Production and processing method of pearlitic steel rail and lifting and moving steel lifting machine

A pearlitic steel rail and processing method technology, applied in heat treatment furnaces, heat treatment equipment, furnaces, etc., can solve the problems of reducing the overall service life of the steel rail, affecting the overall performance of the steel rail, affecting the flatness of the steel rail, etc. The effect of layer spacing, improving overall service life and reducing the probability of occurrence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0026] Pearlitic rail production and processing method provided by the present invention comprises the following steps:

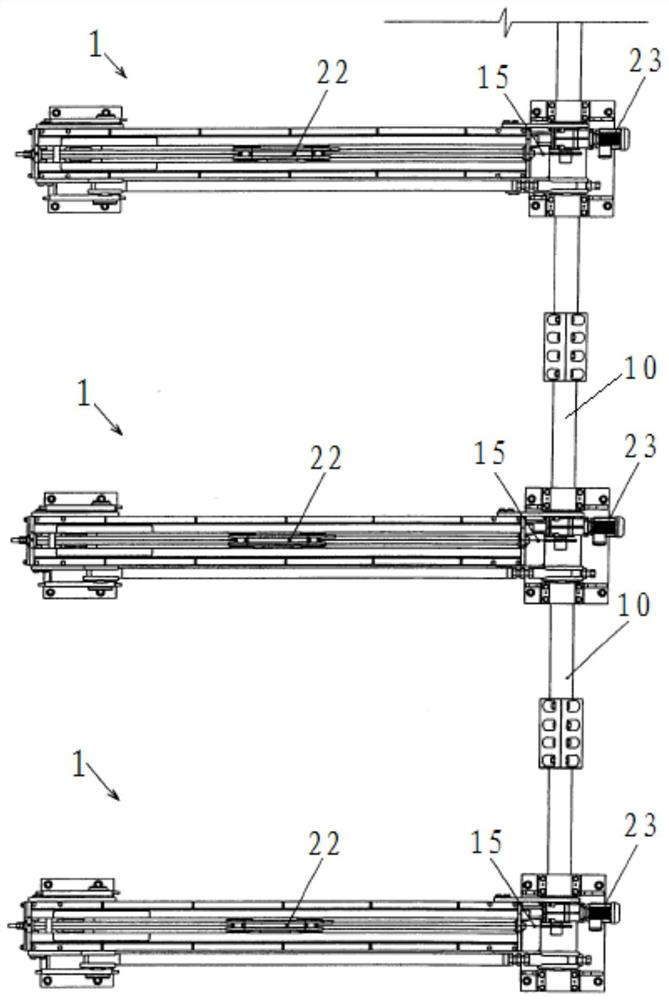

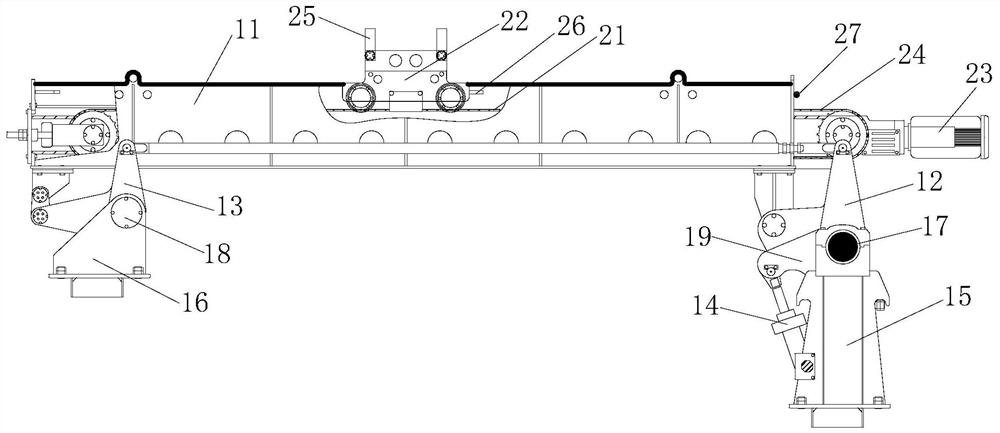

[0027] a. Place the rolled pearlitic rail on the elevating and lifting steel-moving machine, and transport the pearlitic rail through the elevating and elevating steel-moving machine;

[0028] b. During the transportation of the pearlitic steel rail, the lifting and steel moving machine exerts force on the pearlitic steel rail, so that when the pearlite steel rail is transported to the entrance of the heat treatment unit, the pearlite steel rail realizes S-shaped bending deformation or round shape on the horizontal plane. arc bending deformation;

[0029] c. The pearlitic steel rail is transported to the entrance of the heat treatment unit;

[0030] d. Send the pearlitic rail into the heat treatment unit, which is equipped with a c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com