Core-shell packing applied to liquid chromatography separation analysis and preparation method thereof

A liquid chromatography, separation and analysis technology, applied in the field of chemical analysis and separation, can solve the problems of small pore size, cumbersome operation, and many preparation steps of core-shell fillers, achieve narrow particle size distribution, reduce dead adsorption, and fast separation speed Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

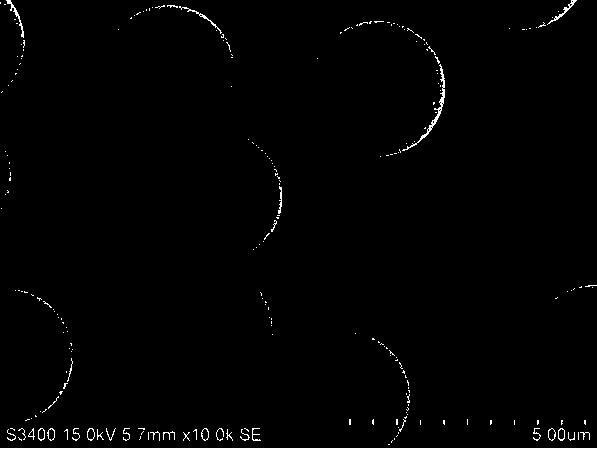

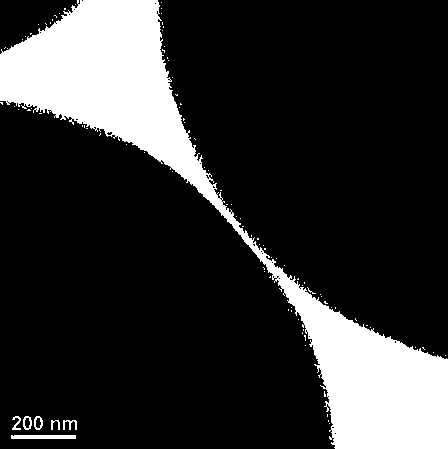

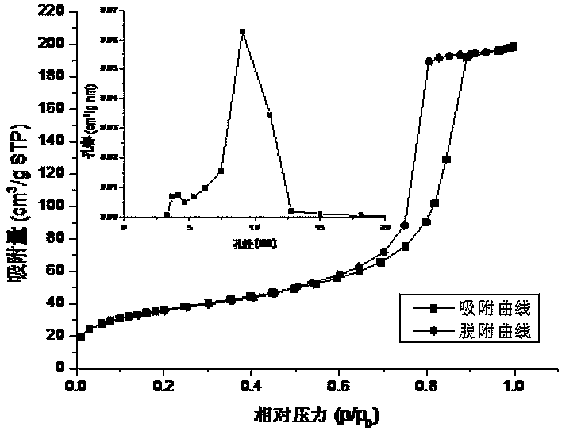

[0027] A preparation method for a core-shell filler applied to liquid chromatography separation and analysis, comprising the following steps:

[0028] (1) Weigh 1g particle size as 1 ~5 The solid silicon spheres are uniformly dispersed in 50 mL of pure water, and the solid silicon spheres and pure water are fully stirred and mixed at room temperature at 15-25° C. to obtain a dispersion.

[0029] (2) Add 1 polydimethyldiallylammonium chloride to the dispersion liquid obtained in step (1) at room temperature at 15-25°C, and stir and mix with ultrasonic to obtain a white emulsion.

[0030] (3) Control the reaction temperature at 100°C, add 3mL of ammonia water to the white emulsion obtained in step (2), adjust the pH of the solution to 10, stir at 300-800r / min, and reflux for 24h.

[0031] (4) After the reaction is over, cool the reactant to room temperature at 15-25°C, centrifuge, wash with water, filter with suction, dry at low temperature (50-80°C), and then calcinate at 5...

Embodiment 2

[0034] A preparation method for a core-shell filler applied to liquid chromatography separation and analysis, comprising the following steps:

[0035] (1) Weigh 5g of particle size as 1 ~5 The solid silicon spheres are uniformly dispersed in 250 mL of pure water, and the solid silicon spheres and pure water are fully stirred and mixed under the condition of 15-25° C. to obtain a dispersion liquid.

[0036] (2) At 15-25°C, add 5-polydimethyldiallylammonium chloride to the dispersion liquid obtained in step (1), stir and mix with ultrasonic to obtain a white emulsion.

[0037] (3) Control the reaction temperature at 90°C, add 20mL ammonia water to the white emulsion obtained in step (2), adjust the pH of the solution to 10.69, stir at 300-800r / min, and reflux for 24h.

[0038] (4) After the reaction is completed, cool the reactant to 15-25°C, centrifuge, wash with water, suction filter, dry at low temperature (50-80°C), and then calcinate at 600°C for 6 hours; Drying at low...

Embodiment 3

[0041] A preparation method for a core-shell filler applied to liquid chromatography separation and analysis, comprising the following steps:

[0042] (1) Weigh 10g of particle size as 1 ~5 The solid silicon spheres are evenly dispersed in 500 mL of pure water, and the solid silicon spheres and pure water are fully stirred and mixed under the condition of 15-25° C. to obtain a dispersion liquid.

[0043] (2) At 15-25°C, add 10 polydimethyldiallylammonium chloride to the dispersion liquid obtained in step (1), stir and mix with ultrasonic to obtain a white emulsion.

[0044] (3) Control the reaction temperature at 80°C, add 75mL of ammonia water to the white emulsion obtained in step (2), adjust the pH of the solution to 12.33, stir at 300-800r / min, and reflux for 18h.

[0045] (4) After the reaction is completed, cool the reactant to 15-25°C, centrifuge, wash with water, suction filter, dry at low temperature (50-80°C), and then calcinate at 700°C for 6 hours; Drying at low...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com