Method for preparing rare earth doped beta-NaYF4 upconversion nanocrystal with size of less than 8nm

A rare earth doping, nanocrystalline technology, applied in nanotechnology, nanooptics, nanotechnology, etc., to achieve high repeatability and promote transformation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] (1) First, weigh 1mmol RECl of rare earth 3 ·6H 2 O (Y:Yb:Er=80:18:2, molar ratio) was added to 6 mL of oleic acid and 15 mL of l-octadecene solution. Under the protection of argon, stir and heat to 150°C and keep it warm for 30min. After the rare earth particles are completely dissolved, cool naturally to room temperature.

[0027](2) Then, successively dissolve 2.5mmol sodium oleate and 4mmol NH 4 10 mL methanol solution of F was added dropwise to the reaction system, stirred and heated to 60°C and kept for 60 min.

[0028] (3) Subsequently, under the protection of argon, the solution was stirred and heated to 300°C, kept for 0 min, and then naturally cooled to room temperature.

[0029] (4) Centrifuge with a centrifuge, wash and centrifuge repeatedly with cyclohexane-ethanol three times, and finally disperse in cyclohexane or dry in an oven.

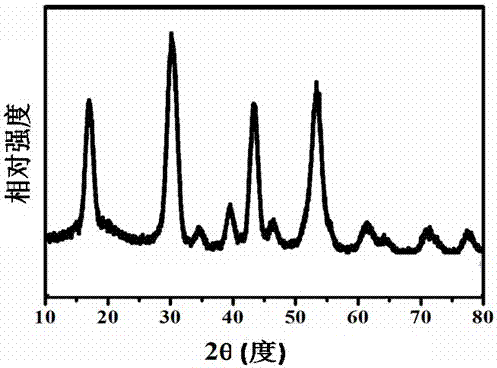

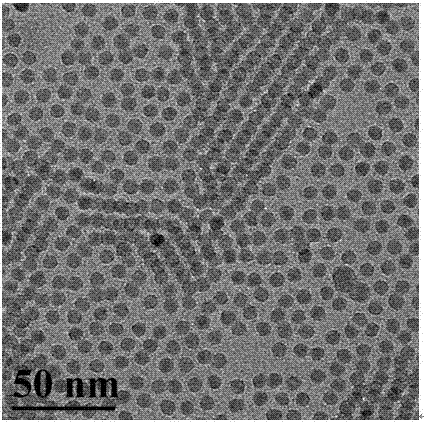

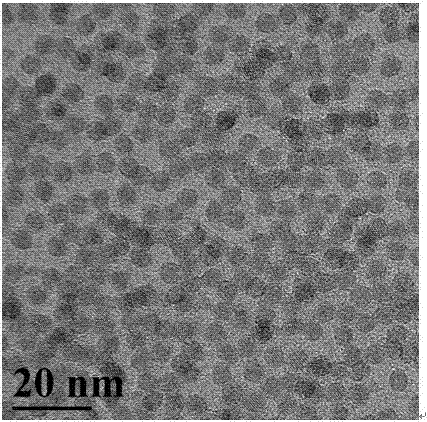

[0030] (5) Under the experimental conditions, uniformly dispersed pure phase β-NaYF with a size of 7.0 nm can be obtained...

Embodiment 2

[0032] (1) First, weigh 1mmol RE(Ac) of rare earth 3 ·nH 2 O (Y:Yb:Tm=78:18:4, molar ratio) was added to 6 mL of oleic acid and 15 mL of 1-octadecene solution. Under the protection of argon, stir and heat to 140°C and keep it warm for 30min. After the rare earth particles are completely dissolved, cool naturally to room temperature.

[0033] (2) Then, successively dissolve 2.5mmol sodium oleate and 4mmol NH 4 10 mL of methanol solution of F was added dropwise to the reaction system, stirred and heated to 50 °C and kept for 60 min.

[0034] (3) Subsequently, under the protection of argon, the solution was stirred and heated to 260°C, kept for 30min, and then cooled to room temperature naturally.

[0035] (4) Centrifuge with a centrifuge, wash and centrifuge repeatedly with cyclohexane-ethanol three times, and finally disperse in cyclohexane or dry in an oven.

[0036] (5) Under the experimental conditions, uniformly dispersed pure phase β-NaYF with a size of 5.1 nm can be o...

Embodiment 3

[0038] (1) First, weigh 1mmol RECl of rare earth 3 ·6H 2 O (Y:Yb:Ho=75:20:5, molar ratio) was added to 6 mL of oleic acid and 15 mL of l-octadecene solution. Under the protection of argon, stir and heat to 155°C and keep it warm for 30 minutes. After the rare earth particles are completely dissolved, cool naturally to room temperature.

[0039] (2) Then, successively dissolve 2.5mmol sodium oleate and 4mmol NH 4 10 mL methanol solution of F was added dropwise to the reaction system, stirred and heated to 60°C and kept for 60 min.

[0040] (3) Subsequently, under the protection of argon, the solution was stirred and heated to 290°C, kept for 5 minutes, and then cooled to room temperature naturally.

[0041] (4) Centrifuge with a centrifuge, wash and centrifuge repeatedly with cyclohexane-ethanol three times, and finally disperse in cyclohexane or dry in an oven.

[0042] (5) Under the experimental conditions, uniformly dispersed pure phase β-NaYF with a size of 7.8nm can be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com