Technological parameter optimization method for eliminating residual stress of ring part through cold rolling method

A technology of process parameter optimization and residual stress, applied in multi-objective optimization, design optimization/simulation, metal rolling, etc., can solve the problem of single evaluation of residual stress effect, failure to reflect the effect of stress relief, single evaluation of residual stress relief effect of rings And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0068]In this embodiment, a 2219 aluminum alloy rectangular ring is selected as the experimental object.

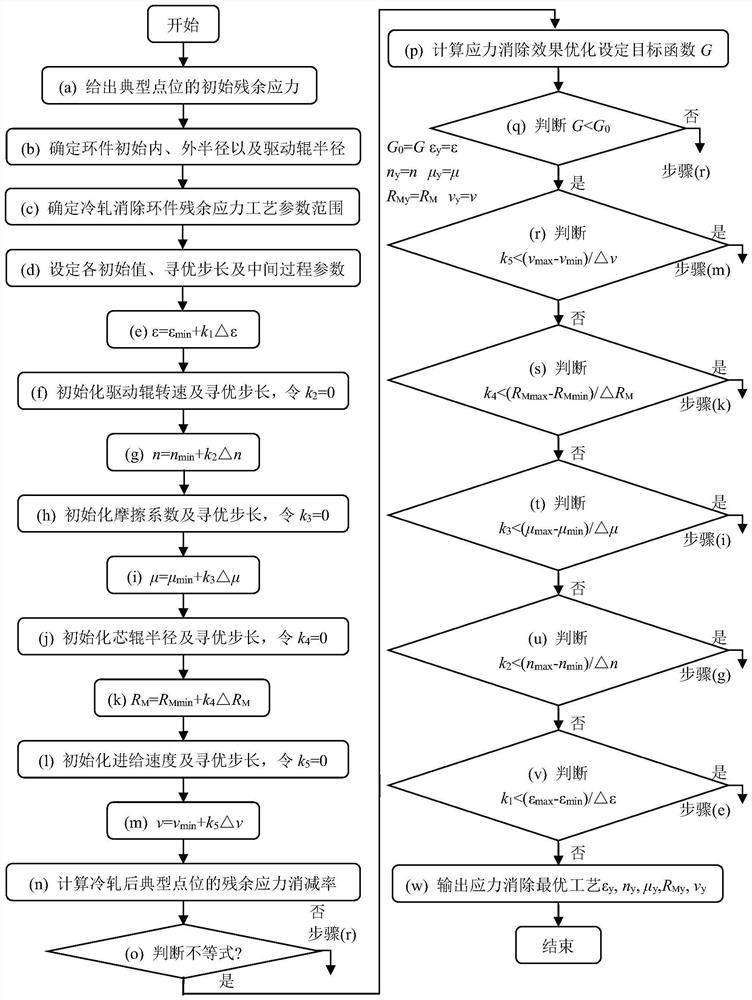

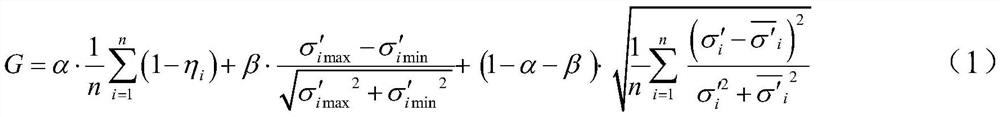

[0069]A method for optimizing process parameters of the cold rolling method to eliminate residual stress of the ring, which is characterized in that it includes the following steps (the general flow chart is as follows:figure 1 Shown):

[0070](a) Select 100 typical points on the ring and give the initial residual stress σ at the same timei(i=1,2,3...,100);

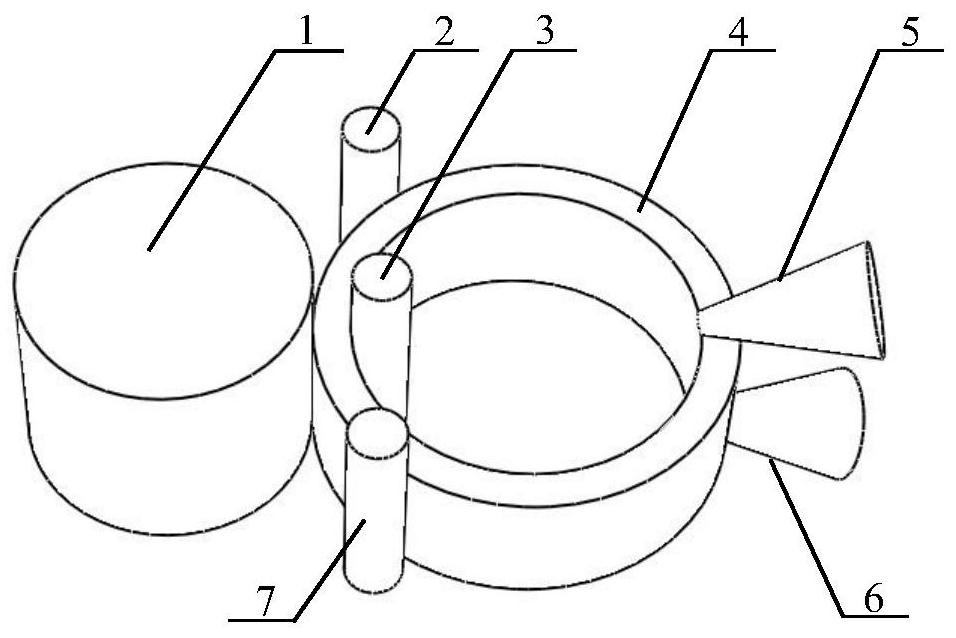

[0071](b) Determine the initial outer radius R of the ring0=250mm and inner radius r0=200mm and driving roller radius RD=1000mm;

[0072](c) Based on the ring rolling mechanics and kinematics conditions, combined with the requirements of the final size and mechanical properties of the ring, and at the same time considering the capacity of the ring rolling process and equipment, collect and determine the cold rolling method to eliminate the residual stress of the ring. The process parameters are mainly Including: maximum reduction rate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com