Method for synthesis of nanometer ZSM-5 molecular sieve from mother liquor flocculate

A technology of ZSM-5 and molecular sieve, which is applied in the direction of nanotechnology, nanotechnology, nanotechnology, etc. for materials and surface science, can solve the problems of high water content and low content of effective components, and reduce the cost of raw materials and improve Nucleation rate, effect of reducing nucleation activation energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

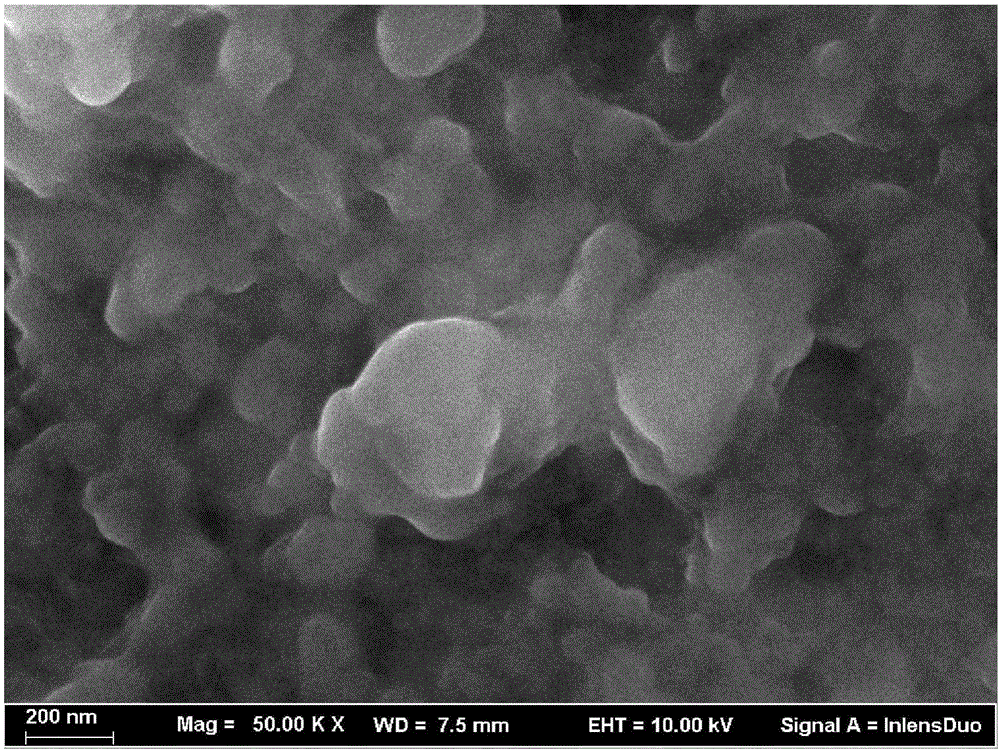

Embodiment 1

[0045] The mother liquor separated after the crystallization in Comparative Example 1 is flocculated to obtain mother liquor floc 50.2g (silicon dioxide: 37.5%; Sodium oxide: 16%) mixed with 130.2g water, add 0.44g sodium hydroxide, stir until Completely dissolve, add 1.1g of sodium metaaluminate into the above solution and stir until completely dissolved. Slowly add 130g of silica sol dropwise to the above mixed solution under stirring conditions to form aluminosilicate gel A; weigh a certain amount of tetrapropylammonium hydroxide, the added tetrapropylammonium hydroxide and silicon aluminum The mass ratio of silicon dioxide in the hydrochloride gel is 0.25. Dissolve the above tetrapropylammonium hydroxide in 30.8g of deionized water and stir until completely dissolved to obtain a mixed solution B. Slowly add solution B to A under stirring conditions Make the mixture uniform in the gel, and finally transfer the mixture into a polytetrafluoroethylene-lined stainless steel cry...

