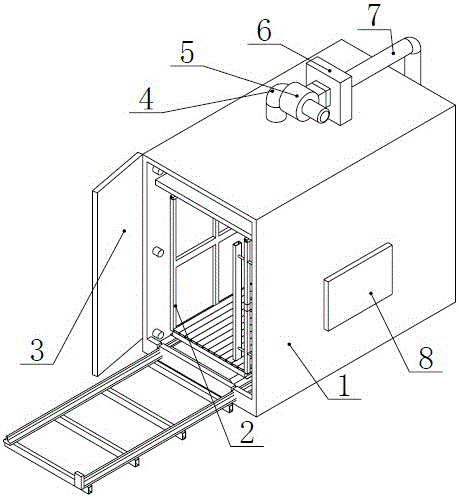

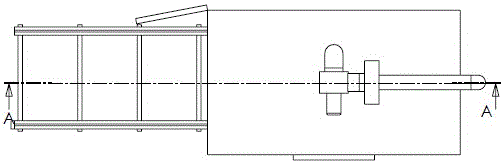

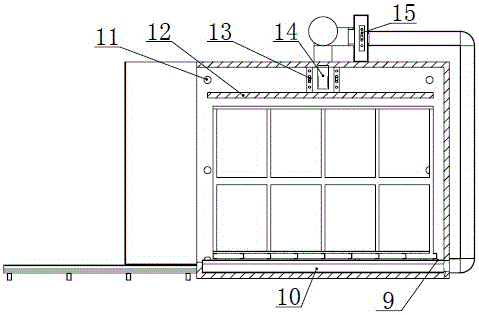

An ecological board oven and its operating method

An ecological board and oven technology, which is applied to the operation of ecological board ovens and the field of ecological board ovens, can solve the problem of uneven internal water content due to residual stress, reduce the service life of ecological boards, and cannot remove internal stress, etc. The problem is that the baking method is simple and convenient, the service life is improved, and the internal water content is uniform.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Embodiment 1: An operating method of an ecological board baking oven, comprising the following steps: moving the bracket out of the box, placing the ecological board to be baked on the bracket, and fixing the ecological board by a locking mechanism after loading is completed, Push it into the box, close the oven door, turn on the heating equipment for heating, the temperature rises, and bake at a constant temperature after reaching the set temperature of 200~300 degrees. After baking for 30 minutes, open the oven door and remove the bracket , for cooling, cooling to below 30 degrees for unloading, and the next round of baking after unloading.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com