Arrangement for an internal combustion engine having a plurality of cylinders and exhaust turbocharger, exhaust gas pressure transformer having a mixing tube and a wastegate, and method for operating and configuring such an arrangement

A technology of exhaust gas turbine and exhaust gas pressure, applied in the direction of internal combustion piston engines, mechanical equipment, combustion engines, etc., can solve the problems of knocking tendency, efficiency, and maximum torque reduction of internal combustion engines, and achieve the effect of simple construction and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

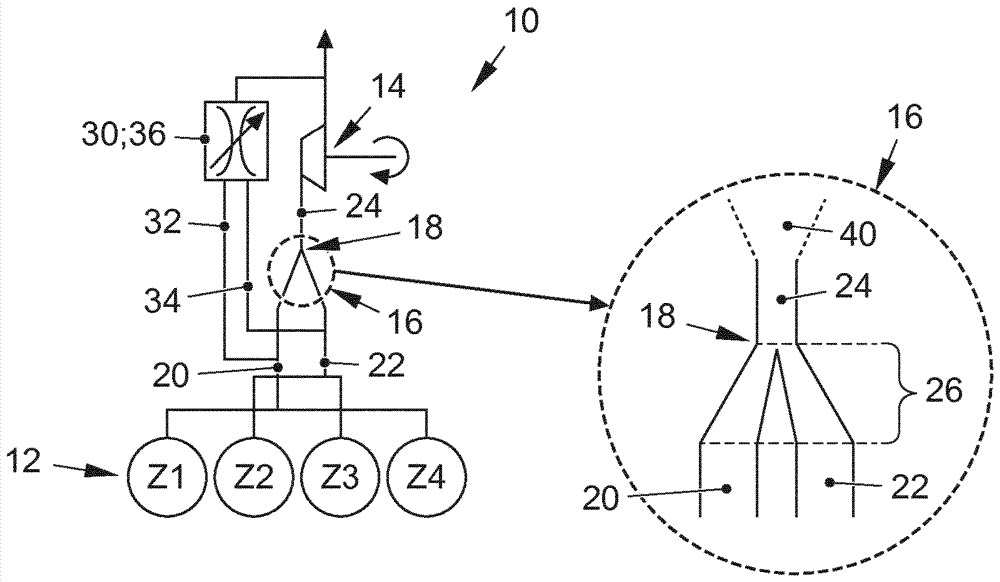

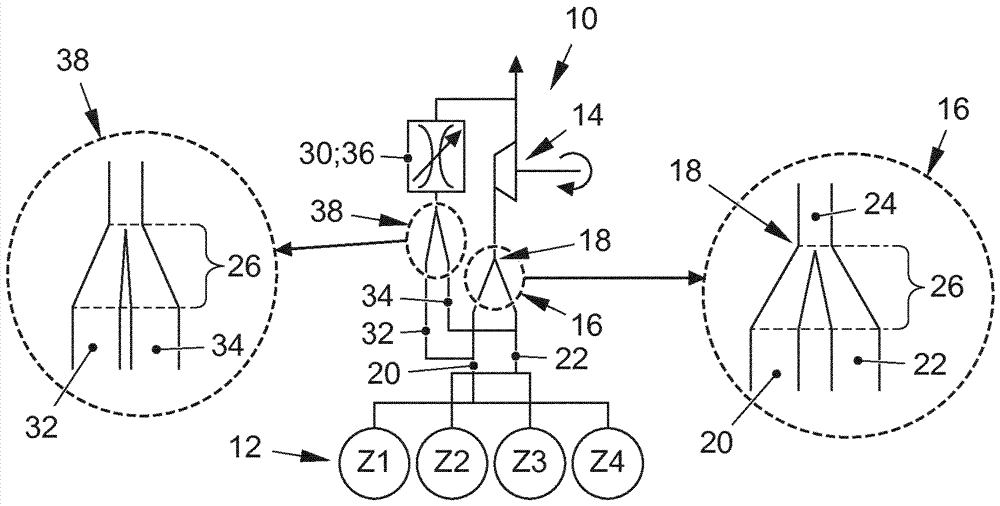

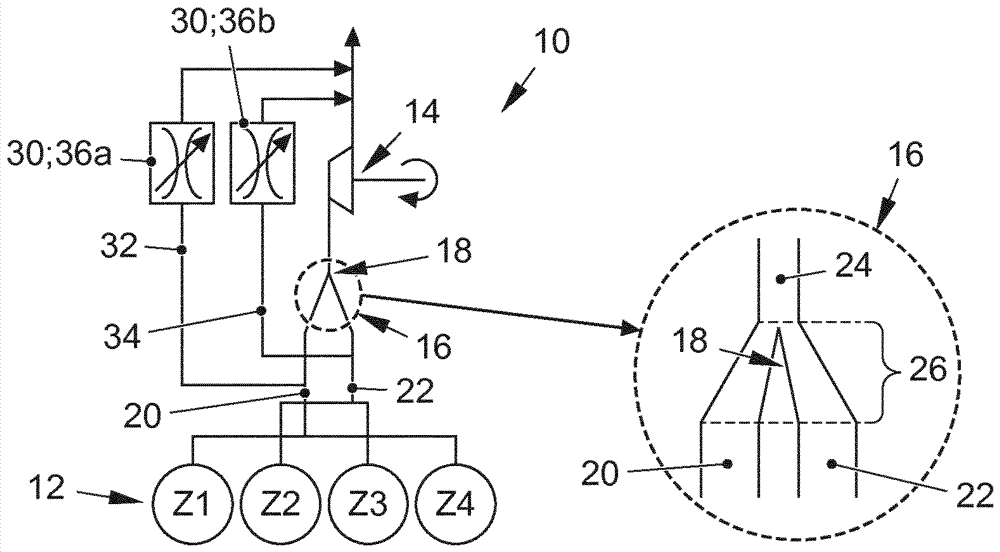

[0029] figure 1 Shown is an assembly 10 known from practice for a schematically illustrated internal combustion engine 12 with four cylinders Z1 , Z2 , Z3 , Z4 , with an exhaust gas turbocharger, wherein in figure 1 Only the turbine 14 arranged downstream of the internal combustion engine 12 is shown in FIG. Furthermore, the assembly 10 includes an exhaust gas pressure converter 16 arranged between the internal combustion engine 12 and the turbine 14 of the turbocharger, the exhaust gas pressure converter 16 being on the right at figure 1 is again shown enlarged next to the assembly 10 shown in .

[0030] The exhaust gas pressure converter 16 comprises a port point 18 at which a first exhaust gas conduction section 20 from the cylinders Z1 and Z4 and a second exhaust gas conduction section 22 from the cylinders Z2 and Z3 are at the are grouped together in a common mixing tube 24 .

[0031] as in figure 1 As can be seen in the enlarged illustration on the right, in the end ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com