Cylinder type specific cutter grinder

A pulverizer and special knife technology, which is applied in the direction of grain processing, etc., can solve the problems of uneven full-blade pulverization, large pulverization energy consumption, low output, etc., and achieve good uniform cooling effect, strong material adaptability, and large friction surface area. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

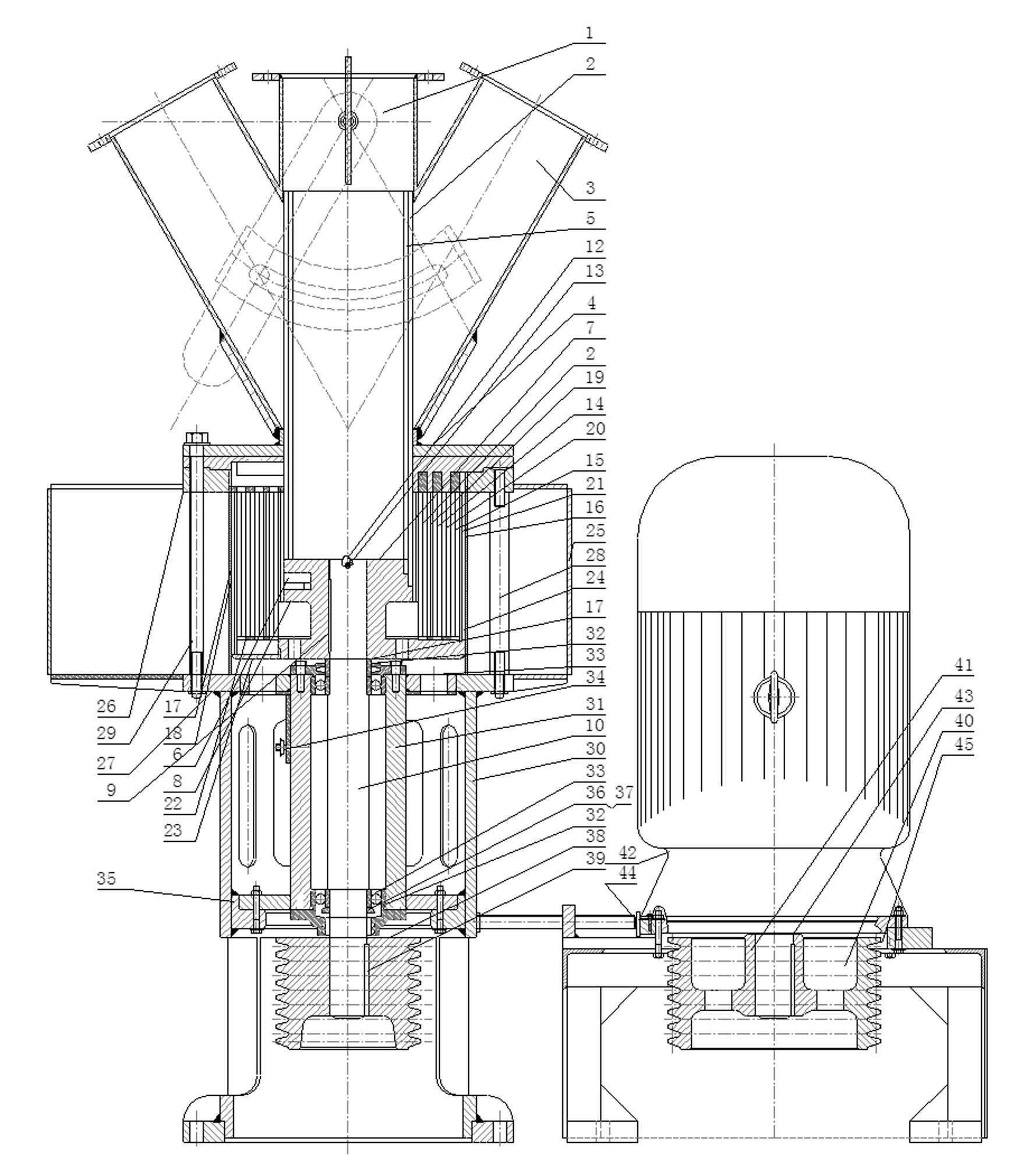

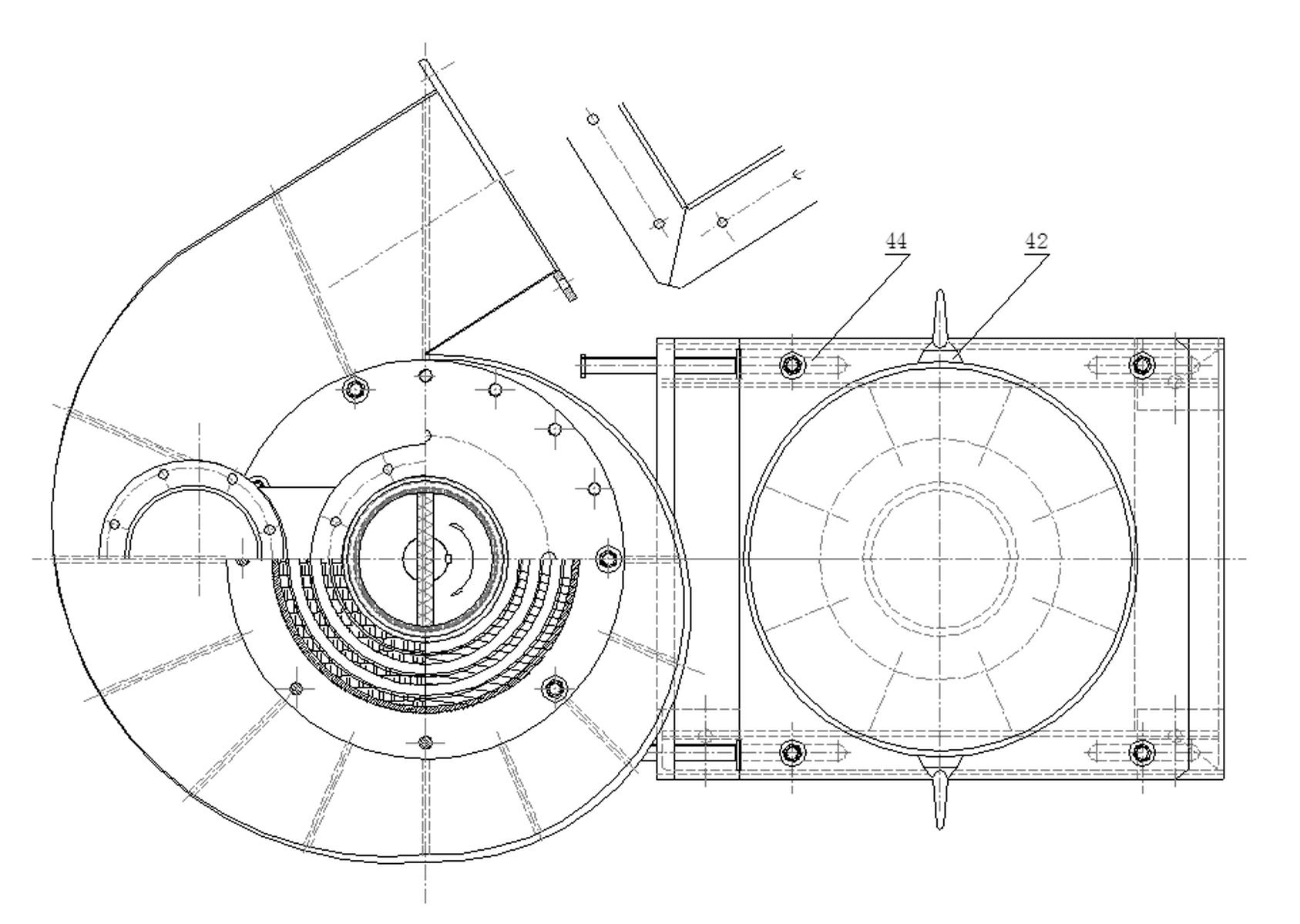

[0068] The present invention will be further elaborated below in conjunction with the accompanying drawings.

