Vinyl ester resin heavy mortar floor

A vinyl ester resin and floor technology, which is used in buildings, building structures, floors, etc., can solve the problems of reducing resin mortar, unable to meet the application requirements of heavy industrial production workshops, etc., and achieves reduced curing heat release and soft structure. , the effect of low fever

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

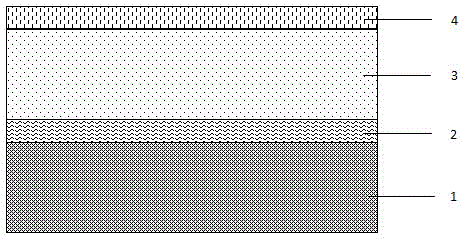

[0014] refer to figure 1 , which is the structure of vinyl ester resin heavy mortar floor, wherein: 1 is the base layer; 2 is the primer layer; 3 is the vinyl ester resin mortar layer; 4 is the top coat layer.

[0015] Above-mentioned vinyl ester resin mortar layer can adopt the raw material formula of following parts by weight to make:

[0016] Formula 1: Mix 120 parts of vinyl ester resin, 3 parts of methyl ethyl ketone peroxide, 1.5 parts of cumene hydroperoxide, and 2 parts of cobalt isooctanoate into 1000 parts of quartz sand aggregate.

[0017] Formula 2: Mix 100 parts of vinyl ester resin, 2 parts of methyl ethyl ketone peroxide, 1 part of cumene hydroperoxide, and 1 part of cobalt isooctanoate into 1200 parts of quartz sand aggregate.

[0018] Formula 3: The vinyl ester resin mortar layer is made of the following raw materials in parts by weight: 110 parts of vinyl ester resin, 2.5 parts of methyl ethyl ketone peroxide, 1.3 parts of iso Propylbenzene hydroperoxide, 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com