Preparation method of ultrahigh-strength 7-series aluminum sheet

An ultra-high-strength, thin-plate technology, which is applied in the direction of improving process efficiency, can solve problems not involved in the processing method of cold-rolled thin strips, and achieve the effects of ensuring strength, reducing residual stress, and improving the tendency of edge cracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

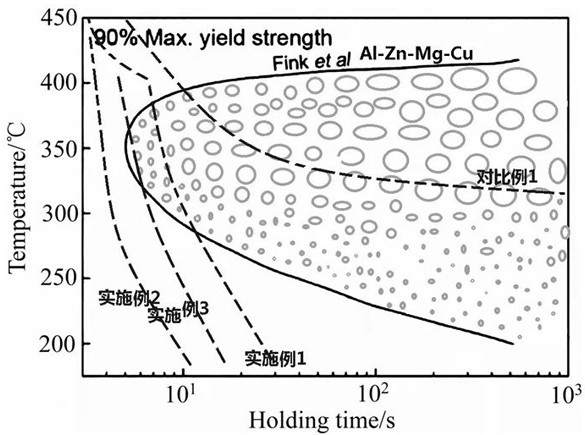

Embodiment 1

[0042]A method for preparing an ultra-high-strength 7-series aluminum sheet, wherein the chemical composition of the aluminum alloy sheet and strip is calculated by mass fraction: Si0.06%, Fe0.23%, Cu1.1%, Mn 0.40%, Mg 2.0%, Zn6.5%, Ti 0.03%, the balance is aluminum and inevitable impurities.

[0043] The aluminum ingots, intermediate alloy ingots and electrolytic aluminum water raw materials are subjected to semi-continuous casting, homogenization heat treatment, sawing, milling, heating, hot rolling, cold rolling, solution quenching, and artificial aging. Strength 7 series aluminum sheet; the specific steps are as follows:

[0044] (1) According to the alloy composition ratio, semi-continuously cast aluminum ingots, aluminum intermediate alloy ingots and electrolytic aluminum water raw materials into aluminum alloy flat ingots after melting, refining, slag removal, and degassing;

[0045] (2) The semi-continuous ingot is subjected to a homogenization heat treatment at 440°C...

Embodiment 2

[0054] A method for preparing an ultra-high-strength 7-series aluminum sheet, wherein the chemical composition of the aluminum alloy sheet and strip is calculated by mass fraction: Si0.08%, Fe0.10%, Cu0.70%, Mn 0.59%, Mg 1.75%, Zn5.6%, Ti 0.015%, the balance is aluminum and inevitable impurities.

[0055] The aluminum ingots, intermediate alloy ingots and electrolytic aluminum water raw materials are subjected to semi-continuous casting, homogenization heat treatment, sawing, milling, heating, hot rolling, cold rolling, solution quenching, and artificial aging. Strength 7 series aluminum sheet; the specific steps are as follows:

[0056] (1) According to the alloy composition ratio, semi-continuously cast aluminum ingots, aluminum intermediate alloy ingots and electrolytic aluminum water raw materials into aluminum alloy flat ingots after melting, refining, slag removal, and degassing;

[0057] (2) The semi-continuous ingot is subjected to a homogenization heat treatment at 4...

Embodiment 3

[0066] A method for preparing an ultra-high-strength 7-series aluminum sheet, wherein the chemical composition of the aluminum alloy sheet and strip is calculated by mass fraction: Si0.18%, Fe0.30%, Cu0.80%, Mn 0.49%, Mg 1.90%, Zn6.8%, Ti 0.04%, the balance is aluminum and inevitable impurities.

[0067] The aluminum ingots, intermediate alloy ingots and electrolytic aluminum water raw materials are subjected to semi-continuous casting, homogenization heat treatment, sawing, milling, heating, hot rolling, cold rolling, solution quenching, and artificial aging. Strength 7 series aluminum sheet; the specific steps are as follows:

[0068] (1) According to the alloy composition ratio, semi-continuously cast aluminum ingots, aluminum intermediate alloy ingots and electrolytic aluminum water raw materials into aluminum alloy flat ingots after melting, refining, slag removal, and degassing;

[0069] (2) The semi-continuous ingot is subjected to a homogenization heat treatment at 46...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com