Preparation method of seasoned gluten

A technology of gluten and flour flocculation, which is applied in plant protein processing, food science, etc., can solve the problems of short taste retention time of extruded seasoned gluten, easy deterioration, instability of extruded seasoned gluten, etc., to improve production stability, Not easy to agglomerate, great application value effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

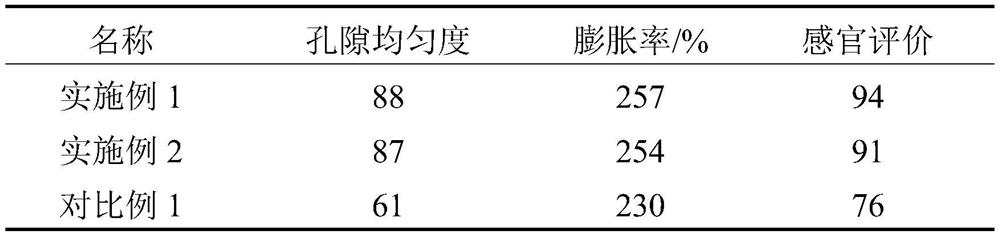

Examples

Embodiment 1

[0019] A seasoning gluten is composed of the following raw materials by weight: 650 parts of wheat flour, 60 parts of edible salt, 50 parts of fructose powder, 30 parts of chili powder, 4 parts of monoglyceride, 80 parts of edible oil, 50 parts of sesame oil, and 200 parts of water .

[0020] The preparation method of seasoning gluten, comprises the following steps:

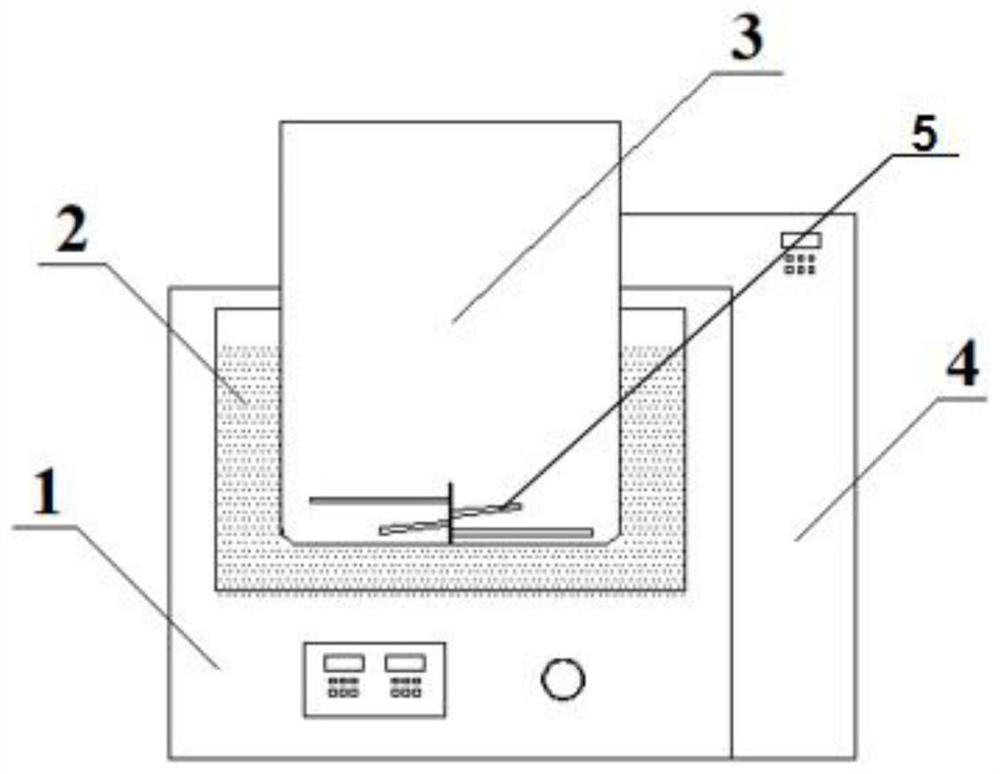

[0021] S1: Preparation of flour flocs: Weigh wheat flour, edible salt, fructose powder, monoglyceride and water according to the above parts by weight, and add such as figure 1 Mix in the powder bucket of the ultrasonic assisted powdering device, the ultrasonic power of the ultrasonic device is 1.2kw, the screw speed is about 800r / min, and the powdering time is 30s, and the flour wadding is obtained;

[0022] S2: Extrusion and puffing molding: Pour the flour flocs prepared in step S1 into the powder hopper of the extrusion puffing machine, start the extrusion puffing machine to prepare the semi-finished product ...

Embodiment 2

[0025] A seasoning gluten is composed of the following raw materials by weight: 650 parts of wheat flour, 60 parts of edible salt, 50 parts of fructose powder, 30 parts of chili powder, 4 parts of monoglyceride, 80 parts of edible oil, 50 parts of sesame oil, and 200 parts of water .

[0026] The preparation method of seasoning gluten, comprises the following steps:

[0027] S1: Preparation of flour flocs: Weigh wheat flour, edible salt, fructose powder, monoglyceride and water according to the above parts by weight, and add such as figure 1 Mix in the powder bucket of the ultrasonic assisted powdering device, the ultrasonic power of the ultrasonic device is 1.2kw, the screw speed is about 800r / min, and the powdering time is 40s, and the flour wadding is obtained;

[0028] S2: Extrusion and puffing molding: Pour the flour flocs prepared in step S1 into the powder hopper of the extrusion puffing machine, start the extrusion puffing machine to prepare the semi-finished product ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com