Equipment system and method for automatic cleaning and drying of braces

A technology for automatic cleaning and braces, applied in dentistry, tooth cleaning, medical science, etc., can solve problems such as lowering product quality, frequent rework, and complicated production and cleaning processes, so as to reduce internal residual stress, ensure secondary contact pollution, The effect of eliminating the risk of chemical reactions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] Below by embodiment the present invention will be further described, and its purpose is only to understand research content of the present invention better but not limit protection scope of the present invention.

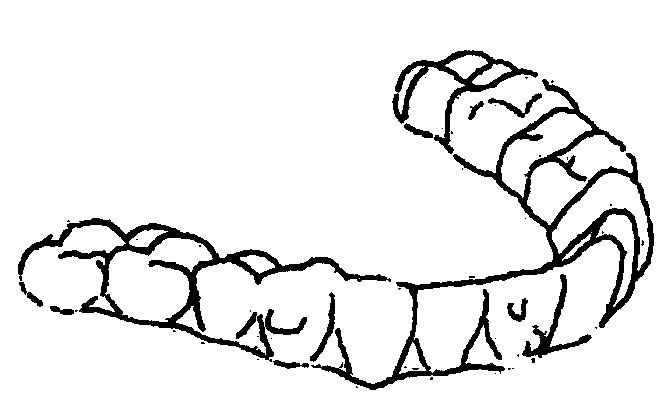

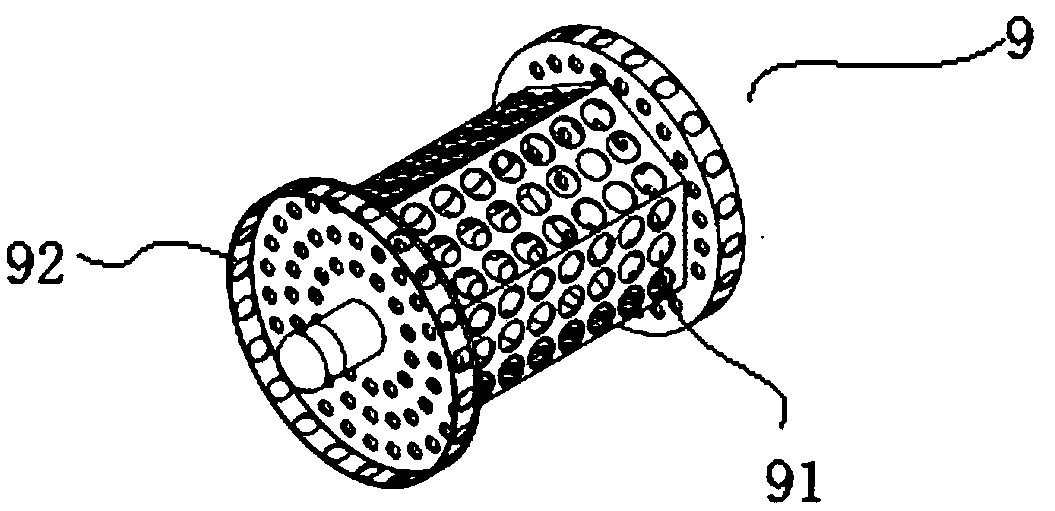

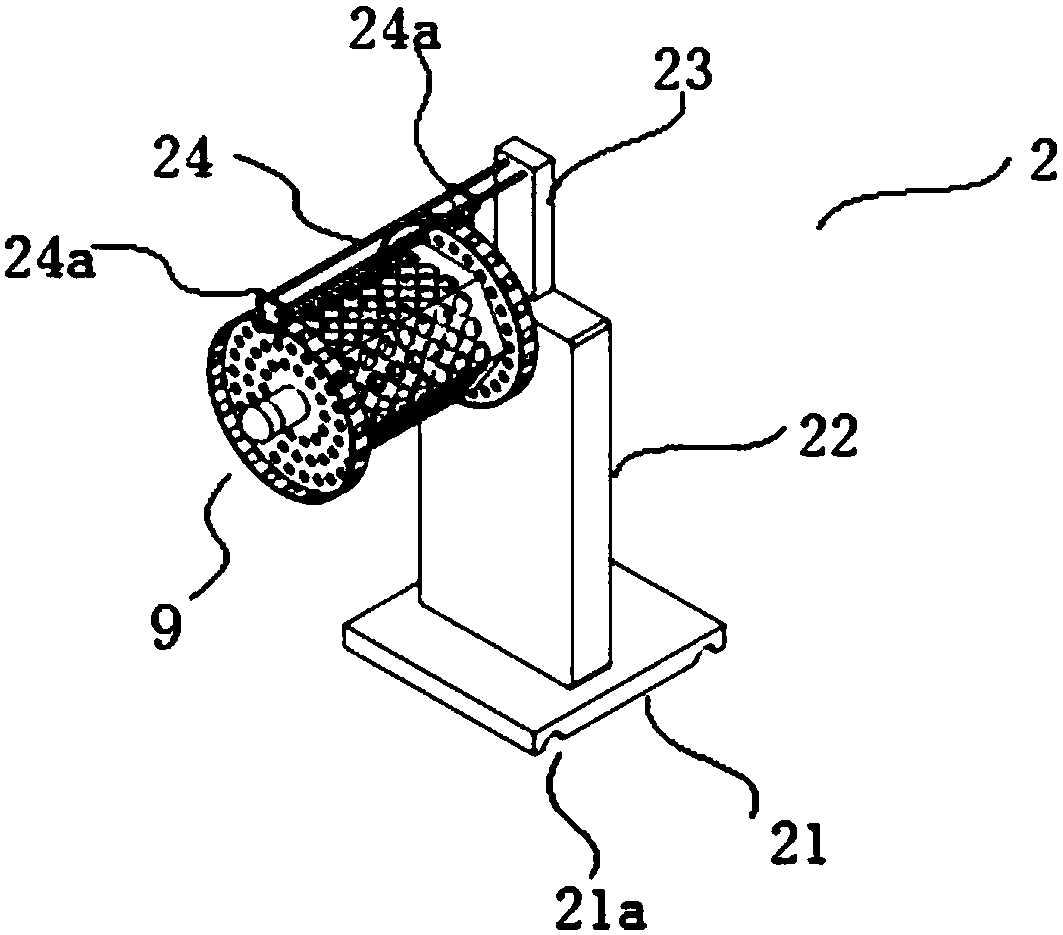

[0048] One embodiment of the present invention proposes an equipment system for automatic cleaning and drying of dental crowns, where dental crowns can be invisible dental crowns, MRC dental crowns, polymer material dental crowns or other intraoral functional devices. Such as Figure 5 and 6 As shown, the equipment system exists in an assembly line and integrates multiple functions to meet the requirements for automatic cleaning, drying and sterilization of dental braces. The equipment system as a whole includes: an automatic feeding table 1, which is used to transport the tooling basket 9 containing the braces to be cleaned to a designated position, and the tooling basket 9 is provided with identification information for collecting and tracking braces infor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com