Heat treatment method and device for reducing internal residual stress of gh4096 alloy thin-wall disc ring

An internal residual stress, thin-walled disk technology, applied in heat treatment furnaces, heat treatment equipment, quenching devices, etc., can solve the problems of reducing the cooling rate of the workpiece, reducing the material properties, etc., to reduce the barrier, improve the cooling uniformity, and solve the deformation problem. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

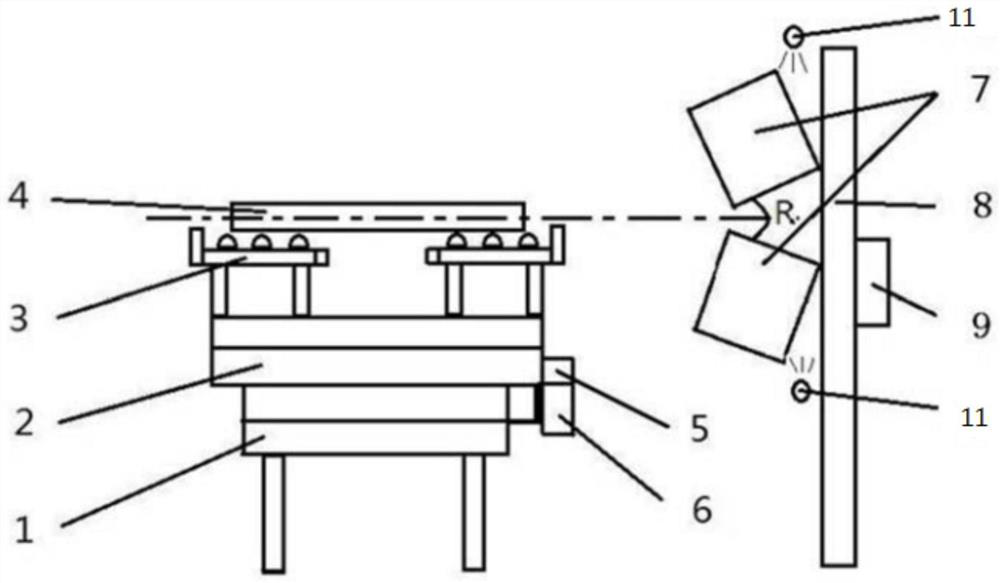

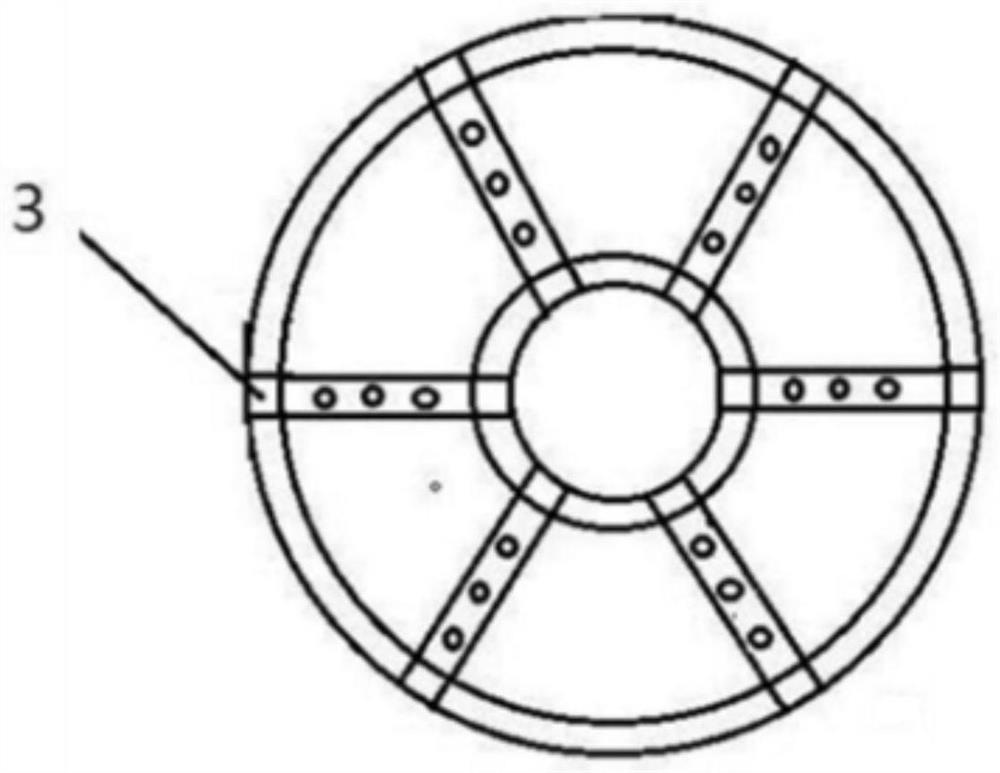

[0027] figure 1 Schematic diagram of the device structure of the present invention, as figure 1 As shown, this embodiment provides a device for reducing the internal residual stress of the GH4096 alloy thin-walled disk ring, and the device includes a platform base 1, a slewing support 2, a rotary table 3, a reducer 5, a motor 6, and a fan 7 , Fan bracket 8, control panel 9, spraying device 11.

[0028] The slewing support 2 is located above the platform base 1 and is connected to the platform base 1 in rotation; the motor 6 is fixed on the platform base 1, and the output end of the motor 6 is connected to the reducer 5; the reducer 5 is connected to the slewing support 2 to drive the slewing support 2 to rotate ; The upper end of the slewing support 2 is provided with a rotary table 3, and the rotary table 3 is used to support the workpiece 4.

