Method for recycling polyvinylidene fluoride plastic

A polyvinylidene fluoride, recycling technology, applied in the field of new functional materials, can solve the problems of weather resistance, UV resistance, chemical stability and mechanical properties discount, performance is not significantly improved, polyvinylidene fluoride is difficult to degrade, etc. Achieve appearance and physical and mechanical properties guarantee, eliminate surface defects, good compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

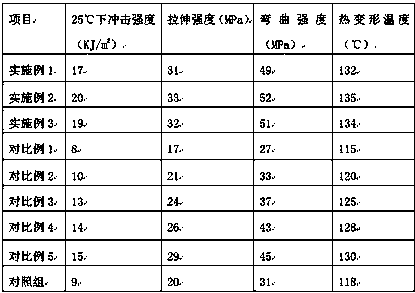

Examples

Embodiment 1

[0020] A method for recycling polyvinylidene fluoride plastics, which comprises removing impurities from waste polyvinylidene fluoride plastics and putting them into a pulverizer to pulverize them into small particles with a particle size between 1-3 millimeters, adding the prepared composite additives, Put it into a high-speed mixer for blending. After mixing, put the premixed material in an oven at 110°C to dry for 4 hours, then send it into a twin-screw extruder, add a coupling agent, and jointly extrude and granulate. The pellets are further processed into various polyvinylidene fluoride plastic products, and the preparation method of the composite additive comprises the following steps:

[0021] (1) Weigh 18 grams of sodium silicate and add it to the beaker, add 80 ml of sodium hydroxide aqueous solution to the beaker, stir to dissolve, weigh 0.25-mmol cobalt chloride hexahydrate and put it in the beaker, and continue to stir for 20 minutes ;

[0022] (2) Weigh 0.15 mill...

Embodiment 2

[0032] A method for recycling polyvinylidene fluoride plastics, which comprises removing impurities from waste polyvinylidene fluoride plastics and putting them into a pulverizer to pulverize them into small particles with a particle size between 1-3 millimeters, adding the prepared composite additives, Put it into a high-speed mixer for blending. After mixing, put the premixed material in an oven at 112°C to dry for 5 hours, then send it into a twin-screw extruder, add a coupling agent, and jointly extrude and granulate. The pellets are further processed into various polyvinylidene fluoride plastic products, and the preparation method of the composite additive comprises the following steps:

[0033] (1) Weigh 19 grams of sodium silicate and add it to the beaker, add 85 milliliters of sodium hydroxide aqueous solution to the beaker, stir and dissolve, weigh 0.28 mmol of cobalt chloride hexahydrate and place it in the beaker, and continue to stir for 25 minutes;

[0034] (2) We...

Embodiment 3

[0044] A method for recycling polyvinylidene fluoride plastics, which comprises removing impurities from waste polyvinylidene fluoride plastics and putting them into a pulverizer to pulverize them into small particles with a particle size between 1-3 millimeters, adding the prepared composite additives, Put it into a high-speed mixer for blending. After mixing, put the premixed material in an oven at 115°C to dry for 6 hours, then send it into a twin-screw extruder, add a coupling agent, and co-extrude and granulate. The pellets are further processed into various polyvinylidene fluoride plastic products, and the preparation method of the composite additive comprises the following steps:

[0045] (1) Weigh 20 grams of sodium silicate and add it to the beaker, add 90 ml of sodium hydroxide aqueous solution to the beaker, stir and dissolve, weigh 0.30 mmol of cobalt chloride hexahydrate and place it in the beaker, and continue to stir for 30 minutes;

[0046] (2) Weigh 0.18 milli...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com