Plate shape control method of online-quenched high-strength steel plate

A high-strength steel plate and shape control technology, applied in temperature control, rolling mill control device, heat treatment process control, etc., can solve problems such as increased bending degree, reduced yield, and large shape defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

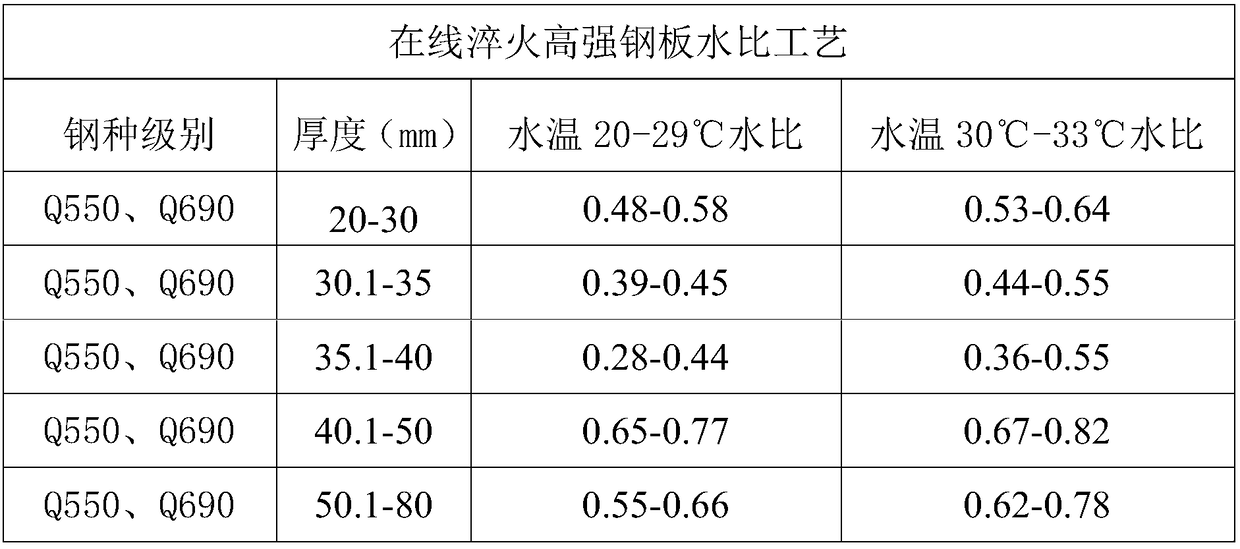

[0064] The steel type of the high-strength steel plate in this embodiment is Q690D, and the thickness of the finished product is 40mm.

[0065] The main chemical composition of the high-strength steel plate in this example is by weight percentage: C: 0.15%, Si: 0.26%, Mn: 1.45%, P: 0.010%, S: 0.006%, Ni: 0.25%, Cr: 0.32% , Nb: 0.03%, V: 0.04%, Ti: 0.025%, Mo: 0.31%, B: 0.0015%, and the balance is Fe and unavoidable impurities.

[0066] Including the following steps:

[0067] 1. Heating: Heat the continuous casting slab in a heating furnace, the heating temperature is 1220°C, the heating rate is 9min / cm, and the temperature of the continuous casting slab is 1215°C.

[0068] 2. Descaling: Use the pre-descaler system to descale the heated continuous casting slab with high-pressure water, and the pressure of the high-pressure water is 25Mpa.

[0069] 3. Rolling: use double stands, roll in the two-phase area of austenite recrystallization zone and austenite non-recrystallizatio...

Embodiment 2

[0075] The steel grade of the high-strength steel plate in this embodiment is Q690D, and the thickness of the finished product is 25 mm.

[0076] The main chemical components of the high-strength steel plate in this example are: C: 0.15%, Si: 0.21%, Mn: 1.25%, P: 0.010%, S: 0.006%, Cr: 0.24%, Nb: 0.028% , Ti: 0.023%, Mo: 0.26%, B: 0.0013%, and the balance is Fe and unavoidable impurities.

[0077] Including the following steps:

[0078] 1. Heating: Heat the continuous casting slab in a heating furnace, the heating temperature is 1220°C, the heating speed is 8min / cm, and the temperature of the continuous casting slab is 1220°C.

[0079] 2. Descaling: Use the pre-descaler system to descale the heated continuous casting slab with high-pressure water, and the pressure of the high-pressure water is 24.5Mpa.

[0080]3. Rolling: use double stands, roll in the two-phase area of austenite recrystallization zone and austenite non-recrystallization zone, when rolling in the austenite...

Embodiment 3

[0086] The steel type of the high-strength steel plate in this embodiment is 550Mpa, and the thickness of the finished product is 60mm.

[0087] The main chemical composition of the high-strength steel plate in this example is by weight percentage: C: 0.13%, Si: 0.22%, Mn: 1.28%, P: 0.010%, S: 0.006%, Cr: 0.24%, Nb: 0.024% , Ti: 0.015%, Mo: 0.23%, B: 0.0012%, and the balance is Fe and unavoidable impurities.

[0088] Including the following steps:

[0089] 1. Heating: Heat the continuous casting slab in a heating furnace, the heating temperature is 1230°C, the heating rate is 9min / cm, and the temperature of the continuous casting slab is 1225°C.

[0090] 2. Descaling: Use the pre-descaler system to descale the heated continuous casting slab with high-pressure water, and the pressure of the high-pressure water is 25.5Mpa.

[0091] 3. Rolling: use double stands, roll in the two-phase area of austenite recrystallization zone and austenite non-recrystallization zone, when roll...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Unevenness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com