Thin wall low-pressure injection molding secondary forming mechanism

A technology of secondary molding and low pressure injection molding, which is applied to flat products, household appliances, other household appliances, etc., can solve the problems of unstable product size, low product qualification rate, high pre-deformation risk, etc. The effect of small product deformation and large process adjustment range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

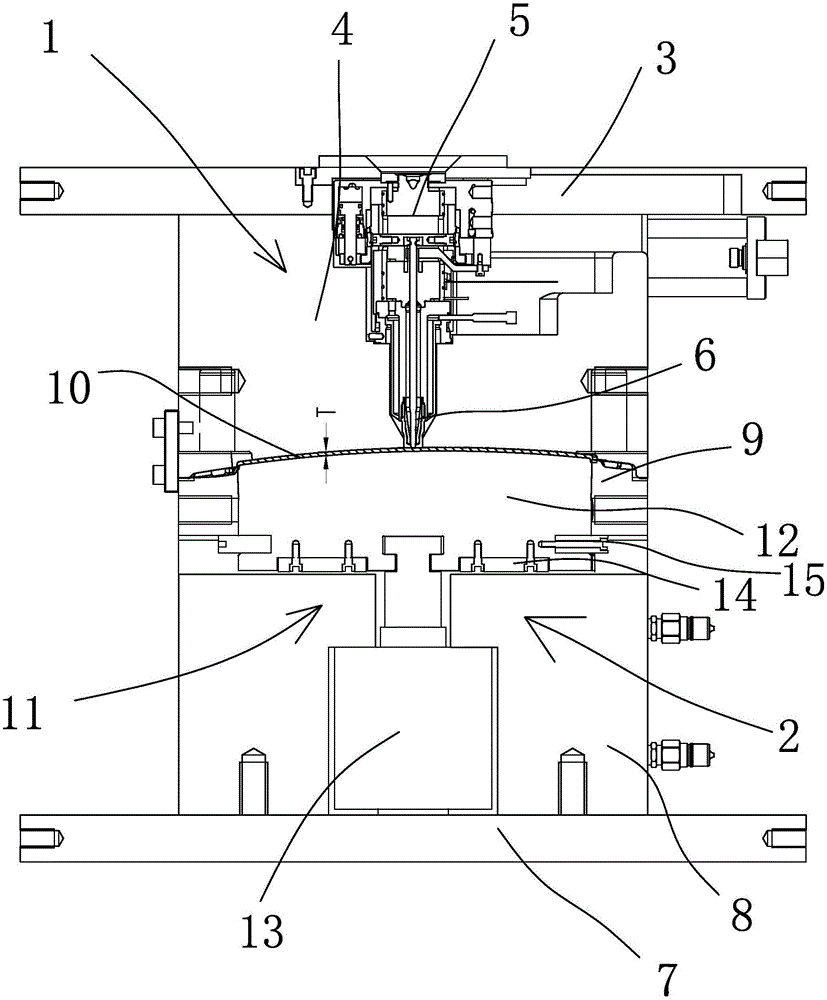

[0011] In the figure, the front mold assembly 1; the lower mold assembly 2; the upper fixing plate 3; the mother template 4; the hot runner 5; the valve needle 6; the lower fixing plate 7; the support block 8; Forming device 11; top block 12; oil cylinder 13; balance block 14; limit block 15.

[0012] Such as figure 1 As shown, the secondary molding mechanism for thin-walled low-pressure injection molding includes a front mold assembly 1 and a lower mold assembly 2. The front mold assembly 1 includes an upper fixing plate 3, a mother template 4 and a hot runner 5. The front end is provided with a valve needle 6, the female template 4 is fixed on the upper fixing plate 3, the hot runner 5 is arranged in the female mold, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com