Synthesis method of core-shell type liquid chromatogram filler

A technology of liquid chromatography and synthesis method, which is applied in the field of synthesis of core-shell liquid chromatography fillers, can solve the problems of time-consuming, incomplete, uneven particle classification, etc., achieve low back pressure, save solvent, and improve separation efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] A kind of synthetic method of core-shell type filler, concrete steps are as follows:

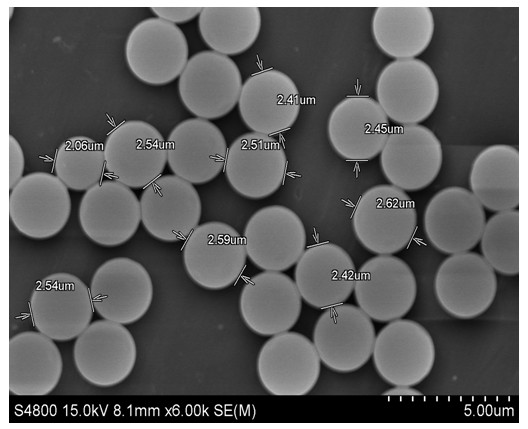

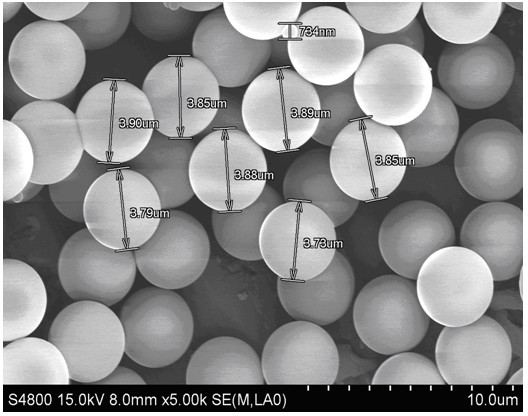

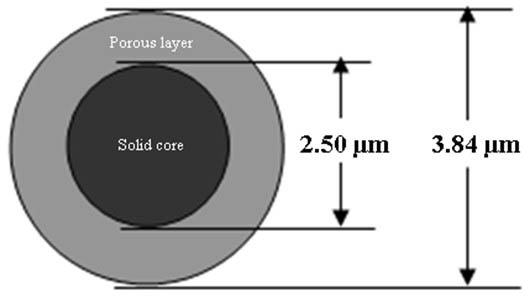

[0033] (1) Mix 82mL of a mixture of silane reagent (tetraethyl orthosilicate) and absolute ethanol at 25°C by magnetic stirring or mechanical stirring to make it evenly mixed and fully reacted to form a 2.45-2.59 μm Specifications of high-purity non-porous spherical silica gel, washed with alcohol and water for many times to remove the catalyst and unreacted reagents on the surface, and then vacuum-dried to serve as the core part of the core-shell filler, see the transmission electron microscope picture figure 1 .

[0034] (2) After the synthesized solid spheres were calcined at 550°C and treated with a mixture of hydrochloric acid and nitric acid, the surface was coated with a layer of cationic polymer electrolyte polymethacrylic acid.

[0035] (3) Mix and stir the solid spheres and nanoparticles treated in (2), so that the nanoparticles are adsorbed and modified on the surface of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com