Piezoelectric dynamic plasticizing forming device and injection molding method thereof

A molding device and dynamic technology, applied in the field of plasticizing molding devices, can solve the problems of inability to achieve sub-ultrasonic vibration frequency, driving frequency, adjustment of applied voltage driving waveform, inability to achieve amplitude, etc., to promote orientation and stretching, and avoid shrinkage. Empty, ordered effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1)

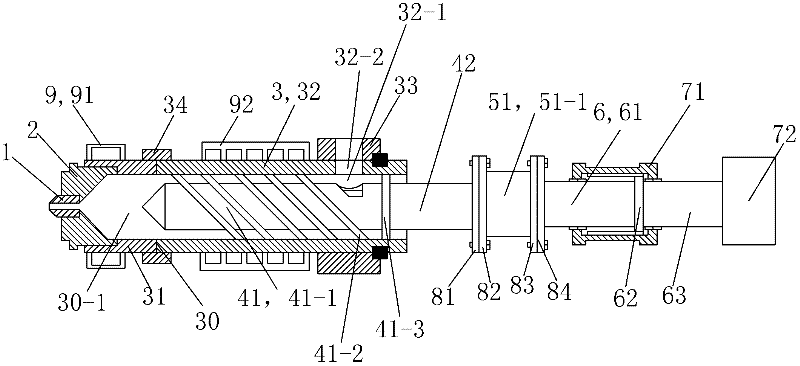

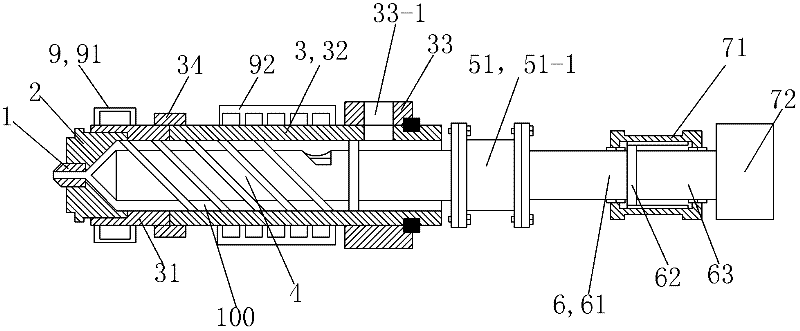

[0046] See figure 1 , The piezoelectric dynamic plasticizing molding device of this embodiment includes a frame, a nozzle 1, a nozzle seat 2, a material tube 3, a compression screw 4, a piezoelectric ceramic actuator 51, a piston rod 6, a hydraulic cylinder 71, and a hydraulic motor 72 and heating jacket9. The nozzle 1, the nozzle seat 2 and the barrel 3 are coaxially arranged and connected in sequence from front to back and from inside to outside. Hydraulic cylinder 71 is fixed on the frame by its cylinder body, and hydraulic cylinder 71 and hydraulic motor 72 are all provided with the interface that links to each other with hydraulic pump when using.

[0047] The rack (not shown) sits and is secured to the ground. The feed pipe 3 is composed of a feed pipe head 31, a feed pipe main body 32, a feeding trough 33 and a connecting sleeve 34; the feed pipe 3 is installed on the frame by its feed pipe main body 32. The material pipe head 31 is a cylindrical steel integral part ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com