Rotating vertical water spray quenching equipment for quenching large complicated forged components

A technology of complex forgings and water spray quenching, applied in quenching devices, heat treatment equipment, manufacturing tools, etc., can solve the problems of slowing down the cooling rate of forgings, difficulty in operation, and poor targeting of forgings, so as to improve the cooling rate and cooling. Uniformity, simple equipment operation and stable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

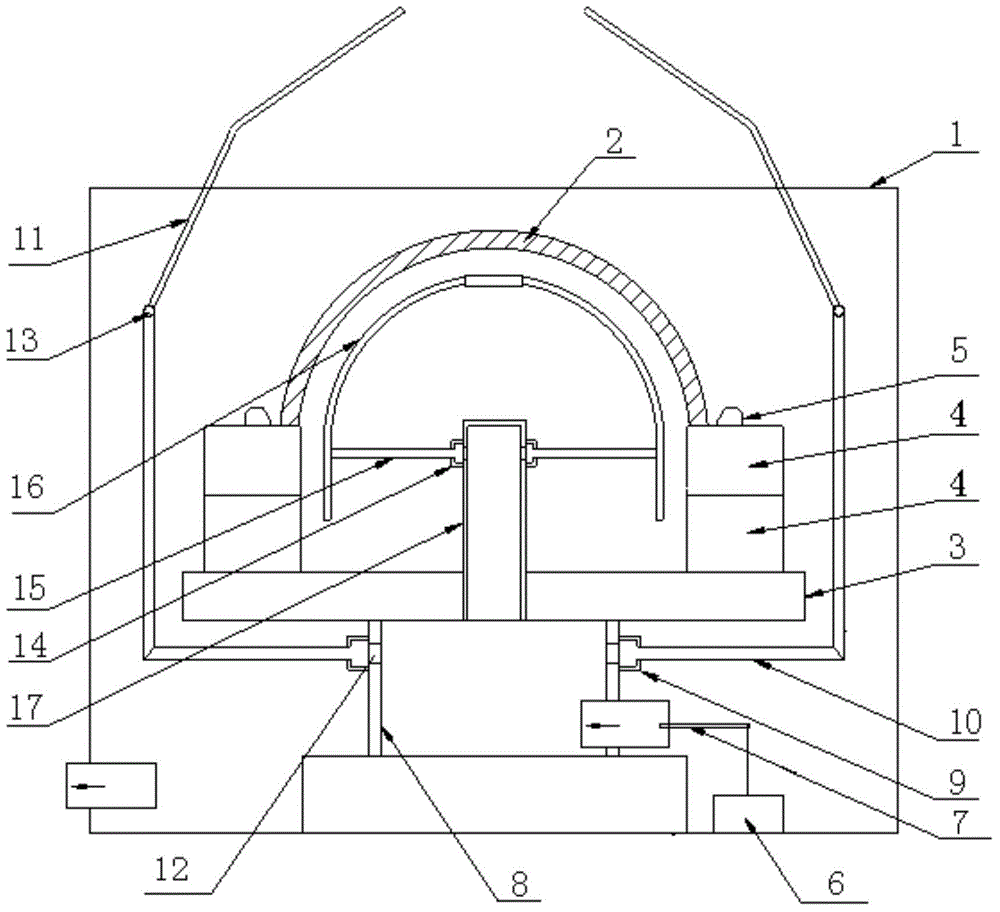

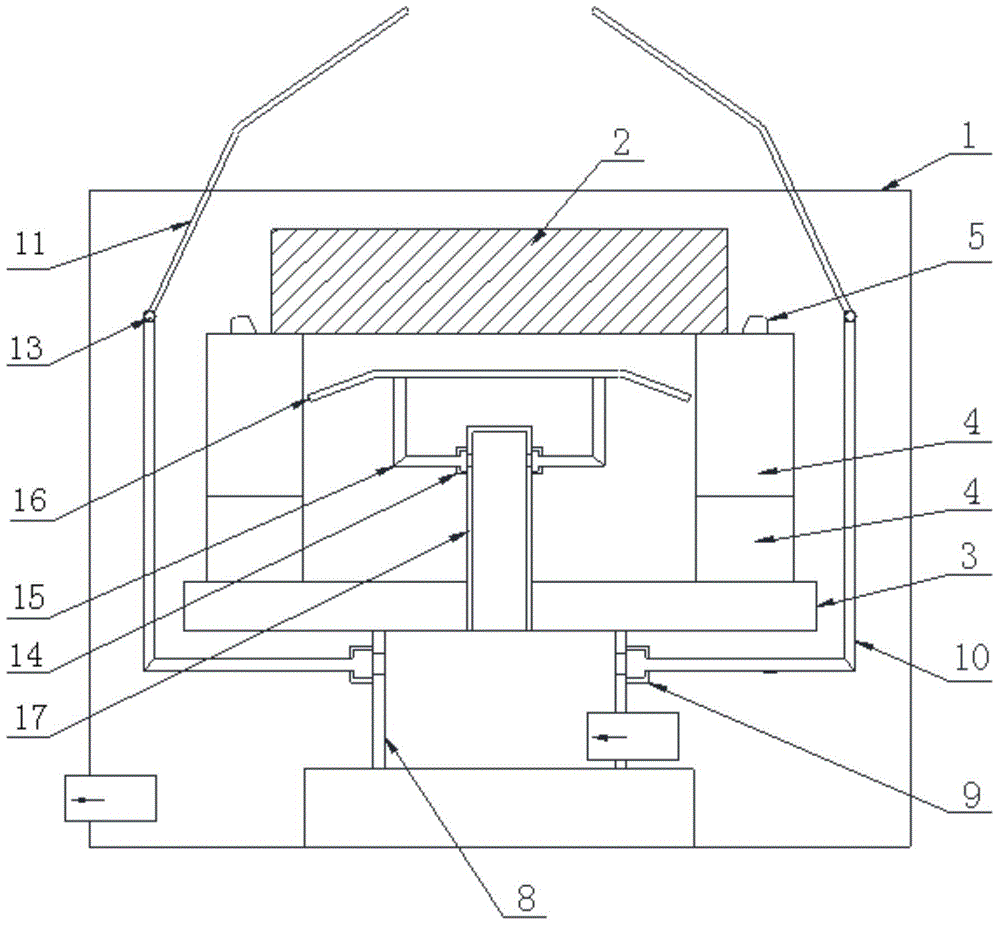

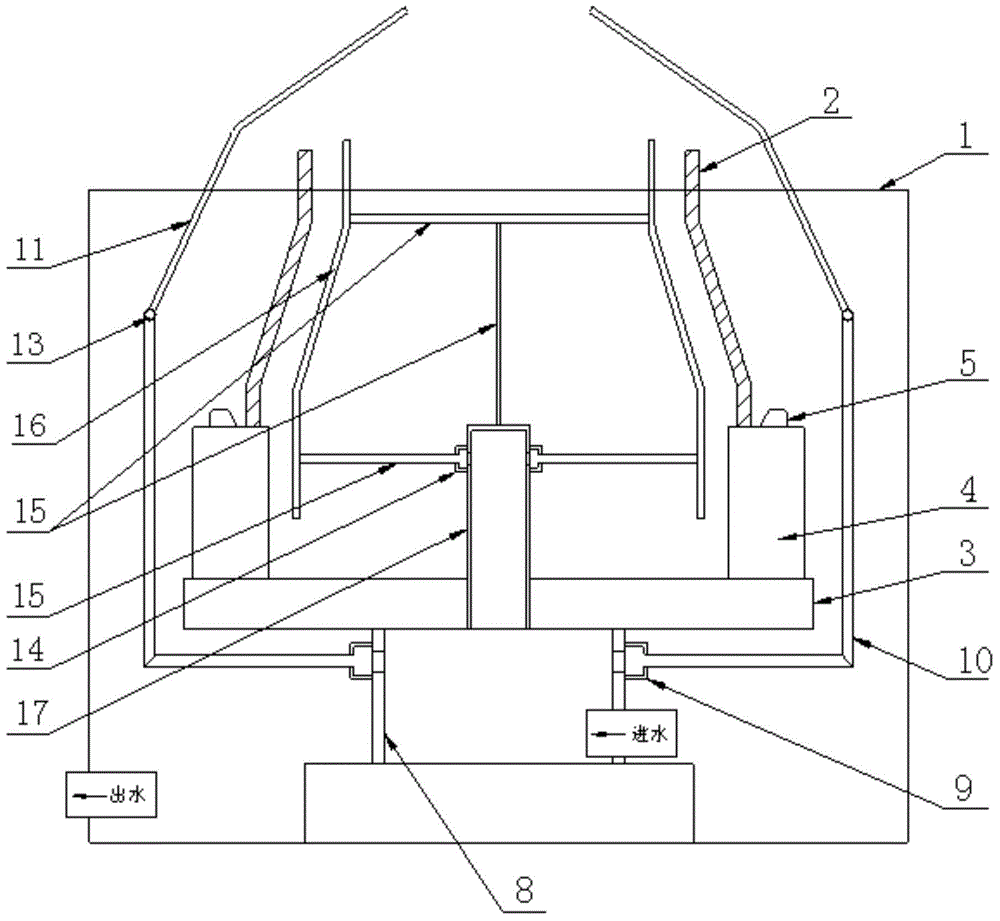

[0025] Can refer to figure 1 The shown structure understands the rotary vertical water spray quenching equipment for large complex forgings provided by the present invention, which includes several parts such as tank body 1, bearing system, inner water spray system, and outer water spray system. The water in the external reservoir is injected into the inner and outer water spray systems through the water pump through the water supply pipe, and finally flows to the inner and outer water spray pipes, and the water is sprayed to the inner and outer surfaces of the workpiece 2 through the uniformly distributed nozzles on the water spray pipes. Realize workpiece quenching and cooling. The cooling water finally collects at the bottom of the tank, is pumped out from the outlet pipe under the tank through the water pump, and then returns to the external reservoir. The entire cooling system forms a closed loop.

[0026] Specifically, the carrying system includes a workbench 3, a shim ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com