Quick spheroidizing annealing process of bearing steel tubes

A bearing steel pipe and spheroidizing annealing technology, which is applied in the field of bearing steel heat treatment, can solve the problems of long time consumption and inability to achieve rapid spheroidization, and achieve the increase of carbon unevenness, shortening the time of spheroidizing annealing, and good structural properties Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

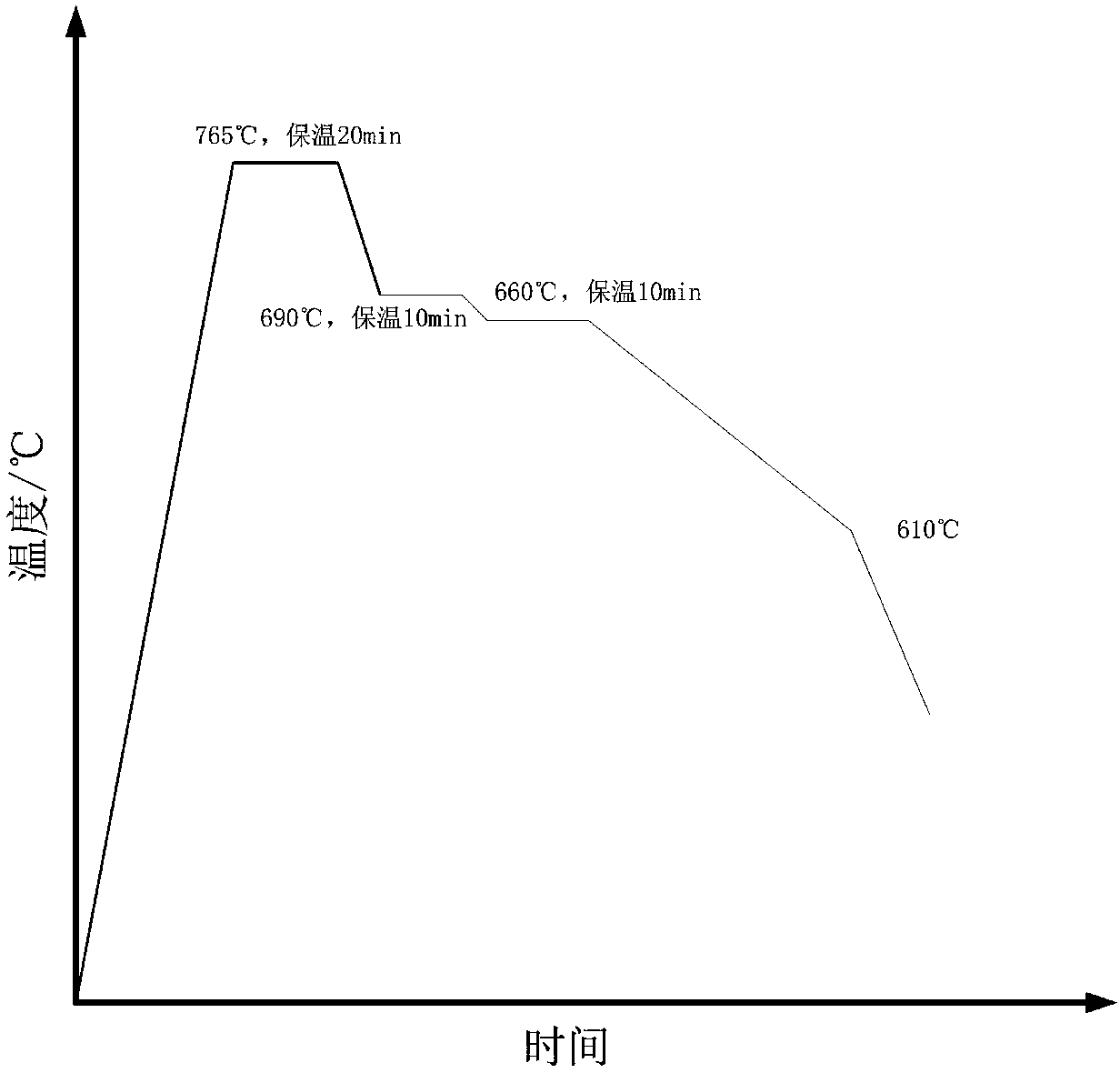

[0028] Such as figure 1 As shown, the components used in this embodiment include by weight percentage: C: 0.95-1.05%, Cr: 1.40-1.65%, Mn: 0.2-0.45%, Si: 0.15-0.3%, Ni≤0.3, P≤0.025, S ≤0.025, Mo≤0.025, Cu≤0.025GCr15 bearing steel pipe as an example, the spheroidizing annealing process includes the following steps:

[0029] Step 1): Heat the bearing steel pipe to 765°C and keep it warm for 20 minutes;

[0030] Step 2): Cool the bearing steel pipe after the first heat preservation to 690°C and keep it warm for 10 minutes;

[0031] Step 3): repeat step 1) and step 2) once, and carry out multiple cycles of heat treatment on the bearing steel pipe after the second heat preservation;

[0032] Step 4): Cool the bearing steel pipe that has undergone multiple heat treatments to 660°C with the furnace, and keep it warm for 10 minutes;

[0033] Step 5): cooling the heat-insulated bearing steel pipe in step 4) to 610°C with the furnace;

[0034] Step 6): air-cool the furnace-cooled bea...

