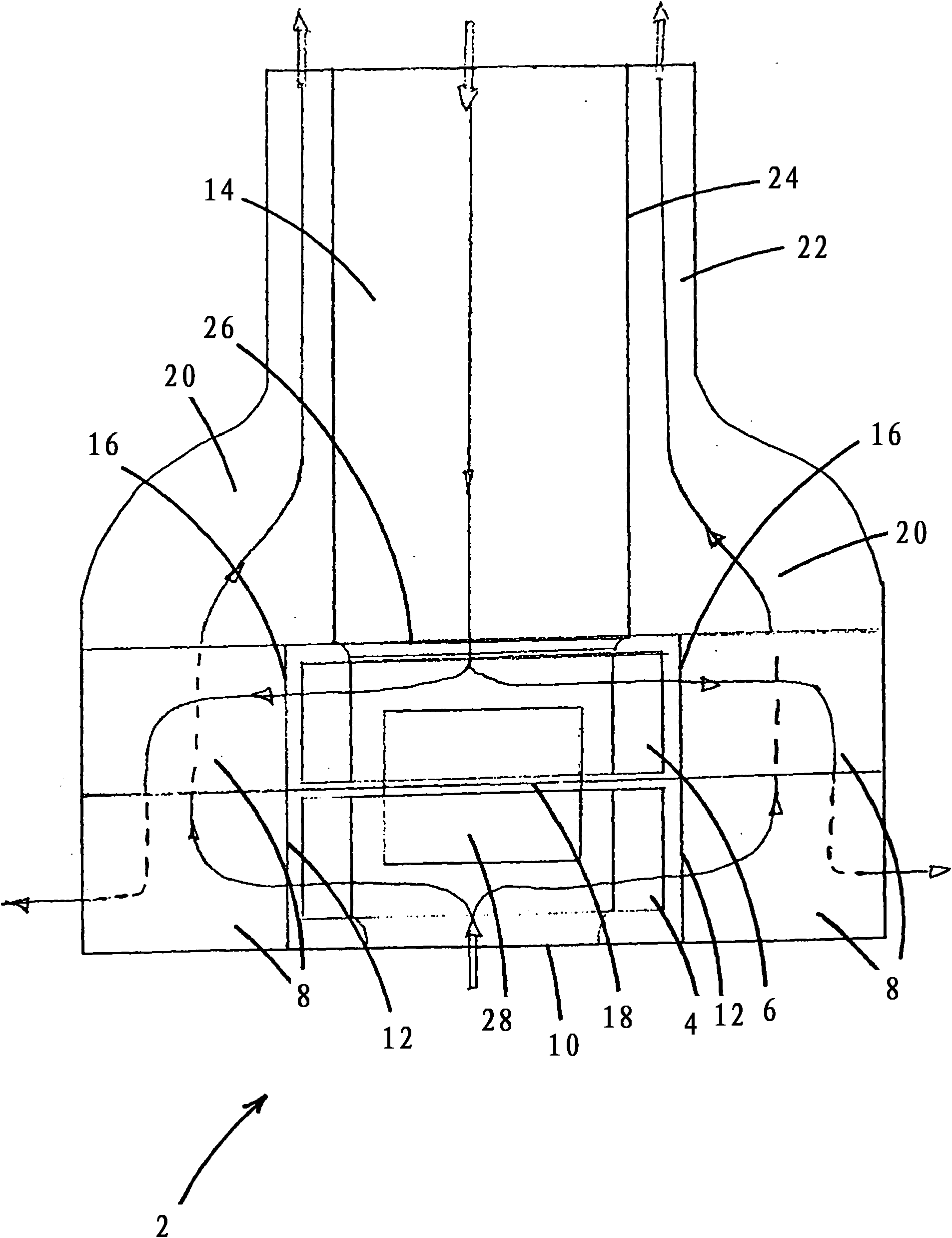

[0027] figure 1A schematic cross-sectional view of the exhaust hood 2 is shown in , in which the first fan wheel 4 and the second fan wheel 6 can be seen. A plurality of guide vanes 8 are arranged around the fan wheels 4 , 6 on the outside. Room air is sucked and accelerated by the first fan wheel 4 through a suction opening 10 and is blown through openings 12 associated with the first fan wheel 4 into the ventilation channels laterally delimited by the guide vanes 8 . In the region of the guide vanes 8 , the room air blown into the ventilation channel (as indicated by the arrows) flows around the second fan wheel 6 .

[0028] Outside air is sucked in by the second fan wheel 6 through the air intake duct 12 and blown through openings 16 associated with the second fan wheel 6 (as also indicated by the arrows) into the ventilation duct laterally delimited by the guide vanes 8 in the way. Since the first fan wheel 4 is separated from the second fan wheel 6 by the partition 18 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com