Novel graphite semi-steel bar and finished product roller and production method thereof

A graphite semi-steel, production method technology, applied in the direction of rolls, furnace types, metal rolling, etc., can solve the problems of poor roll stability, short service life, high production cost, etc., to improve quality, improve purity, and increase production The effect of efficiency and effectiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

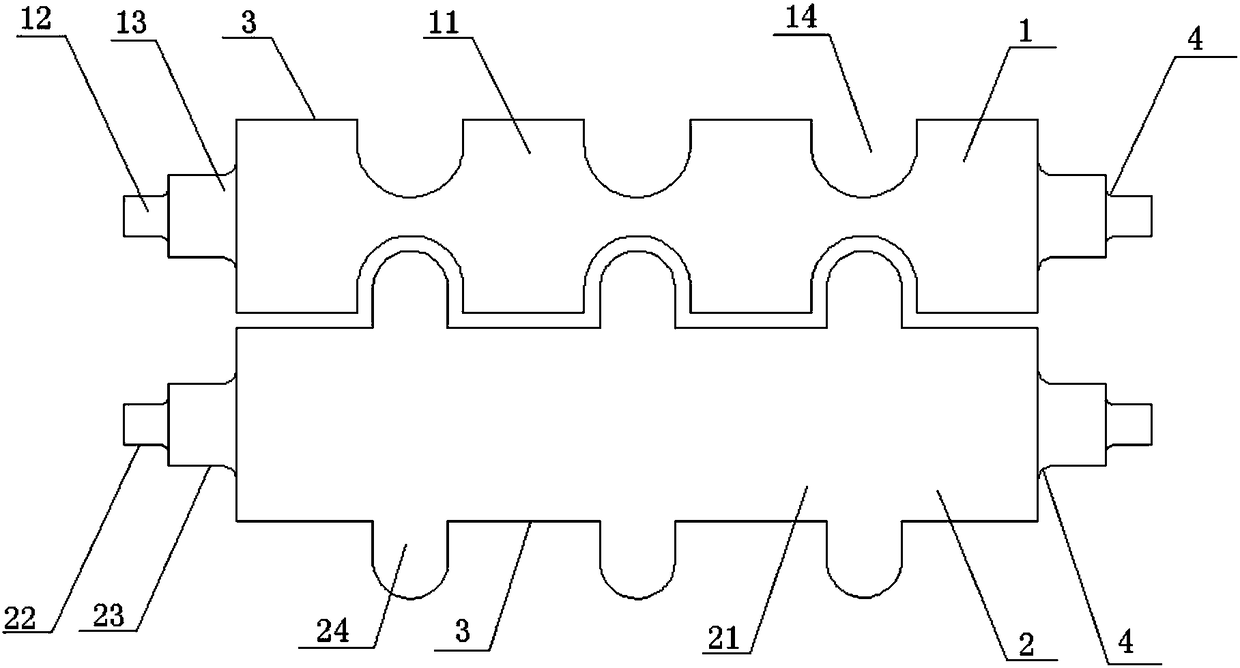

Image

Examples

Embodiment 1

[0032] This embodiment is a method for producing a new type of graphite semi-steel profile and finished product rolls; including the following steps:

[0033] Step 1: Configure the chemical composition: C: 1.60%, Si: 1.50%, Mn: 0.60%, Cr: 0.80%, Ni: 3.20%, Mo: 0.50%, V: 0.1%, Nb: 0.30%, Co: 0.20 %, Re: 0.06%, P≤0.01%, S≤0.01%, Ba+Ca: 0.45%; the balance is Fe and a small amount of residual elements;

[0034] Step 2: After smelting in an intermediate frequency electric furnace, the molten steel is tapped at 1550~1580℃ and poured into the LF ladle refining furnace for refining. When the liquid phase temperature is higher than 120℃, the steel is tapped and the argon gas is blown to oscillate. A 6-channel wire feeder is used: 2 channel rare earth magnesium + 2 channel BaCa spheroidizing agent + 2 channel CaSi inoculant, extend into the ladle at a speed of 8 meters per second, and incubate while spheroidizing. After the strip is processed, the molten steel is calmed for 5-8 minutes until...

Embodiment 2

[0040] This embodiment is a method for producing a new type of graphite semi-steel profile and finished product rolls; including the following steps:

[0041] Step 1: Configure the chemical composition: C: 1.80%, Si: 1.80%, Mn: 0.90%, Cr: 1.0%, Ni: 3.60%, Mo: 0.80%, V: 0.2%, Nb: 0.20%, Co: 0.10 %, Re: 0.10%, P≤0.015%, S≤0.01%, Ba+Ca: 0.55%; the balance is Fe and a small amount of residual elements;

[0042] Step 2: After smelting in an intermediate frequency electric furnace, the molten steel is tapped to 1550~1580℃ and poured into the LF ladle refining furnace for refining. When the liquid temperature is higher than 140℃, the steel will be tapped and the argon gas will be blown to oscillate. A 6-channel wire feeder is used: 2 channel rare earth magnesium + 2 channel BaCa nodulizer + 2 channel CaSi inoculant, extend into the ladle at a speed of 12 meters per second, incubate while spheroidizing. After the strip is processed, the molten steel is calmed for 5-8 minutes until the stee...

Embodiment 3

[0046] This embodiment is a method for producing a new type of graphite semi-steel profile and finished product rolls; including the following steps:

[0047] Step 1: Configure chemical composition: C: 2.0%, Si: 1.90%, Mn: 1.20%, Cr: 1.2%, Ni: 4.00%, Mo: 1.00%, V: 0.3%, Nb: 0.10%, Co: 0.30 %, Re: 0.15%, P≤0.005%, S≤0.01%, Ba+Ca: 0.65%; the balance is Fe and a small amount of residual elements;

[0048] Step 2: After smelting in an intermediate frequency electric furnace, the molten steel is tapped to 1550~1580℃ and poured into the LF ladle refining furnace for refining. When the liquid temperature is higher than 160℃, the steel is tapped and the argon gas is blown to oscillate. A 6-channel wire feeder is used: 2 channel rare earth magnesium + 2 channel BaCa spheroidizing agent + 2 channel CaSi inoculant, extend into the ladle at a speed of 15 meters per second, and incubate while spheroidizing. After the strip is processed, the molten steel is calmed for 5-8 minutes until the steel...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com