Aromatic group-containing amine oxide type ampholytic surfactant, and preparation method and application thereof

A surfactant and amine oxide technology, applied in chemical instruments and methods, drilling compositions, chemical/physical processes, etc., can solve the problems of high production cost, low high temperature resistance, etc., and improve compatibility. , improve viscoelasticity, improve the effect of interface activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

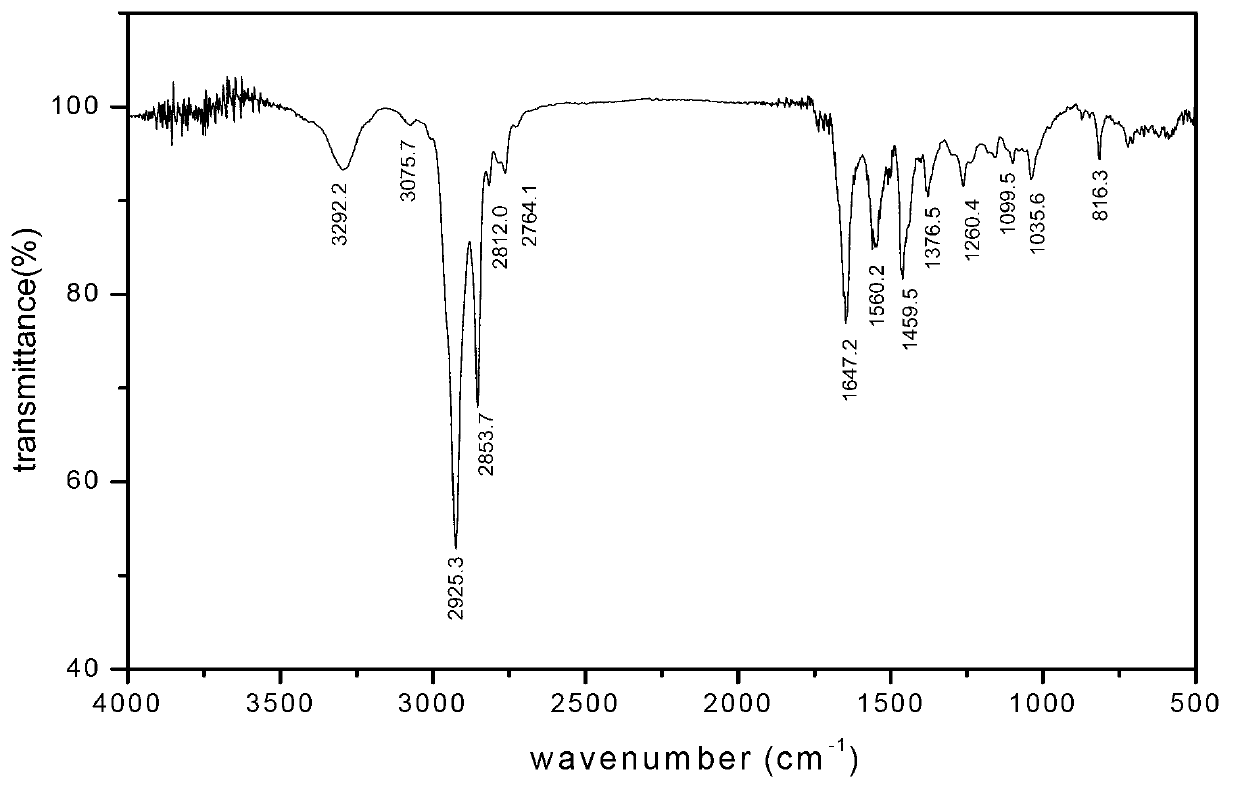

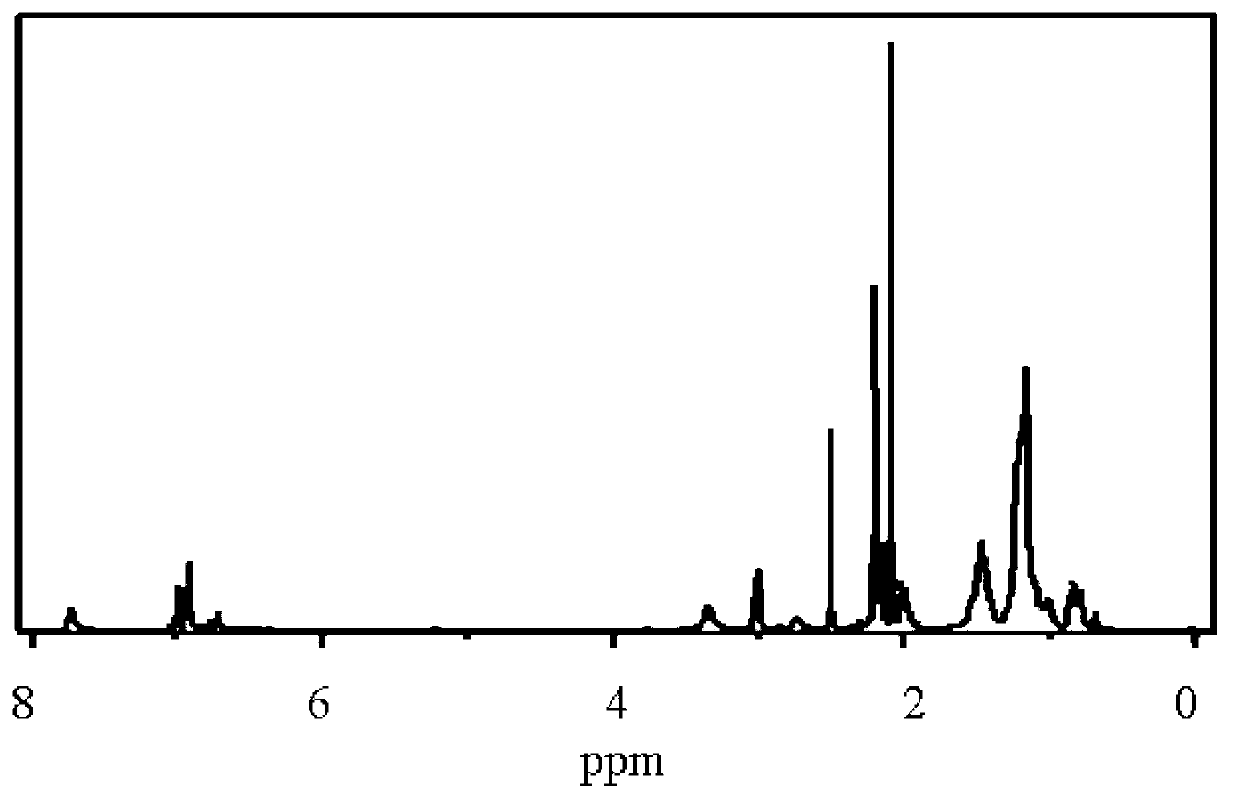

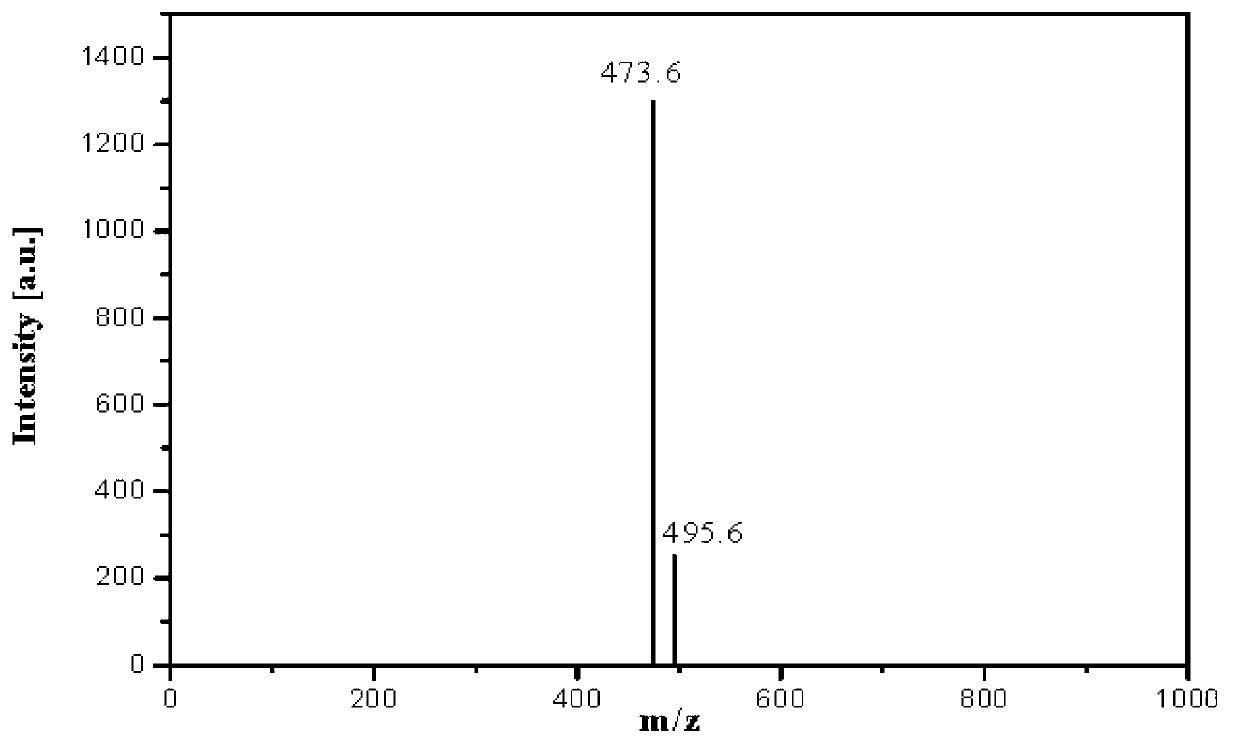

[0047] This embodiment provides an amine oxide amphoteric surfactant containing an aromatic group, the structure of which is shown in formula 4,

[0048]

[0049] The synthetic route of this amine oxide amphoteric surfactant containing aromatic group is as follows:

[0050]

[0051] The preparation method of the amine oxide amphoteric surfactant containing aromatic groups comprises the following steps:

[0052] (1) Fowler's Alkylation: In a sealed reactor, add 2.5mol m-xylene and 1.5mol protonic acid catalyst, then raise the temperature to 120°C, add 1mol methyl oleate dropwise for 6 hours, drop After the addition was completed, react for 3 hours to obtain a crude product mixture of m-xylene oleate; at room temperature, allow the crude product mixture of m-xylene oleate to stand for stratification, and add ice water dropwise thereto Rinse three times (the amount of each ice water rinse is the same as the volume of the protonic acid catalyst), separate the aqueous soluti...

Embodiment 2

[0064] This example provides the evaluation of the interfacial properties and rheological properties of the amine oxide amphoteric surfactant containing aromatic groups in Example 1, and the composite surface activity of the amine oxide amphoteric surfactant and low tension surfactant. Evaluation of the interface properties and rheological properties of the agent.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com