Additive for improving wear resistance of iron casting

A pig iron casting and wear resistance technology, which is applied in the field of additives for improving the wear resistance of pig iron castings, can solve the problem that the performance of pig iron materials cannot meet the needs of the market, and achieves enhanced wear resistance, reduced residual stress, improved service life and safety effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

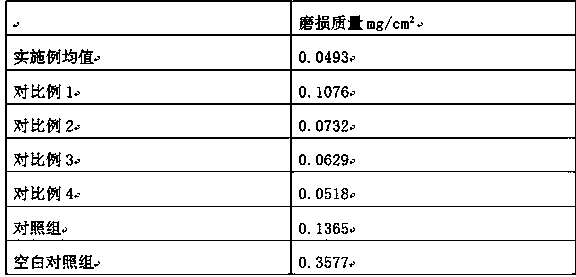

Examples

Embodiment 1

[0020] An additive for improving the wear resistance of pig iron castings is made of the following components in parts by weight: humic acid modified graphene 6, cryolite 4, sodium alginate 1.5, and ferromolybdenum 0.55.

[0021] Further, the preparation method of the humic acid modified graphene is:

[0022] (1) The graphene is uniformly dispersed in the ethanol solution at a ratio of 30g:300mL, and then treated with ultrasound for 2 minutes to obtain a graphenol suspension;

[0023] (2) Add 1.6% of the graphene mass of triethanolamine to the graphene alcohol suspension, heat to 72°C, and stir at 3500r / min for 40 minutes to obtain the graphene suspension intermediate;

[0024] (3) Add 5-8% humic acid and 0.5% trimellitic acid to the graphene suspension intermediate, and stir for 2 hours at 300r / min under the heating of a water bath at 80℃, and then proceed Suction filtration to obtain the modified graphene initial material. Put the modified graphene initial material into a reaction c...

Embodiment 2

[0033] An additive for improving the wear resistance of pig iron castings is made of the following components in parts by weight: humic acid modified graphene 9, cryolite 6, sodium alginate 1.9, and ferromolybdenum 0.59.

[0034] Further, the preparation method of the humic acid modified graphene is:

[0035] (1) The graphene is uniformly dispersed in the ethanol solution at a ratio of 30g:300mL, and then treated with ultrasound for 2 minutes to obtain a graphene alcohol suspension;

[0036] (2) Add 1.6% of the graphene mass of triethanolamine to the graphene alcohol suspension, heat to 72°C, and stir at 3500r / min for 40 minutes to obtain the graphene suspension intermediate;

[0037] (3) Add 5-8% humic acid and 0.5% trimellitic acid to the graphene suspension intermediate, and stir for 2 hours at 300r / min under the heating of a water bath at 80℃, and then proceed Suction filtration to obtain the modified graphene initial material. Put the modified graphene initial material into a rea...

Embodiment 3

[0046] An additive for improving the wear resistance of pig iron castings is made of the following components in parts by weight: humic acid modified graphene 7, cryolite 5, sodium alginate 1.6, and ferromolybdenum 0.58.

[0047] Further, the preparation method of the humic acid modified graphene is:

[0048] (1) The graphene is uniformly dispersed in the ethanol solution at a ratio of 30g:300mL, and then treated with ultrasound for 2 minutes to obtain a graphene alcohol suspension;

[0049] (2) Add 1.6% of the graphene mass of triethanolamine to the graphene alcohol suspension, heat to 72°C, and stir at 3500r / min for 40 minutes to obtain the graphene suspension intermediate;

[0050] (3) Add 5-8% humic acid and 0.5% trimellitic acid to the graphene suspension intermediate, and stir for 2 hours at 300r / min under the heating of a water bath at 80℃, and then proceed Suction filtration to obtain the modified graphene initial material. Put the modified graphene initial material into a rea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com