ZnO grading nanoarray on graphene substrate and preparation method and application thereof

A technology of graphene nanosheets and nanoarrays, applied in chemical instruments and methods, final product manufacturing, sustainable manufacturing/processing, etc., can solve problems such as uneven distribution, lower device operating temperature, and addition of foreign impurities, etc., to achieve Effects of avoiding contamination, easy access, and low defect density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

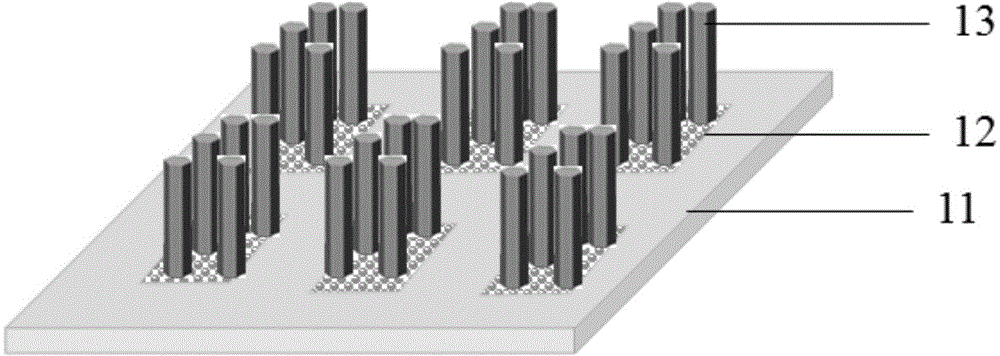

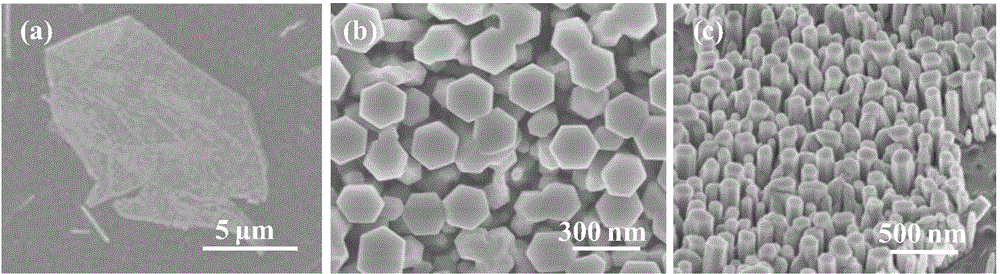

[0028] The preparation method of the hierarchical ZnO nano-array grown on the graphene nanosheet substrate in this embodiment comprises the following steps:

[0029] (1) Using graphene nanosheets as the substrate: Spin-coat the prepared graphene nanosheets (5-15um in diameter, 0.5nm in thickness, and 0.1mg / ml in concentration) on conventional substrates such as n-Si substrates , the number of spin coatings is 3 times, and the spin coating speed is 1000rmp;

