High-speed-extruding oil-proof wear-resisting irradiation crosslinking rubber material and preparation method thereof

A high-speed extrusion, cross-linked rubber technology, used in plastic/resin/wax insulators, organic insulators, conductors, etc. Grinding performance, excellent oil resistance, and the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

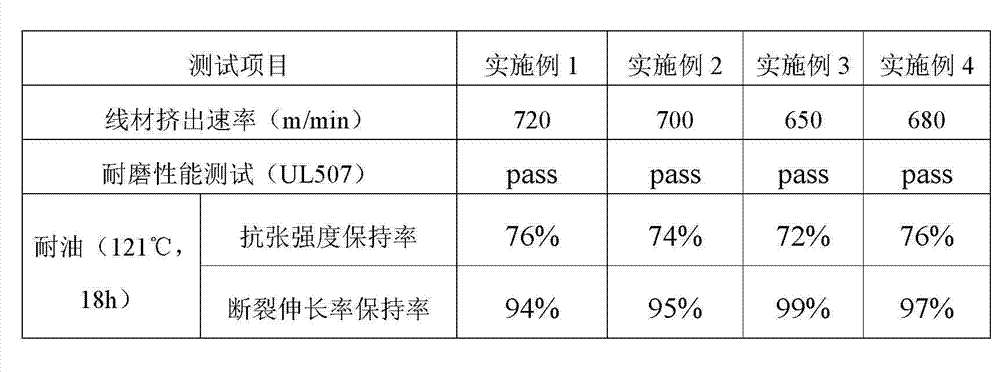

Examples

Embodiment 1

[0035] A high oil-resistant low-smoke halogen-free radiation cross-linked sheath material, which consists of the following components:

[0036] Chlorinated polyethylene: 50 kg, low-density polyethylene: 10 kg, magnesium hydroxide: 10 kg, calcium carbonate: 10 kg, stabilizer: 4 kg, compatibilizer: 4 kg, silicone powder: 3 kg, two Silicon oxide: 1.5 kg, plasticizer: 5 kg, carbon black: 2.5 kg.

[0037] Described chlorinated polyvinyl chloride content is 35%. The polyethylene is linear low density polyethylene. The magnesium hydroxide is surface-modified magnesium hydroxide with a silane coupling agent, and the mesh number is 4000 mesh. Described calcium carbonate is light calcium carbonate, and number of orders is 4000 orders. The stabilizer components are 40 parts of calcium stearate, 20 parts of zinc stearate, 40 parts of tetrakis [β-(3,5-di-tert-butyl-4-hydroxyphenyl) propionate] pentaerythritol ester . The silicone powder components are 60 parts of silicone oil and 40 p...

Embodiment 2

[0042] A high oil-resistant low-smoke halogen-free radiation cross-linked sheath material, which consists of the following components:

[0043] Chlorinated polyethylene: 53 kg, low-density polyethylene: 5 kg, magnesium hydroxide: 12 kg, calcium carbonate: 12 kg, stabilizer: 3 kg, compatibilizer: 4 kg, silicone powder: 3 kg, two Silicon oxide: 2 kg, plasticizer: 3 kg, carbon black: 3 kg.

[0044] Described chlorinated polyvinyl chloride content is 35%. The polyethylene is linear low density polyethylene. The magnesium hydroxide is surface-modified magnesium hydroxide with a silane coupling agent, and the mesh number is 4000 mesh. Described calcium carbonate is light calcium carbonate, and number of orders is 4000 orders. The stabilizer components are 60 parts of calcium stearate, 20 parts of zinc stearate, 20 parts of tetrakis [β-(3,5-di-tert-butyl-4-hydroxyphenyl) propionate] pentaerythritol ester . The silicone powder components are 50 parts of silicone oil and 50 parts ...

Embodiment 3

[0047] A high oil-resistant low-smoke halogen-free radiation cross-linked sheath material, which consists of the following components:

[0048] Chlorinated polyethylene: 54 kg, low-density polyethylene: 5 kg, magnesium hydroxide: 14 kg, calcium carbonate: 6 kg, stabilizer: 4 kg, compatibilizer: 4 kg, silicone powder: 4 kg, two Silicon oxide: 3 kg, plasticizer: 4 kg, carbon black: 2 kg.

[0049] Described chlorinated polyvinyl chloride content is 35%. The polyethylene is linear low density polyethylene. The magnesium hydroxide is surface-modified magnesium hydroxide with a silane coupling agent, and the mesh number is 3000 mesh. Described calcium carbonate is light calcium carbonate, and number of orders is 4000 orders. The stabilizer components are 50 parts of calcium stearate, 20 parts of zinc stearate, 30 parts of tetrakis [β-(3,5-di-tert-butyl-4-hydroxyphenyl) propionate] pentaerythritol ester . The silicone powder components are 50 parts of silicone oil and 50 parts o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| whiteness | aaaaa | aaaaa |

| degree of grafting | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com