Embodiment 2

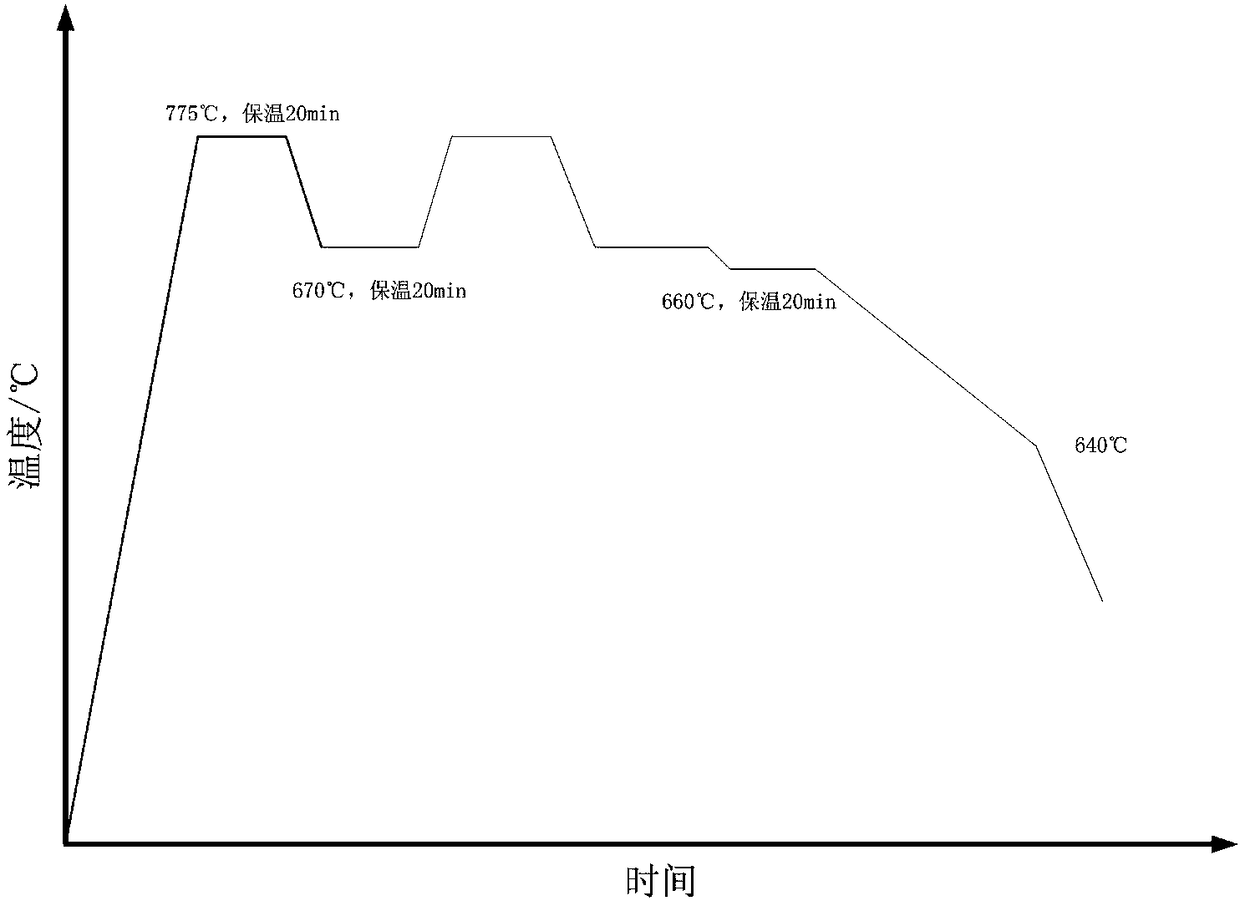

[0037] Such as figure 2 As shown, the components used in this embodiment include by weight percentage: C: 0.95-1.05%, Cr: 1.40-1.65%, Mn: 0.2-0.45%, Si: 0.15-0.3%, Ni≤0.3, P≤0.025, S ≤0.025, Mo≤0.025, Cu≤0.025GCr15 bearing steel pipe as an example, the spheroidizing annealing process includes the following steps:

[0038] Step 1): Heat the bearing steel pipe to 775°C and keep it warm for 20 minutes;

[0039] Step 2): Cool the bearing steel pipe after the first heat preservation to 670°C and keep it warm for 20 minutes;

[0040] Step 3): Repeat step 1) and step 2) twice, and perform multiple cycle heat treatment on the bearing steel pipe after the second heat preservation;

[0041] Step 4): Cool the bearing steel pipe that has undergone multiple heat treatments to 660°C with the furnace, and keep it warm for 20 minutes;

[0042] Step 5): cooling the heat-insulated bearing steel pipe in step 4) to 640°C with the furnace;

[0043] Step 6): air-cool the furnace-cooled bearing...

