Continuous bubbling carbonizing new process for producing super fine active calcium carbonate

A technology of activated calcium carbonate and new process, applied in the direction of calcium carbonate/strontium/barium, etc., can solve the problems of narrow particle size distribution, large equipment investment, complex technology, etc., to achieve good stability, high equipment production efficiency, and optimized process The effect of the condition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

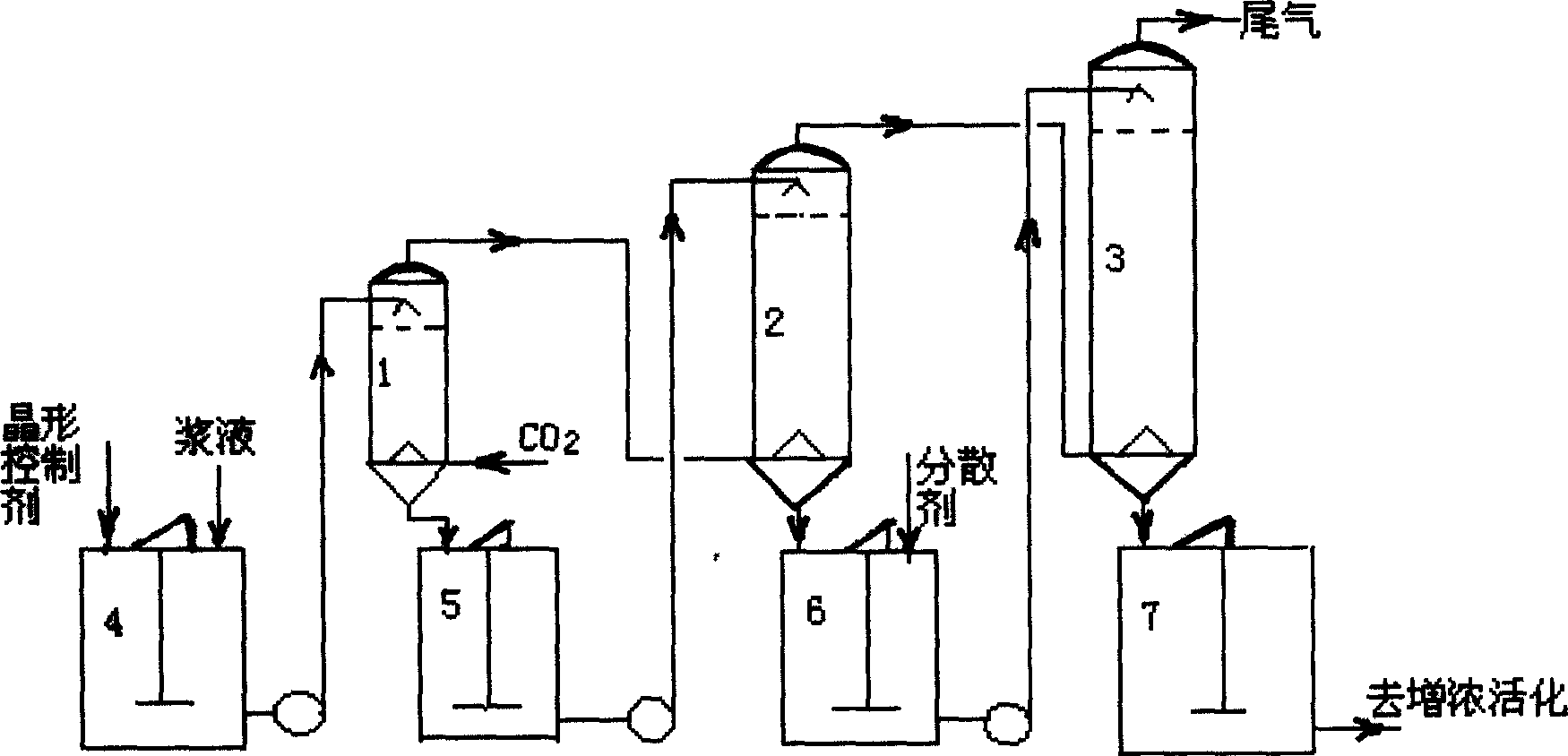

[0016] Such as figure 1 As shown, a pre-carbonization tower (1) is provided, the pre-carbonization tower (1), No. Tower (2) has an effective volume of 15 liters, and No. two carbonization towers (3) has an effective volume of 25 liters. Feed CO into the pre-carbonization tower (1) 2 High-concentration carbonized gas with a content of 98% and a flow rate of 4.2m 3 / min, the gas-liquid material between the towers adopts co-current operation, and the Ca(OH) of 100 liters of concentration 10% (mass concentration) is taken 2 slurry, the Ca(OH) 2 The slurry passes through the refined slurry tank (4), pre-carbonization tower (1), No. 1 slurry tank (5), No. 1 carbonization tower (2), No. 2 slurry tank (6), and No. tower (3) and clinker tank (7), the carbonized gas passes through the pre-carbonized tower (1), No. 1 carbonized tower (2) and No. Top emptying. Ca(OH) 2 When the slurry enters the fine slurry tank (4), continuously add 400 gram of sodium sulfate and 270 gram of sodiu...

Embodiment 2

[0018] A pre-carbonization tower (1) is provided, the pre-carbonization tower (1), No. 1 carbonization tower (2) and No. 2 carbonization tower (3) are connected in series, the pre-carbonization tower (1) has an effective volume of 5 liters, and the No. 1 carbonization tower (2 ) effective volume of 15 liters, No. two carbonization tower (3) effective volume of 25 liters. Feed CO into the pre-carbonization tower (1) 2 High-concentration carbonized gas with a content of 80% and a feed rate of 4.2m 3 / min, the gas-liquid material between the towers adopts cross-flow operation, and 200 liters of Ca(OH) with a temperature of 15°C and a concentration of 10% are taken 2 slurry, the Ca(OH) 2 The slurry passes through the refined slurry tank (4), the pre-carbonization tower (1), the No. 1 slurry tank (5), the No. 1 carbonization tower (2), the No. 2 slurry tank (6), and the No. Carbonization tower (3) and clinker tank (7), carbonization gas passes through pre-carbonization tower (1)...

Embodiment 3

[0020] Such as figure 1 As shown, a pre-carbonization tower (1) is provided, the pre-carbonization tower (1), No. Tower (2) has an effective volume of 15 liters, and No. two carbonization towers (3) has an effective volume of 25 liters. Feed CO into the pre-carbonization tower (1) 2 High-concentration carbonized gas with a content of 70% and a feed rate of 4.2m 3 / min, the gas-liquid materials between the towers are operated in parallel, and 200 liters of Ca(OH) with a temperature of 18°C and a concentration of 8% are taken. 2 slurry, the Ca(OH) 2 The slurry passes through the refined slurry tank (4), pre-carbonization tower (1), No. 1 slurry tank (5), No. 1 carbonization tower (2), No. 2 slurry tank (6), and No. Carbonization tower (3) and clinker tank (7), carbonization gas passes through pre-carbonization tower (1), No. 1 carbonization tower (2) and No. The top of the tower is emptied. Ca(OH) 2 When the slurry enters the fine slurry tank (4), continuously add 640 g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com