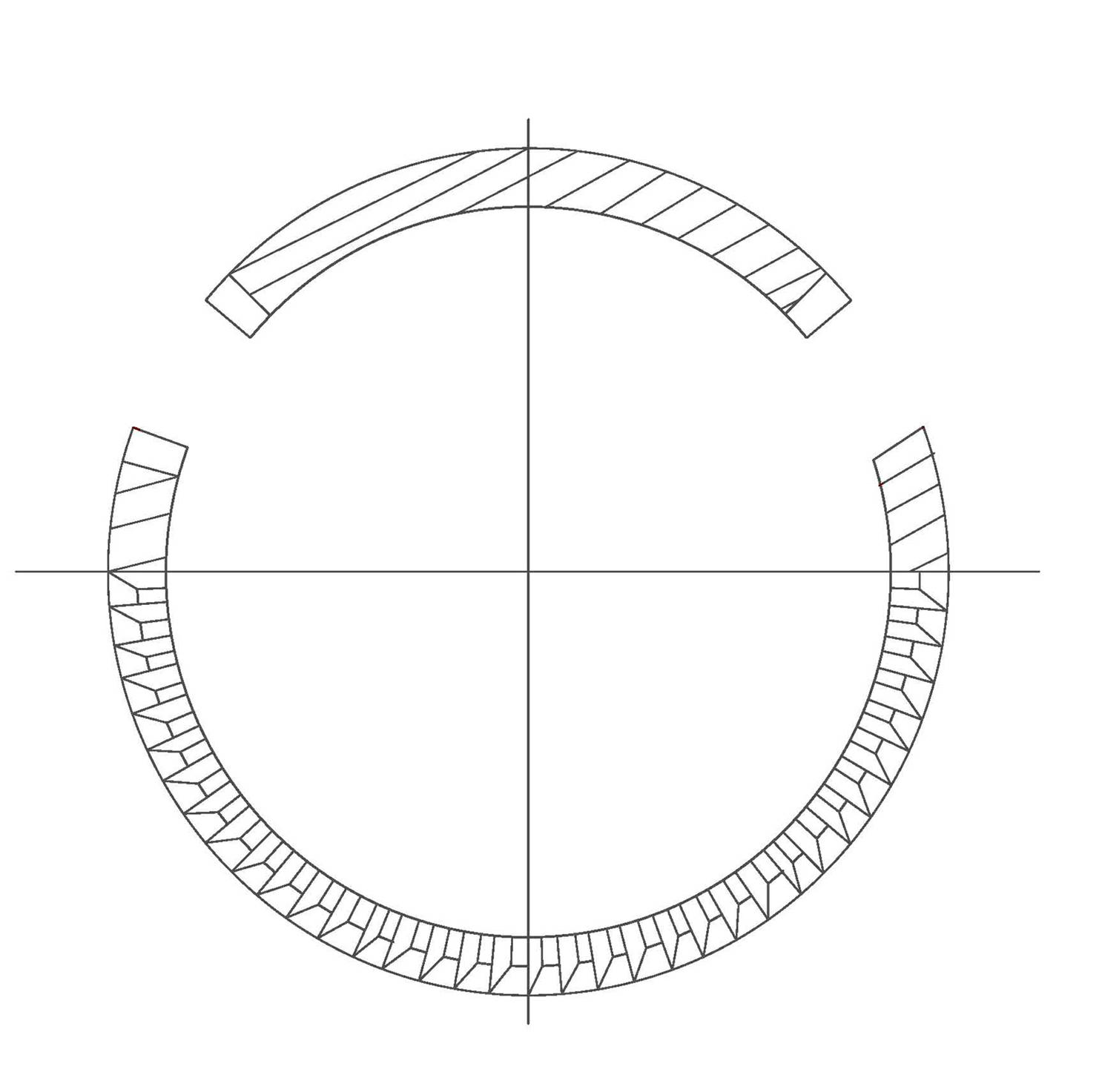

[0069] See attached figure 1 , figure 2 Shown is a preferred embodiment of the barrel-type special knife pulverizer according to the present invention: the upper air inlet butterfly valve 1 is designed to adjust the raw materials to be as dense as possible under the cold dynamic temperature of the wind-loaded material, and the flange connection seat is used in the primary crushing. Set the flange of the special knife ring 2, and then use the washer to support the seam flange 2 to ventilate, seat on the flange of the inlet 3 of the primary feed valve, and fasten it with eight M10 bolts and nuts, etc. The flange stator cutter head 4 is centered and welded together; the primary crushing special knife ring 5 is fixed on the upper plate of the rotor double cutter head 7 with three double-headed dovetail flat keys 6, in order to facilitate the installation and positioning...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com