[0029] The fan 7 is installed on the fan bracket 8 and is controlled by the control panel 9; the air inlet of the fan 7 is provided...

Embodiment 2

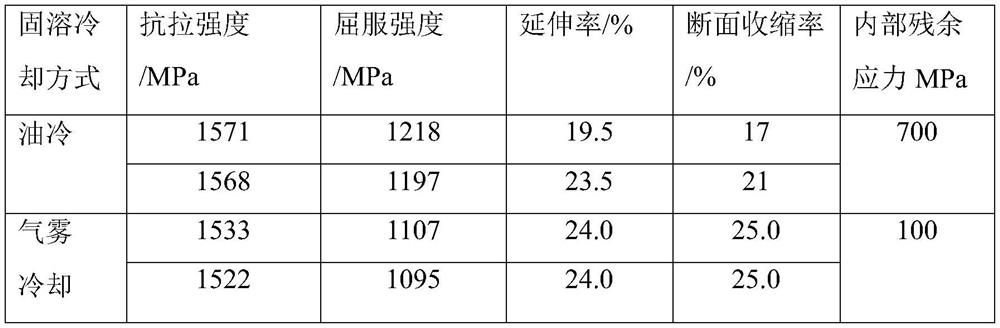

[0034] This embodiment provides a method for reducing the internal residual stress of the GH4096 alloy thin-walled disk ring, using the above-mentioned device, and the method includes:

[0035] The workpiece 4 is subjected to solution treatment in a heat treatment furnace, the heat treatment temperature is 1050°C-1080°C, and the holding time is 2-6 hours; the workpiece 4 is a GH4096 alloy;

[0036] Take the workpiece 4 out of the heat treatment furnace and fix it on the rotary table 3; the control panel 9 controls the fan 7 to start; The liquid is sprayed at the air inlet to cool the workpiece 4 by gas mist.

[0037] Further, the method includes: the time between taking the workpiece 4 out of the heat treatment furnace and starting the fan 7 does not exceed 90 seconds; the rotation speed of the workpiece during cooling is controlled at 10-20 rpm; when the surface temperature of the workpiece drops to 200 When the temperature is below ℃, the control panel 9 controls the fan 7 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com