Low-density and high-extrusion-rate PVC fireproof sealing strip and preparation method thereof

A technology of extrusion rate and low density, applied in the field of low density, high extrusion rate PVC fireproof sealing strip and its preparation, can solve the problems of increasing cost, reducing the strength of sealing strip and fireproof ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

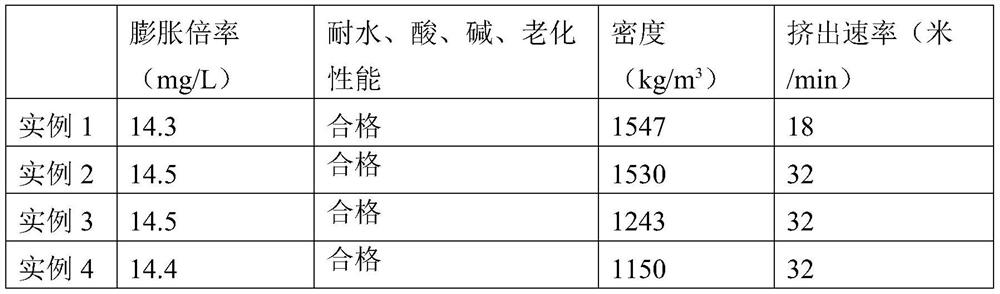

Embodiment 1

[0017] The formula is calculated by weight percentage, SG-5 polyvinyl chloride resin powder 25%, 80 mesh expanded graphite 25%, light calcium carbonate 16.5%, plasticizer 27%, heat stabilizer 1%, flame retardant 4.5% and Processing aid 1%, 200-500 rev / min mixing and stirring for 3-10 minutes, reduce to low speed and stir for 1-5 minutes, after granulation, extrusion molding, cooling, cutting and sticking double-sided adhesive tape to obtain PVC Finished flame retardant sealing strip.

Embodiment 2

[0019] The formula is calculated by weight percentage, SG-5 polyvinyl chloride resin powder 25%, 80 mesh expanded graphite 25%, light calcium carbonate 13.5%, perlite 3%, plasticizer 27%, heat stabilizer 1%, flame retardant 4.5% additive and 1% processing aid, mix and shake at 200-500 rpm for 3-10 minutes, then reduce to low speed and stir for 1-5 minutes, after granulation, extrusion molding, cooling, cutting and pasting double-sided After gluing, the finished PVC flame-retardant sealing strip is obtained.

Embodiment 3

[0021] The formula is calculated by weight percentage, SG-5 polyvinyl chloride resin powder 25%, 80 mesh expanded graphite 25%, light calcium carbonate 9%, perlite 3%, AC foaming agent 1.5%, cell regulator 3% , 27% plasticizer, 1% heat stabilizer, 4.5% flame retardant and 1% processing aid, 200-500 rpm mixing and stirring for 3-10 minutes, then reduce to low speed and stir for 1-5 minutes, after After granulation, extrusion molding, cooling, cutting and sticking double-sided tape, the finished PVC flame-retardant sealing strip is obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com