Detachable gradual type right-angle rubber pipe extrusion die pre-forming segment design method

A design method and extrusion die technology, which are applied in the design field of the pre-forming section of a detachable progressive right-angle rubber hose extrusion die, can solve problems such as high energy consumption, achieve strong adaptability, reduce extrusion energy consumption, and improve extrusion rate. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The technical solutions of the present invention will be further described below in conjunction with the embodiments shown in the accompanying drawings.

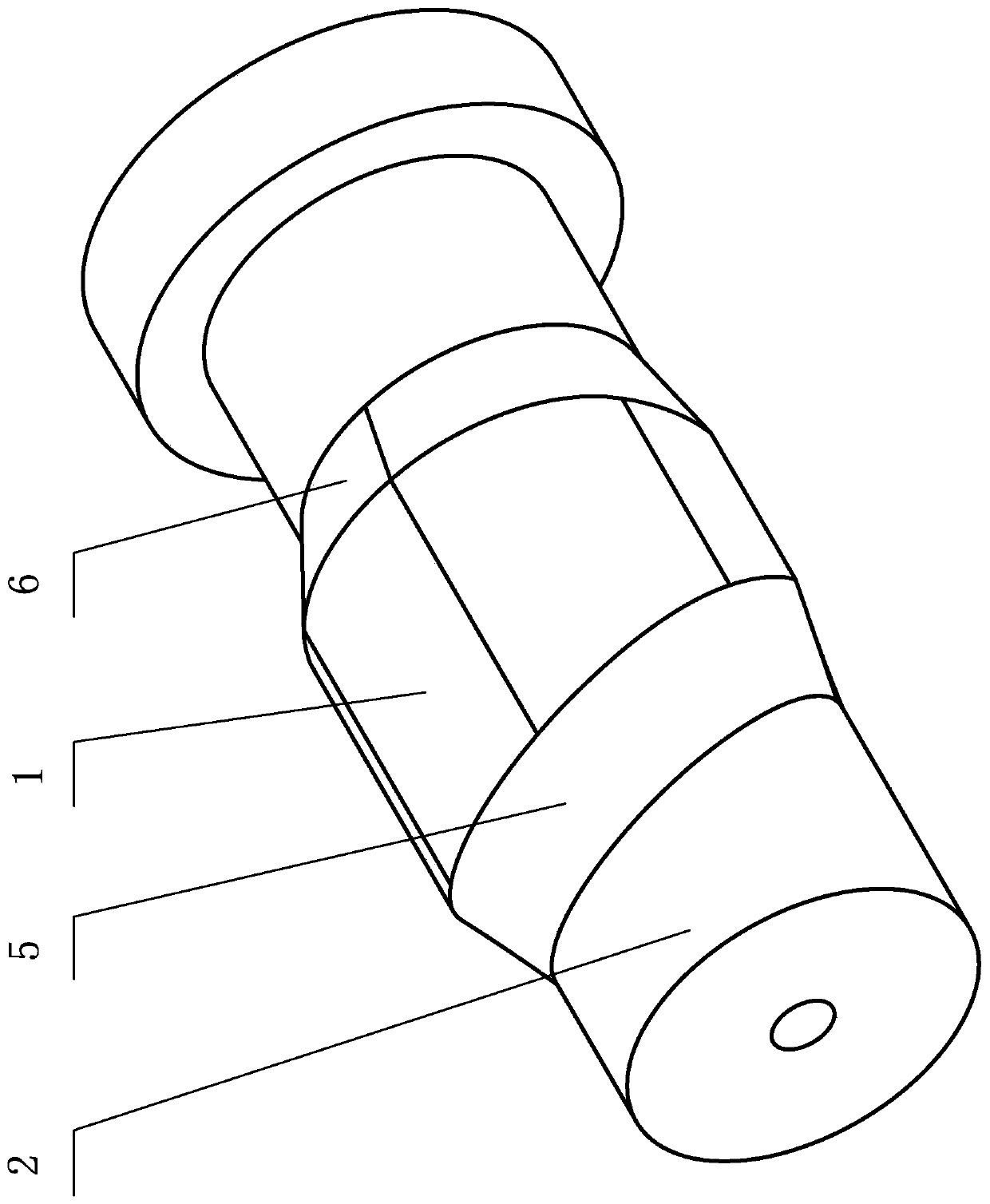

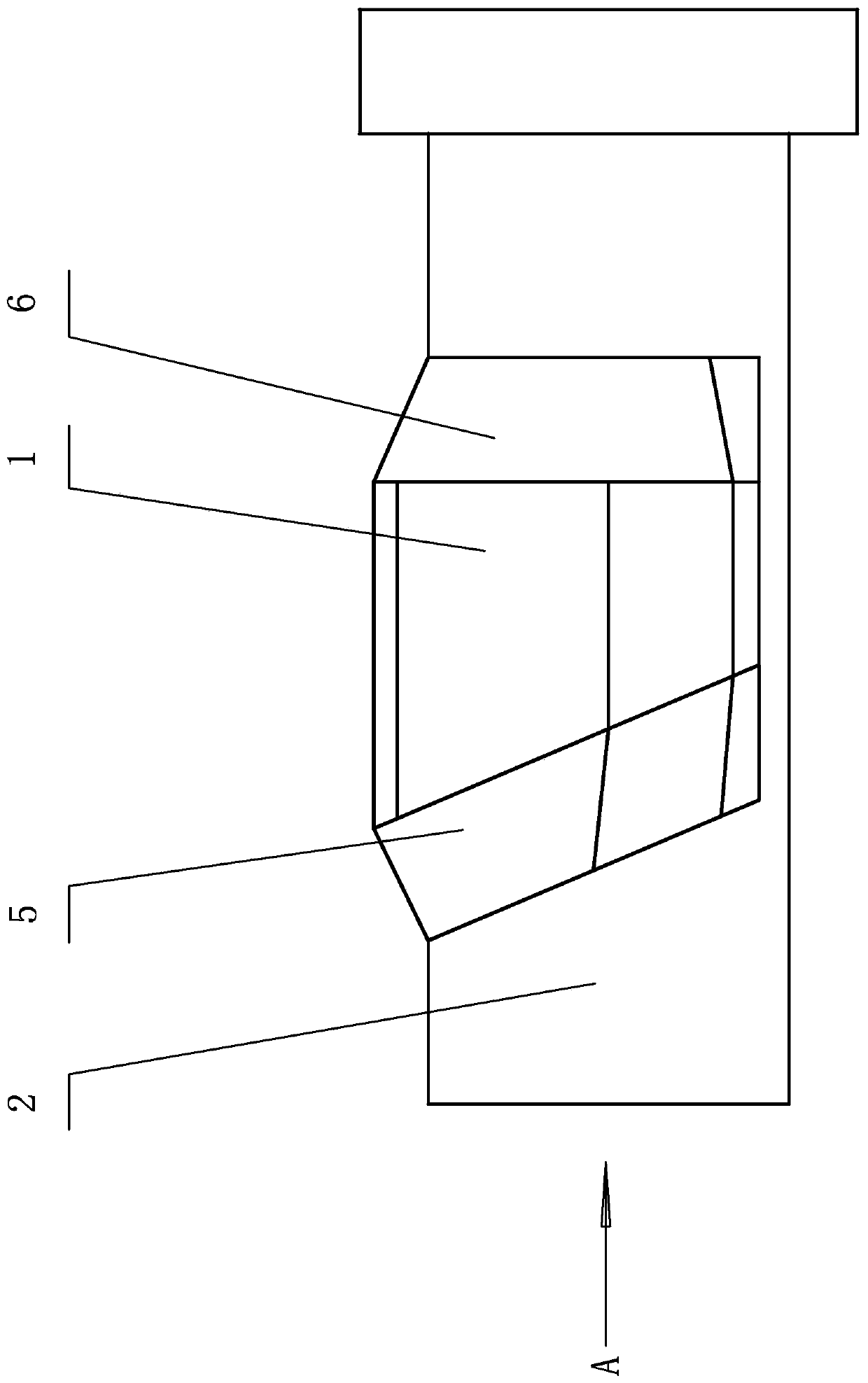

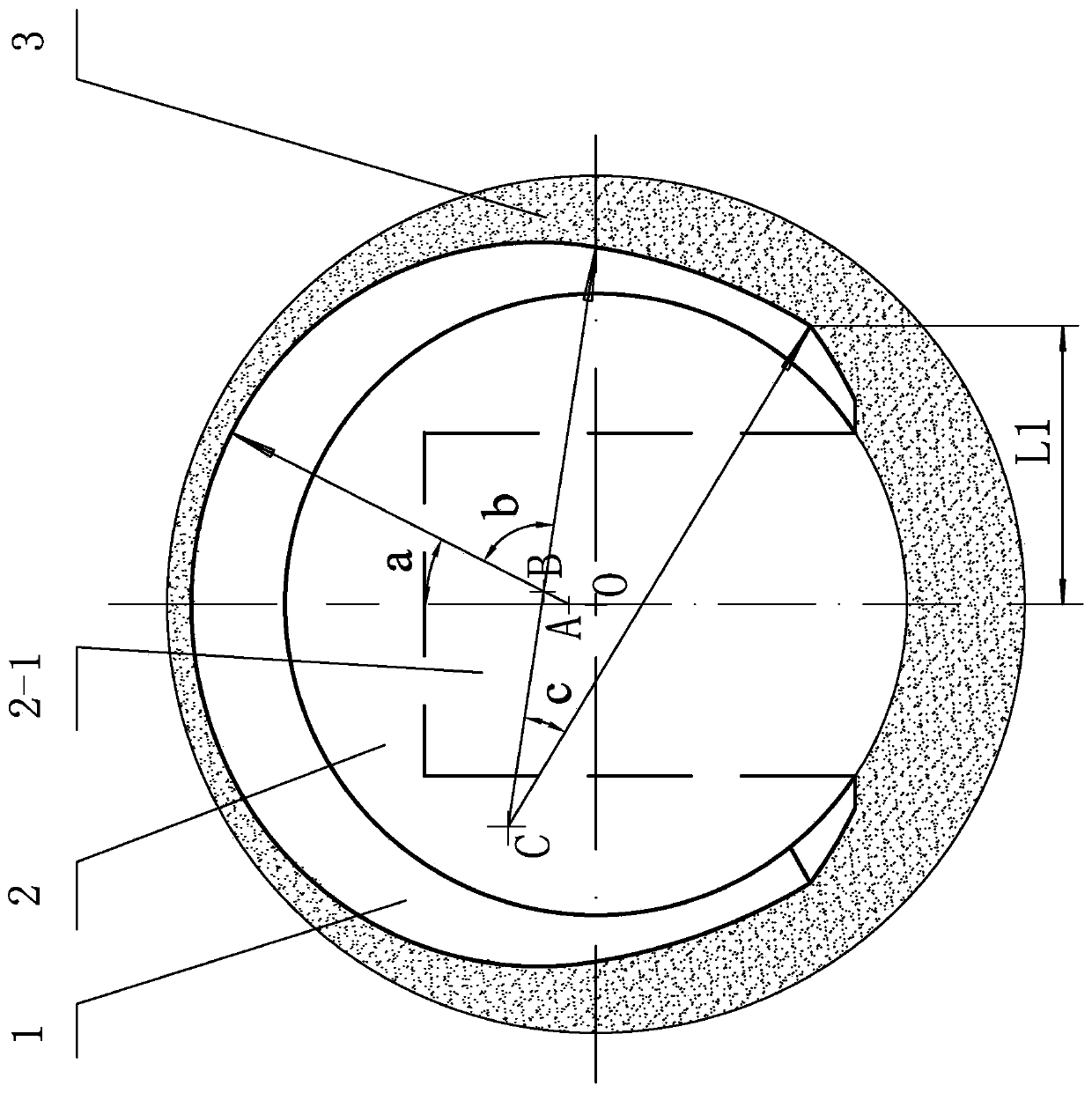

[0019] The design method of the preforming section of the detachable progressive right-angle rubber hose extrusion die of the present invention is to design the flow-distributing and flow-blocking structure in the cavity of the pre-forming section as a flow-distributing and flow-blocking ring block 1 that is snap-fitted and fastened to the middle of the mold core 2 with screws. , the clamping structure includes a square card slot 4 set in the center of the bottom of the shunt block 1 and a square seat 2-1 set in the lower part of the mold core 2, the block ring surface of the shunt block 1 The design is symmetrical on the left and right sides, and the width of the flow-blocking ring surface on each side gradually decreases from top to bottom. The front end of the ring block 1 is designed as a slope with the bottom slo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com