Organic-inorganic hybrid monolithic material and application thereof in immobilized enzyme reactor

A technology of monolithic materials and immobilized enzymes, applied in the direction of immobilized enzymes, enzymes, biochemical equipment and methods, etc., to achieve the effects of good regeneration, good permeability, and high enzyme activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

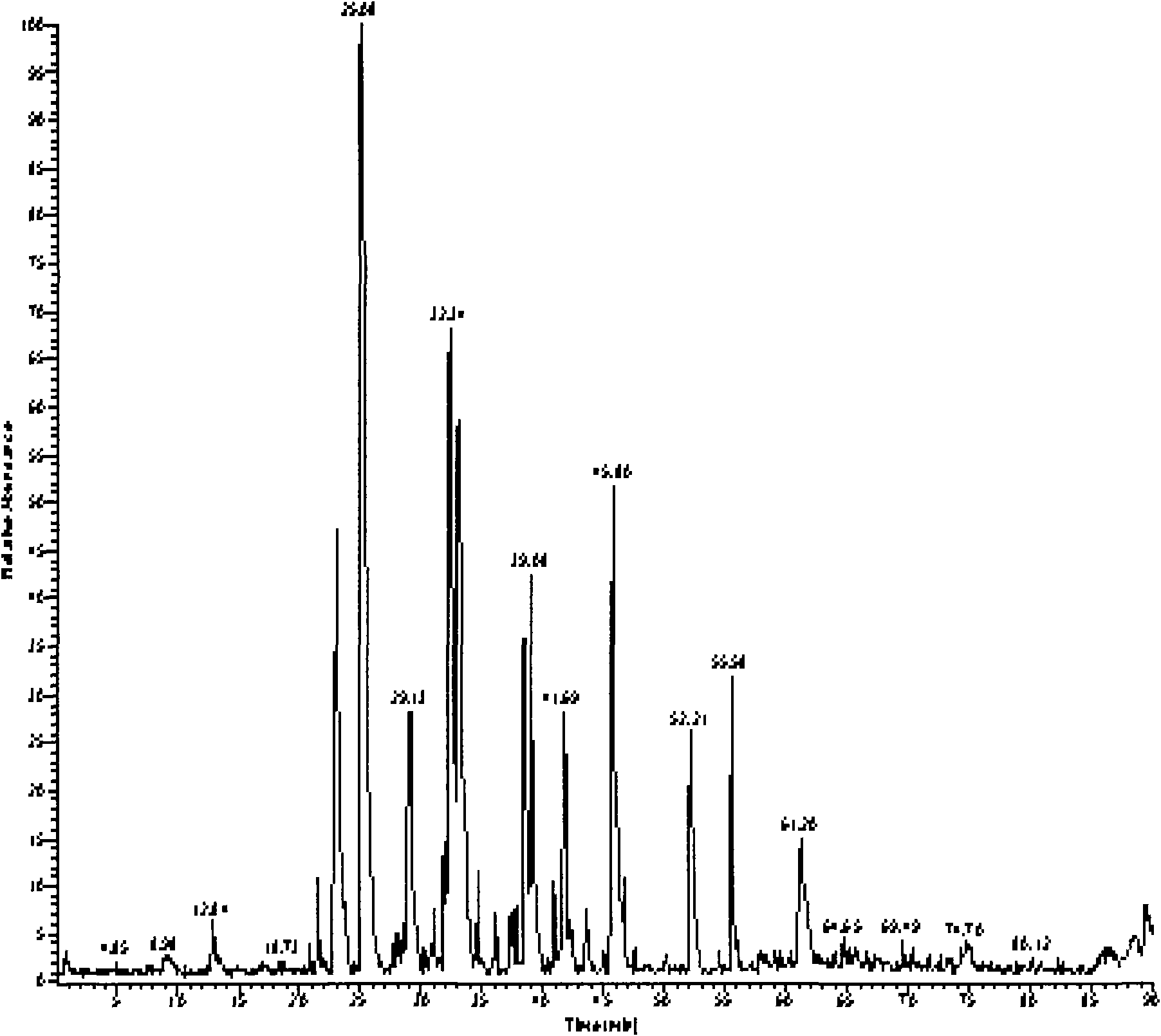

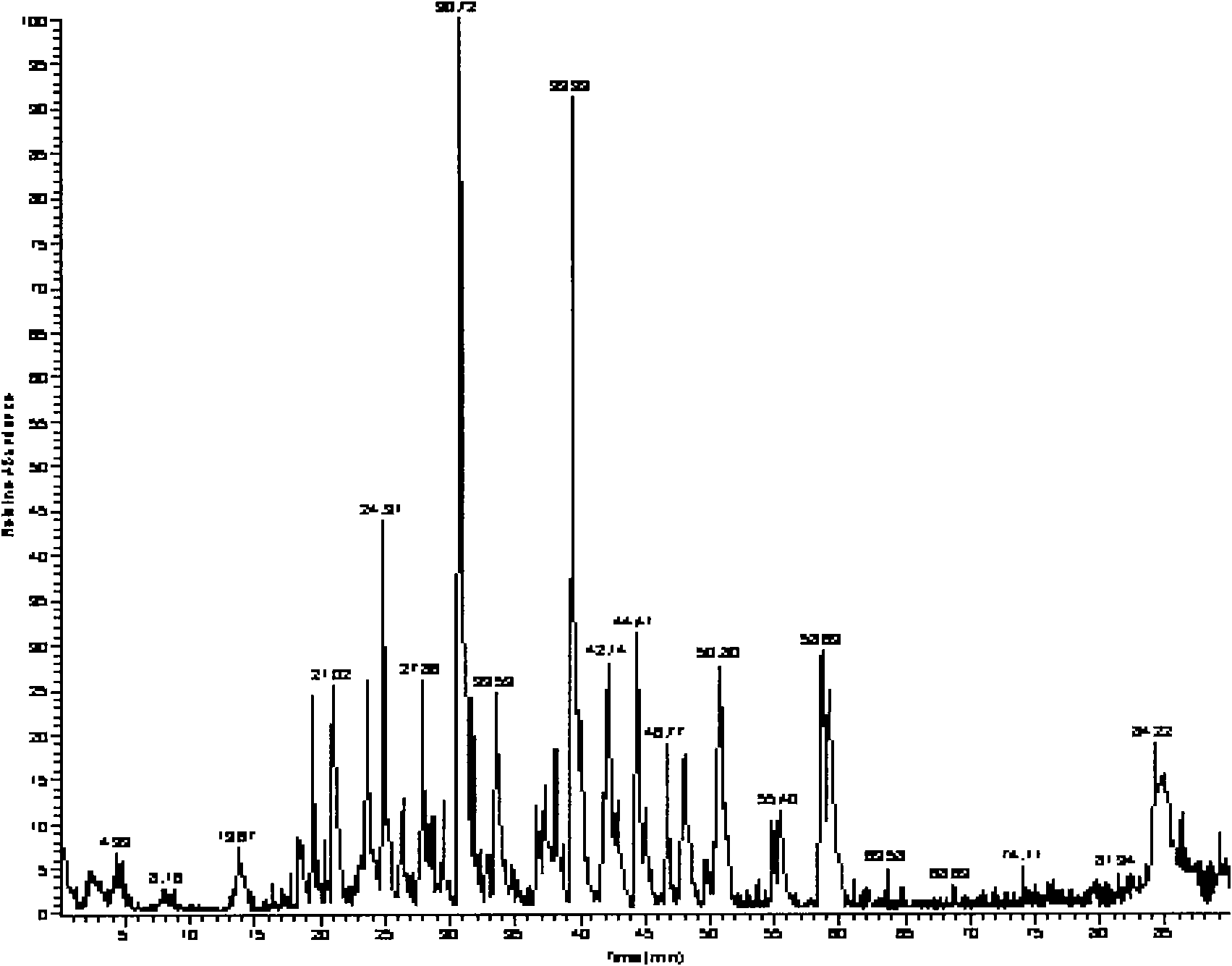

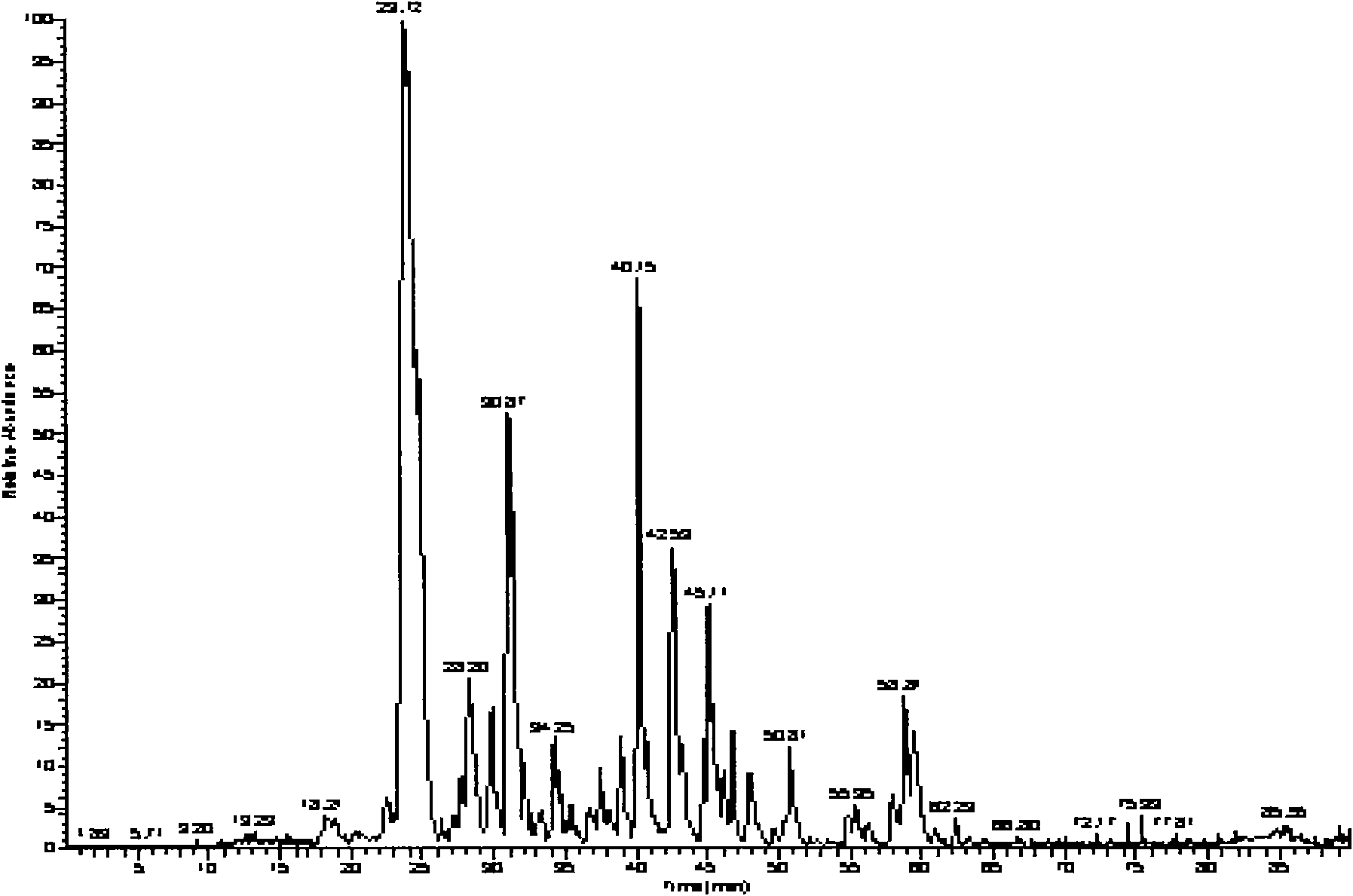

Image

Examples

Embodiment Construction

[0017] A renewable monolithic material-immobilized enzyme reactor was prepared according to the following steps.

[0018] 1. The preparation of the overall material carrier, the specific process is:

[0019] 1) React 2-glycidyloxypropyltrimethoxysilane (GLYMO) with a reagent containing metal ion chelating groups of N, S or O atoms in a water bath to prepare solution A. The specific parameters of the synthesis example are shown in Table 1 below.

[0020] 2) Tetraethoxysilane (TEOS) or tetramethoxysilane (TMOS), methanol or ethanol, hydrochloric acid and H 2 The O mixture was reacted in a water bath to form solution B. The specific parameters of the synthesis example are shown in Table 2 below.

[0021] 3) Mix solution A and solution B, add template molecule cetyltrimethylammonium bromide (CTAB) and catalyst octylamine, prepare a kind of surface with metal ion chelating group through sol-gel method Monolithic material carrier. The specific parameters of the synthesis exampl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com