Embodiment 2

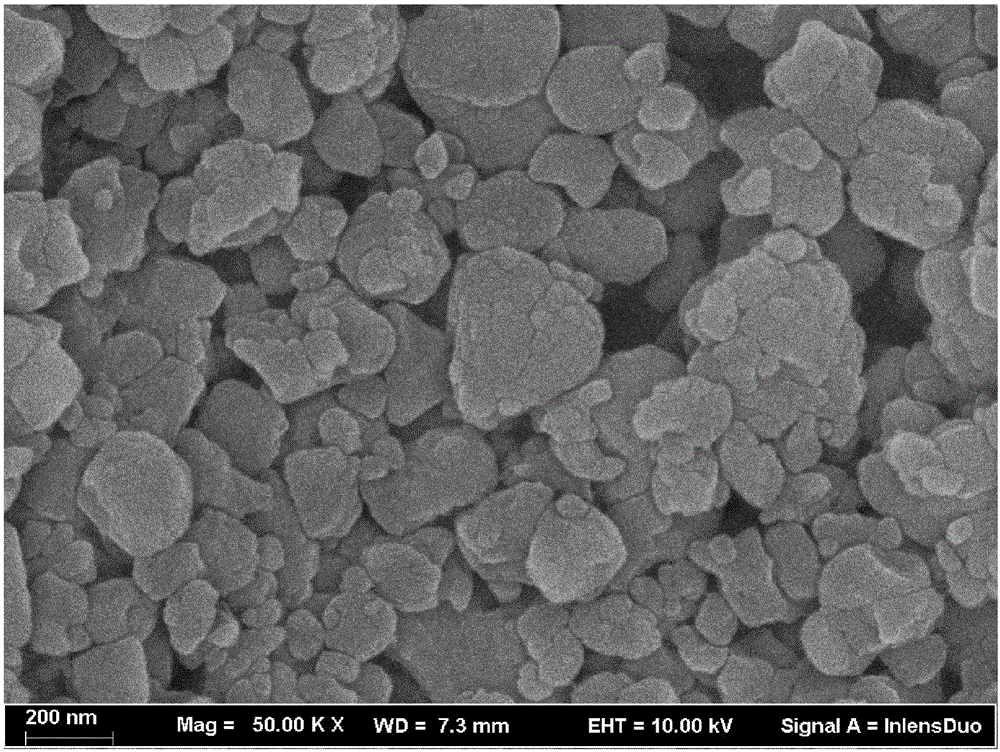

[0049] The separated mother liquor flocculation after the crystallization in comparative example 2 obtains mother liquor floc 51.4g (silicon dioxide: 40%; Sodium oxide: 14.6%) mixes with 130.2g water, adds 0.9g sodium hydroxide, stirs to Completely dissolve, add 1.2g of sodium metaaluminate into the above solution and stir until completely dissolved. Slowly add 125g of silica sol dropwise to the above mixed solution under stirring conditions to form aluminosilicate gel A; weigh a certain amount of tetrapropylammonium hydroxide, the added tetrapropylammonium hydroxide and silicon aluminum The mass ratio of silicon dioxide in the hydrochloride gel is 0.25. Dissolve the above tetrapropylammonium hydroxide in 30.8g of deionized water and stir until completely dissolved to obtain a mixed solution B. Slowly add solution B to A under stirring conditions Make the mixture uniform in the gel, and finally transfer the mixture into a polytetrafluoroethylene-lined stainless steel crystalli...

Embodiment 3

[0053] The mother liquor separated after the crystallization in Comparative Example 3 was flocculated to obtain mother liquor floc 52.3g (silicon dioxide: 40%; sodium oxide: 13.9%) mixed with 130.2g water, adding 1.1g sodium hydroxide, stirring until Completely dissolve, add 1.2g of sodium metaaluminate into the above solution and stir until completely dissolved. Slowly add 120g of silica sol dropwise to the above mixed solution under stirring conditions to form aluminosilicate gel A; weigh a certain amount of tetrapropylammonium hydroxide, and the added tetrapropylammonium hydroxide and silicon aluminum The mass ratio of silicon dioxide in the hydrochloride gel is 0.25. Dissolve the above tetrapropylammonium hydroxide in 30.8g of deionized water and stir until completely dissolved to obtain a mixed solution B. Slowly add solution B to A under stirring conditions Make the mixture uniform in the gel, and finally transfer the mixture into a polytetrafluoroethylene-lined stainles...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com