High-strength magnesium-zinc-manganese-yttrium magnesium alloy material

A high-strength, magnesium alloy technology, applied in the field of light metal materials, can solve the problems of harsh requirements, complex processing, and inability to apply, and achieve the effects of reducing deformation resistance, simple process, and inhibiting coarse compounds

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

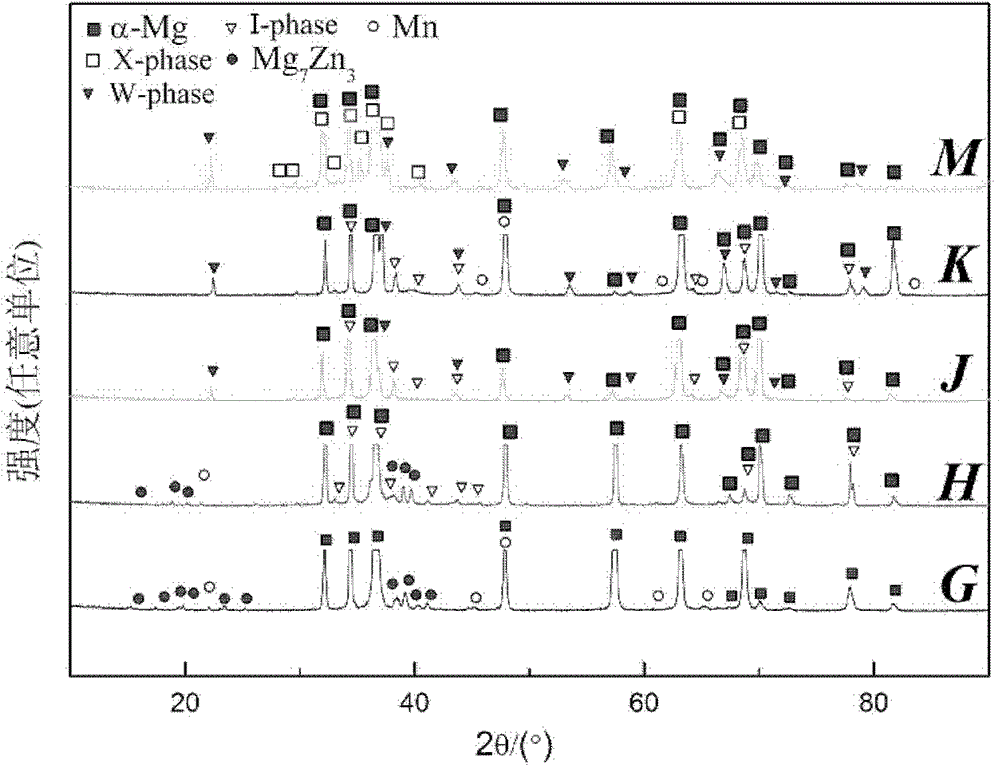

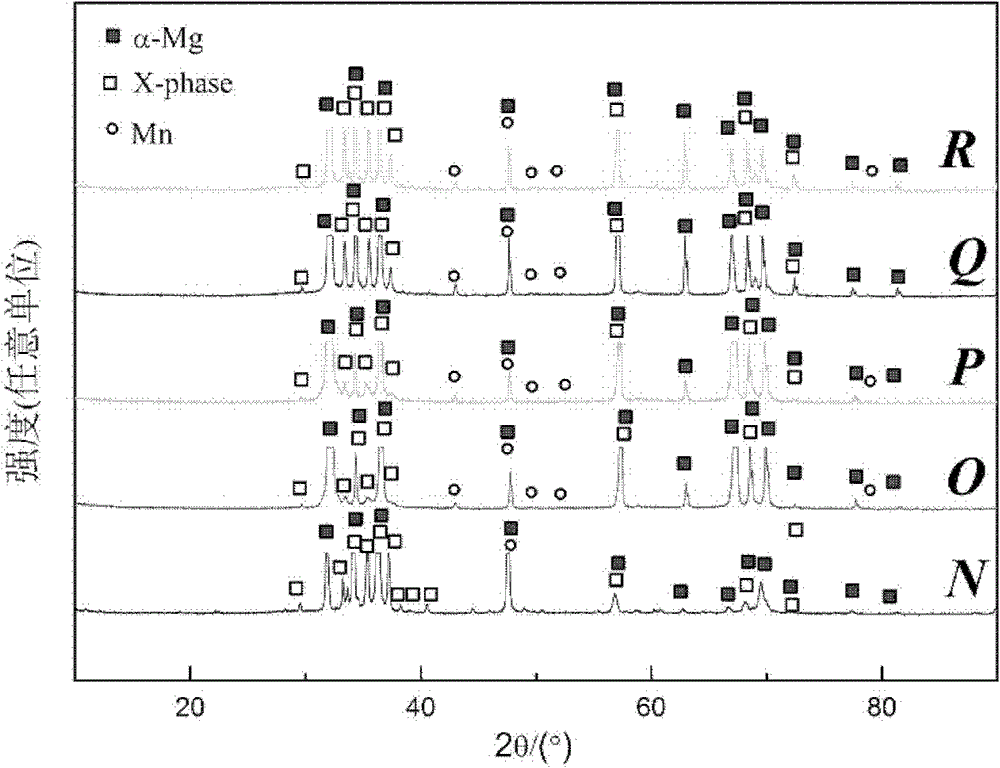

Image

Examples

Embodiment 1

[0030] Example 1: Hot-extruded high-strength magnesium-zinc-manganese-yttrium-magnesium alloy material, the weight percentage of each component of the magnesium alloy is shown in Table 1.

[0031] Table 1 The chemical composition of this magnesium alloy material (the following is the mass percentage content)

[0032]

Embodiment 2

[0033] Example 2: Hot extruded high-strength magnesium-zinc-manganese-yttrium-magnesium alloy material, the weight percentage of each component of the magnesium alloy is shown in Table 2.

[0034]Table 2 The chemical composition of this magnesium alloy material (the following is the mass percentage content)

[0035]

Embodiment 3

[0036] Example 3: Hot extrusion of high-strength magnesium-zinc-manganese-yttrium-magnesium alloy material, see Table 3 for the weight percentage of each component of the magnesium alloy.

[0037] Table 3 The chemical composition of this magnesium alloy material (the following are mass percentages)

[0038]

[0039]

[0040] Get the composition formula of above-mentioned embodiment, obtain magnesium alloy material of the present invention with following method:

[0041] 1. Alloy smelting and casting

[0042] Alloys were formulated according to the ingredients of the above examples, and cast by semi-continuous casting. The raw materials are industrial pure magnesium ingots, industrial pure zinc, Mg-30.83% Y rare earth master alloy and Mg-4.1% Mn master alloy, which are carried out on semi-continuous casting equipment. Firstly, industrial pure magnesium is heated and melted in a resistance crucible boiler, and the masterbatch is completely melted when the temperature is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com