Glass fiber reinforced nylon 66 composition with high performance and high extrusion rate

An extrusion rate, glass fiber technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

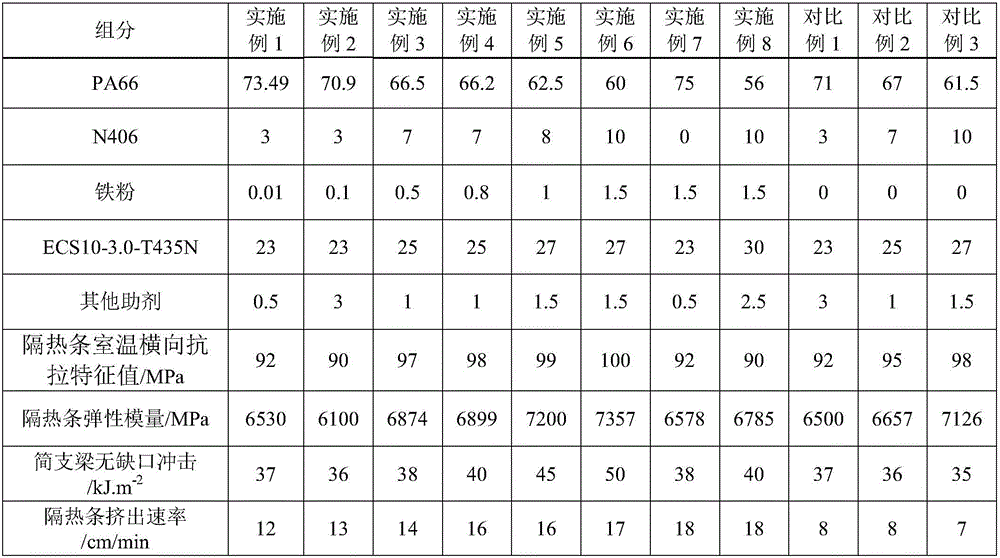

Examples

Embodiment 1

[0033] A high performance and high extrusion rate glass fiber reinforced nylon 66 composition, the composition is made of raw materials comprising the following parts by weight: nylon 66: 73.49 parts, 3 parts of toughening agent, 23 parts of chopped glass fiber, iron powder 0.01 part, 0.1 part of silane coupling agent, 0.1 part of antioxidant and 0.3 part of lubricant.

[0034] The preparation method of this high performance high extrusion rate glass fiber reinforced nylon 66 composition comprises the steps:

[0035] (1) Dry nylon 66 at 120°C for 4 hours, then put toughening agent, iron powder, silane coupling agent, antioxidant, lubricant and dried nylon 66 into a high-speed mixer and mix evenly to form premix;

[0036] (2) The premixed material is added from the main feeding port of the twin-screw extruder (screw diameter is 35mm, aspect ratio L / D=40), and the chopped glass fiber is added from the side feeding port, After melting and extruding, the pellets of glass fiber r...

Embodiment 2

[0039] A high performance and high extrusion rate glass fiber reinforced nylon 66 composition, the composition is made of raw materials comprising the following parts by weight: nylon 66: 70.9 parts, 3 parts of toughening agent, 23 parts of chopped glass fiber, iron powder 0.1 part, 0.6 part of silane coupling agent, 0.6 part of antioxidant and 1.8 part of lubricant.

[0040] The preparation method of this high performance high extrusion rate glass fiber reinforced nylon 66 composition comprises the steps:

[0041] (1) Dry nylon 66 at 120°C for 4 hours, then put toughening agent, iron powder, silane coupling agent, antioxidant, lubricant and dried nylon 66 into a high-speed mixer and mix evenly to form premix;

[0042] (2) The premixed material is added from the main feeding port of the twin-screw extruder (screw diameter is 35mm, aspect ratio L / D=40), and the chopped glass fiber is added from the side feeding port, After melting and extruding, the pellets of glass fiber rei...

Embodiment 3

[0045] A high performance and high extrusion rate glass fiber reinforced nylon 66 composition, the composition is made of raw materials comprising the following parts by weight: nylon 66: 66.5 parts, 7 parts of toughening agent, 25 parts of chopped glass fiber, iron powder 0.5 parts, 0.2 parts of silane coupling agent, 0.2 parts of antioxidant and 0.6 parts of lubricant.

[0046] The preparation method of this high performance high extrusion rate glass fiber reinforced nylon 66 composition comprises the steps:

[0047] (1) Dry nylon 66 at 120°C for 4 hours, then put toughening agent, iron powder, silane coupling agent, antioxidant, lubricant and dried nylon 66 into a high-speed mixer and mix evenly to form premix;

[0048](2) The premixed material is added from the main feeding port of the twin-screw extruder (screw diameter is 35mm, aspect ratio L / D=40), and the chopped glass fiber is added from the side feeding port, After melting and extruding, the pellets of glass fiber ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com