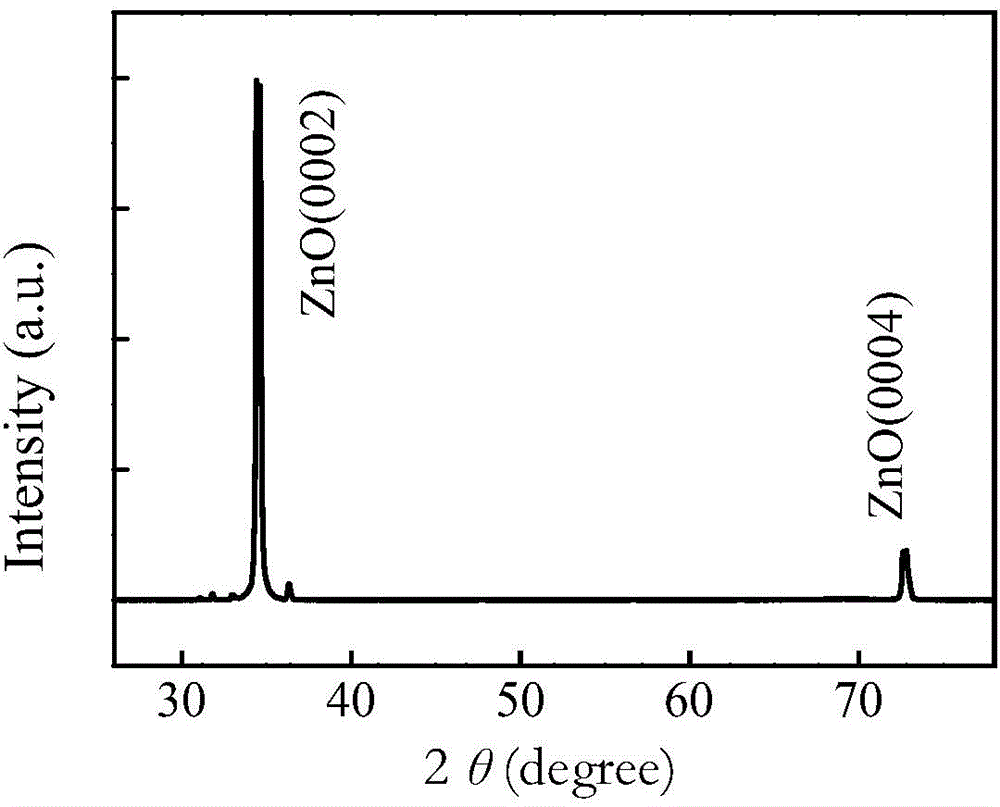

[0030] (2) Non-catalytic growth of hierarchical ZnO nanoarrays by CVD method: the above-mentioned graphene nanosheet spin-coated substrate was placed in a CVD horizontal tube furnace, and non-catalytic growth of hierarchical ZnO nanoarrays was carried out by common chemical vapor deposition CVD method. By controlling the process parameters of the tube furnace: atmosphere flow rate (oxygen flow rate is 40 sccm, argon gas rate is 40 sccm), growth temperature is 600°C, growth time is 120 min, and the graphene substrate is pla...

Embodiment 2

[0036] The preparation method of the hierarchical ZnO nano-array grown on the graphene nanosheet substrate in this embodiment comprises the following steps:

[0037] (1) Using graphene nanosheets as the substrate: Spin-coat the prepared graphene nanosheets (50-100um in diameter, 2nm in thickness, and 1mg / ml in concentration) on other substrates, Si substrate, sapphire substrate, etc. Conventional substrates such as bottoms, the number of times of spin coating is 1 time, and the spin coating speed is 6000rmp;

[0038] (2) Non-catalytic growth of hierarchical ZnO nanoarrays by CVD method: the above-mentioned graphene nanosheet spin-coated substrate was placed in a CVD horizontal tube furnace, and non-catalytic growth of hierarchical ZnO nanoarrays was carried out by common chemical vapor deposition CVD method. By controlling the process parameters of the tube furnace: atmosphere flow rate (oxygen flow rate is 200 sccm, argon gas rate is 200 sccm), growth temperature is 800°C, gr...

Embodiment 3

[0041] The preparation method of the hierarchical ZnO nano-array grown on the graphene nanosheet substrate in this embodiment comprises the following steps:

[0042] (1) Using graphene nanosheets as the substrate: Spin-coat the prepared graphene nanosheets (15-50um in diameter, 1nm in thickness, and 0.5mg / ml in concentration) on other substrates, n-Si and sapphire Conventional substrates such as substrates, the number of spin coatings is 2 times, and the spin coating speed is 3000rmp;

[0043] (2) Non-catalytic growth of hierarchical ZnO nanoarrays by CVD method: the above-mentioned graphene nanosheet spin-coated substrate was placed in a CVD horizontal tube furnace, and non-catalytic growth of hierarchical ZnO nanoarrays was carried out by common chemical vapor deposition CVD method. By controlling the process parameters of the tube furnace: atmosphere flow rate (oxygen flow rate is 100 sccm, argon gas is 100 sccm), growth temperature is 700°C, growth time is 60 min, and the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com