Plastic-wooden composite profile conditioning chamber

A composite profile and health room technology, applied in the field of wood-plastic composite profile health room, can solve problems such as shrinkage and engineering defects, and achieve the effects of wide application range, high dimensional stability and convenient use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

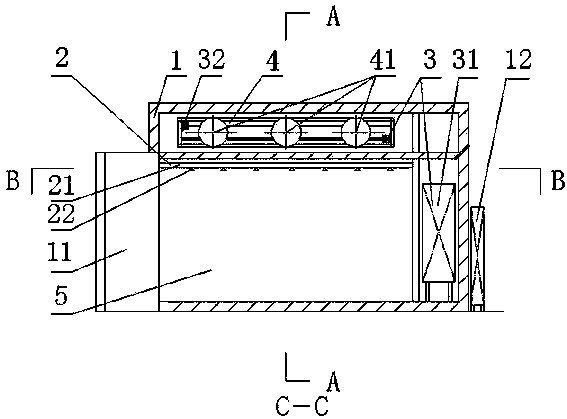

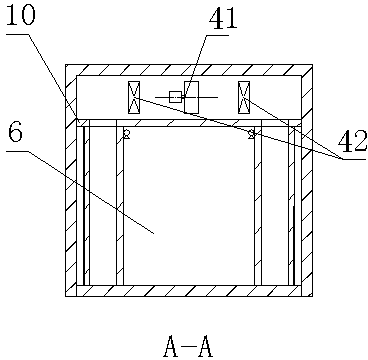

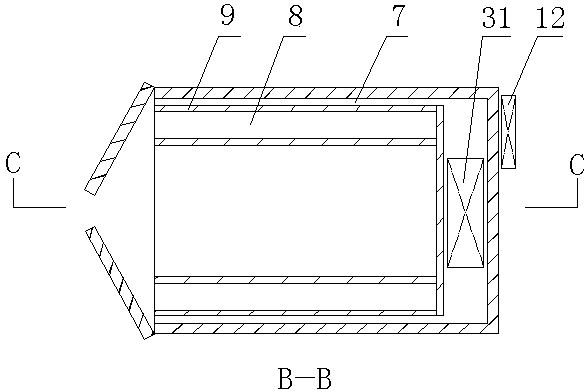

[0019] Such as Figure 1~3 As shown, a wood-plastic composite profile health room includes a health room 1, a humidity control device 2, a heating device 3, and a ventilation device 4. The front part of the health care room 1 is provided with a compartment 5 for accommodating wood-plastic composite profiles. The front side wall of the compartment 5 is provided with an entrance and exit 6, and the left and right sides of the compartment 5 are provided with a humidity control device 2, and the heating device 3 includes a microwave generator 31 and a steam heater 32. The microwave generator 31 is arranged at the rear of the health preservation room 1 , and the steam heater 32 is arranged at the top of the health preservation room 1 together with the ventilation device 4 .

[0020] In this embodiment, the left and right side walls of the health care room 1 are respectively provided with a microwave transmission channel 7, and the microwave transmission channel 7 is connected with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com