Single-component high-temperature-soaking-resistant silicone adhesive and preparation method and application thereof

A technology of silicone glue and acyloxysilane, which is applied in adhesives, climate change adaptation, non-polymer adhesive additives, etc., can solve the problem of unfavorable biological health organotin catalysts, silicone glue with poor high temperature and water immersion resistance, and limited products Export and other issues, to achieve the effect of long storage shelf life, improved mechanical properties, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

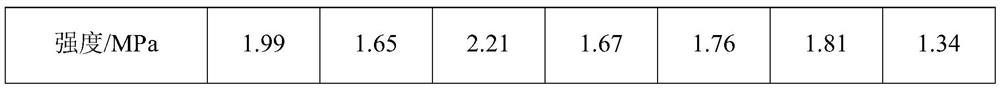

Examples

Embodiment 1

[0049] The raw material components of silicone glue: 100 parts of dihydroxypolydimethylsiloxane with a viscosity of 135000cP, 20 parts of dihydroxypolydimethylsiloxane with a viscosity of 750cP, 3.8 parts of methyltriacetoxysilane, 1.1 parts of ethyl triacetoxysilane, 0.005 parts of tetrabutyl titanate, 12.5 parts of fumed white carbon black processed by D4, vinyl silsesquioxane copolymer (particle size is 250nm, molecular weight 1912g / mol, polymerized Degree 4, molecular weight distribution is 1.7) 14.5 parts.

[0050] Preparation:

[0051] 1) Mix dihydroxypolydimethylsiloxane, methyltriacetoxysilane, and ethyltriacetoxysilane with two viscosities according to the above ratio, and stir evenly;

[0052] 2) Add the above amount of D4-treated fumed silica to the mixture obtained in step 1), and mix and stir evenly;

[0053] 3) Add the above amount of catalyst and vinyl silsesquioxane copolymer to the mixture obtained in step 2), mix and stir evenly to obtain silicone glue.

Embodiment 2

[0055] The raw material components of silicone glue: 100 parts of dihydroxypolydimethylsiloxane with a viscosity of 135000cP, 11.7 parts of dihydroxypolydimethylsiloxane with a viscosity of 750cP, dimethylpolydimethylsiloxane with a viscosity of 100cP 26.8 parts of polysiloxane, 8.4 parts of mixture of oligoethylacetoxysilane and oligomethylacetoxysilane with a degree of polymerization of 3 (among them, oligoethylacetoxysilane and oligomethylacetoxy The weight ratio of base silane is 1:1), 0.005 parts of tetrabutyl titanate, 15.5 parts of untreated white carbon black, vinyl silsesquioxane copolymer (particle size is 300nm, molecular weight 1586g / mol, degree of polymerization 2. The molecular weight distribution is 1.75) 10 parts.

[0056] The preparation process refers to Example 1. The difference from Example 1 is that in step 1) of this example, dihydroxypolydimethylsiloxane, dimethylpolydimethylsiloxane, oligomerization The mixture of ethyl and methyl acetoxysilane is mixe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com