Super high-speed quenching device for steel tube

A cooling device, ultra-fast technology, applied in the direction of quenching device, furnace, heat treatment equipment, etc., can solve the problems that the cooling device does not have ultra-fast cooling, can not achieve ultra-fast cooling effect, and the cooling uniformity is not uniform, etc., to achieve structural Simple, convenient installation and disassembly, and the effect of inhibiting bending deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

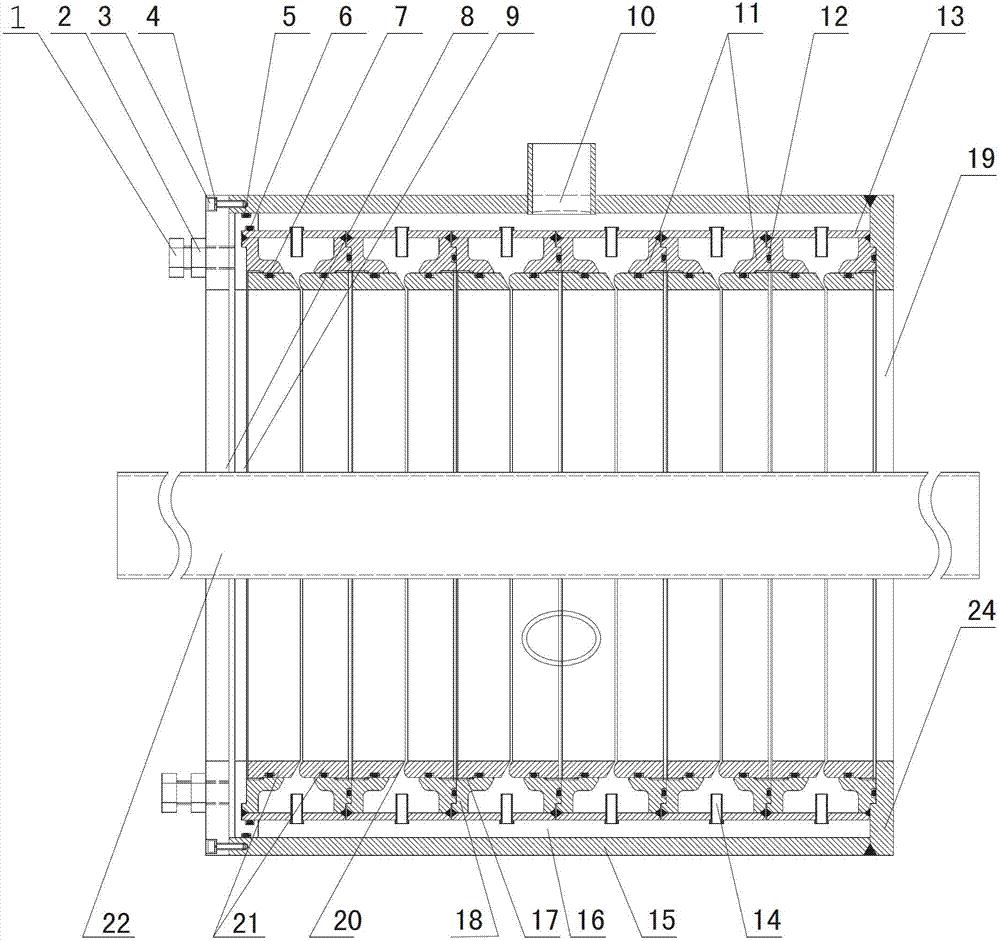

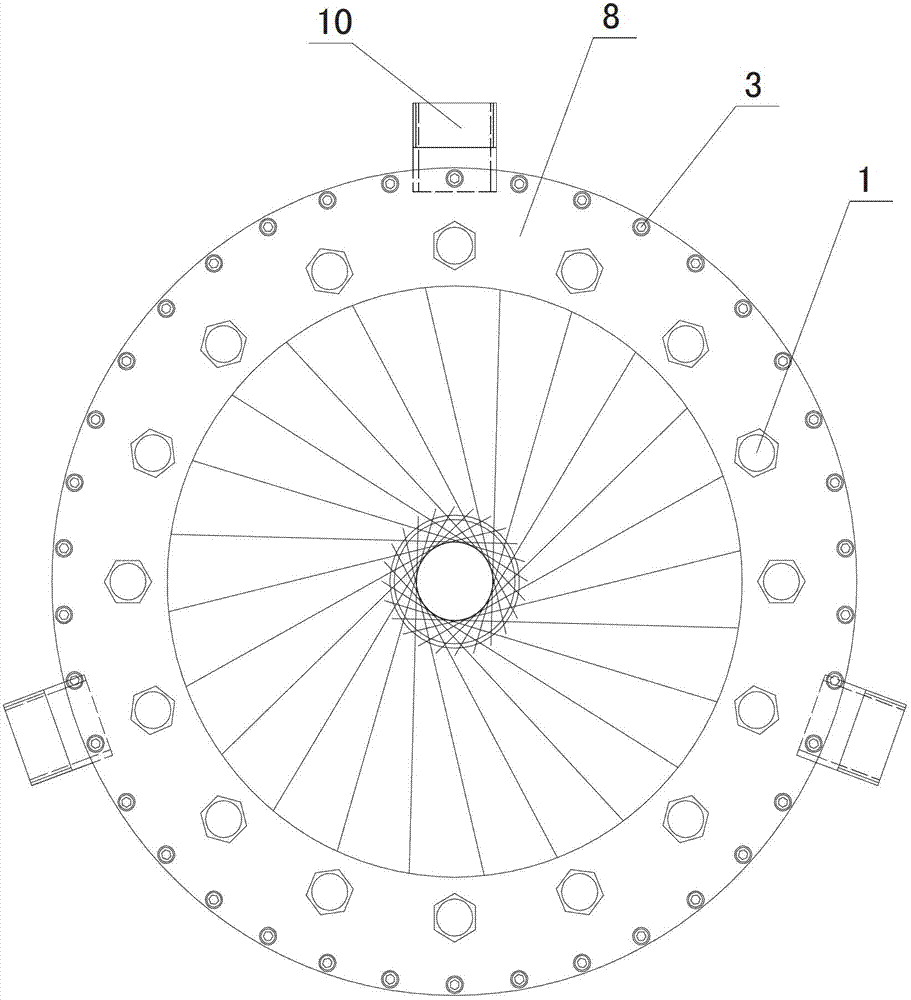

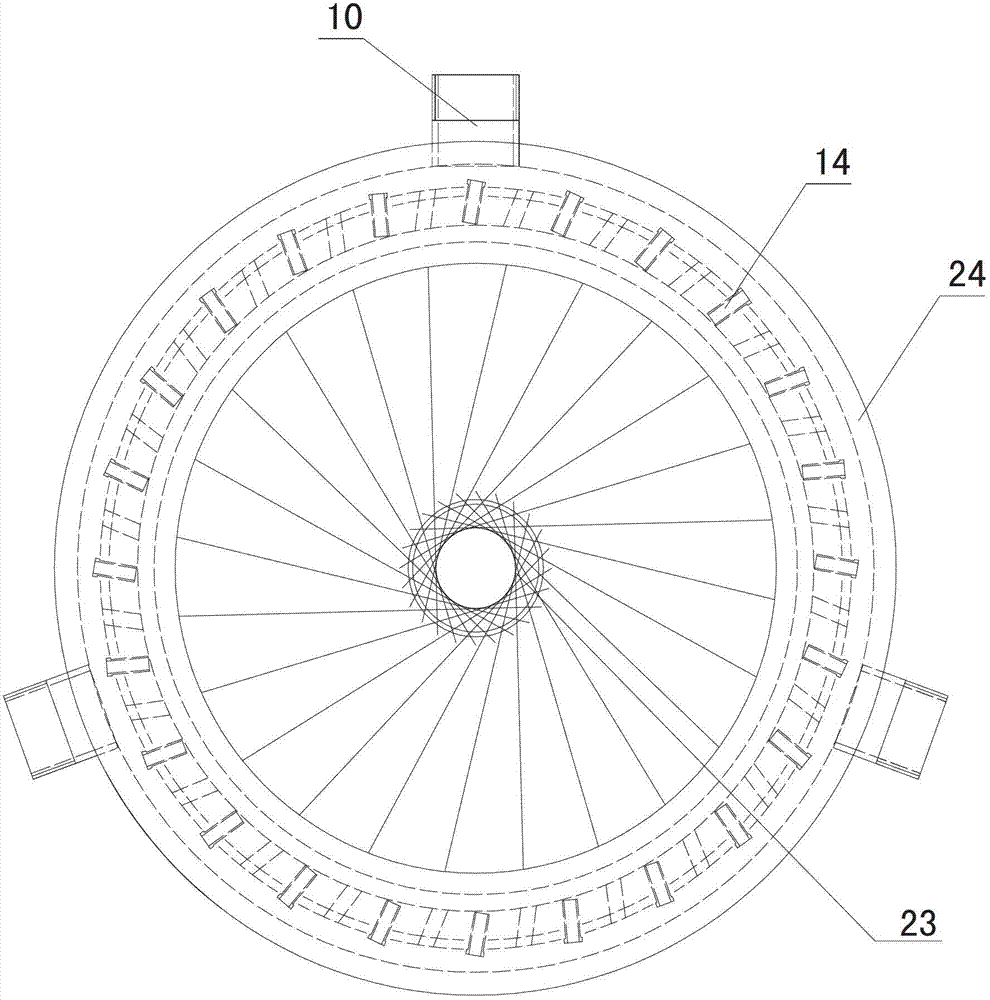

[0029] Such as Figure 1~3 As shown, a steel pipe ultra-rapid quenching cooling device is a cylindrical structure, including a casing 15 with a water inlet 10, and a number of oblique nozzle units 11 are arranged in the casing 15. The present embodiment adopts 6 slanted nozzle units 11, that is, the water flow will be sprayed from the six slanted nozzles 20, and the sprayed water flow has the same forward or backward trend as the cooling steel pipe 22 running direction, along the cooling steel pipe 22. The wall spiral jets forward or backward. The first pressing plate 8 and the second pressing plate 9 are closely pressed together with the six oblique nozzle units 11 side by side through several pressing bolts 1 and nuts 2, and the first pressing plate is pressed together through several bolts 3 and washers 4. The tight plate 8 is fixed togeth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com