Embodiment 3

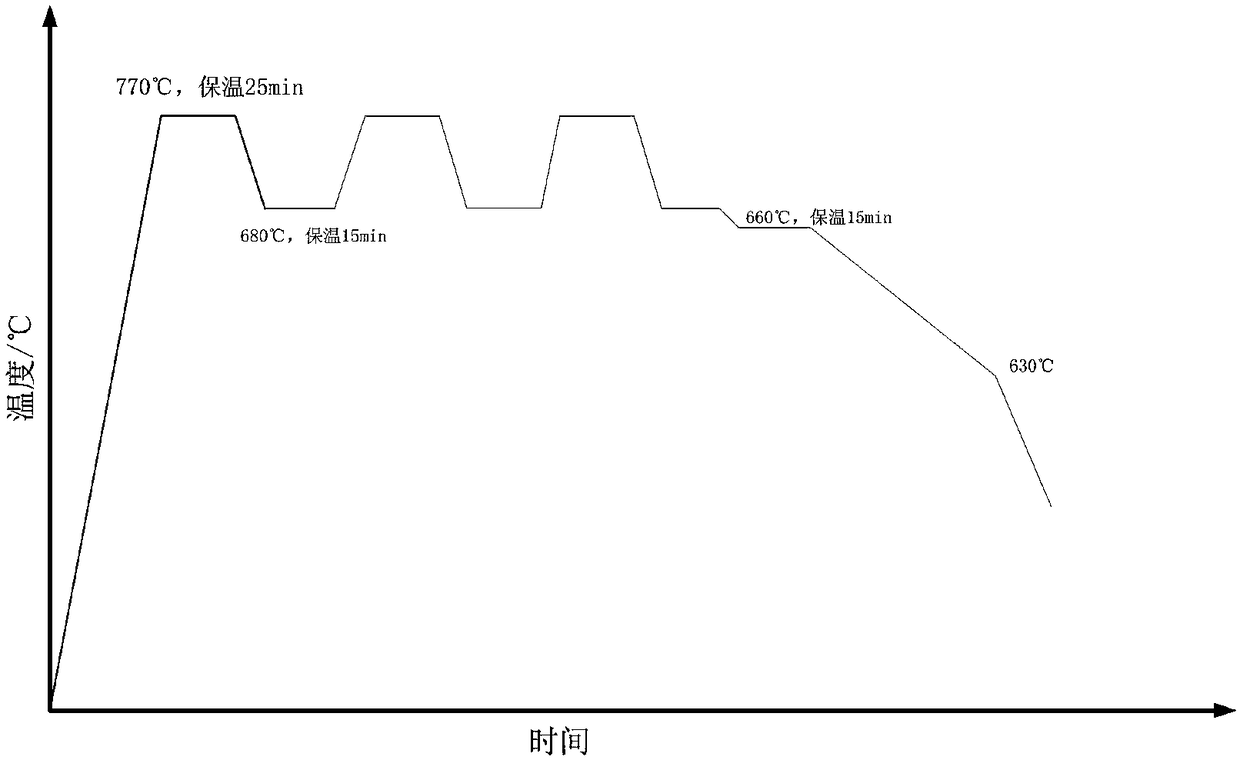

[0046] Such as image 3 As shown, the components used in this embodiment include by weight percentage: C: 0.95-1.05%, Cr: 1.40-1.65%, Mn: 0.2-0.45%, Si: 0.15-0.3%, Ni≤0.3, P≤0.025, S ≤0.025, Mo≤0.025, Cu≤0.025GCr15 bearing steel pipe as an example, the spheroidizing annealing process includes the following steps:

[0047] Step 1): Heat the bearing steel pipe to 770°C and keep it warm for 25 minutes;

[0048] Step 2): Cool the bearing steel pipe after the first heat preservation to 680°C and keep it warm for 15 minutes;

[0049] Step 3): Repeat step 1) and step 2) three times, and perform multiple cycle heat treatment on the bearing steel pipe after the second heat preservation;

[0050] Step 4): Cool the bearing steel pipe that has undergone multiple heat treatments to 660°C with the furnace, and keep it warm for 15 minutes;

[0051] Step 5): cooling the heat-insulated bearing steel pipe in step 4) to 630°C with the furnace;

[0052] Step 6): air-cool the furnace-cooled be...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com