Titanium and antimony-containing hot dipping zinc plating aluminum magnesium alloy and preparation method thereof

A technology of hot-dip galvanizing, aluminum-magnesium alloy, applied in hot-dip galvanizing process, metal material coating process, coating, etc., to reduce the loss of zinc, reduce the spacing between layers, improve scratch resistance and resistance Corrosive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

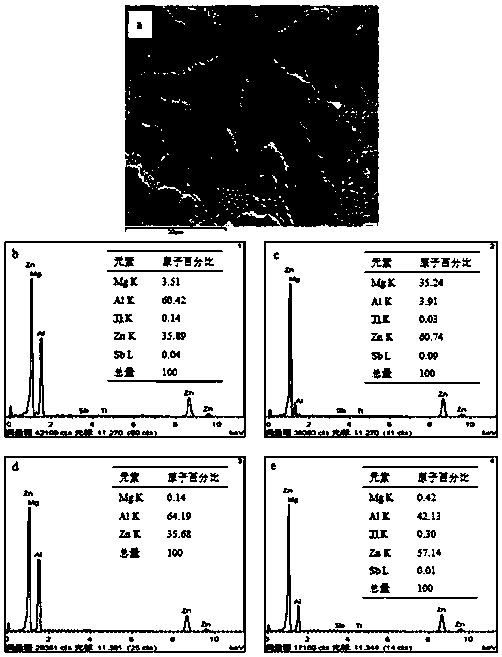

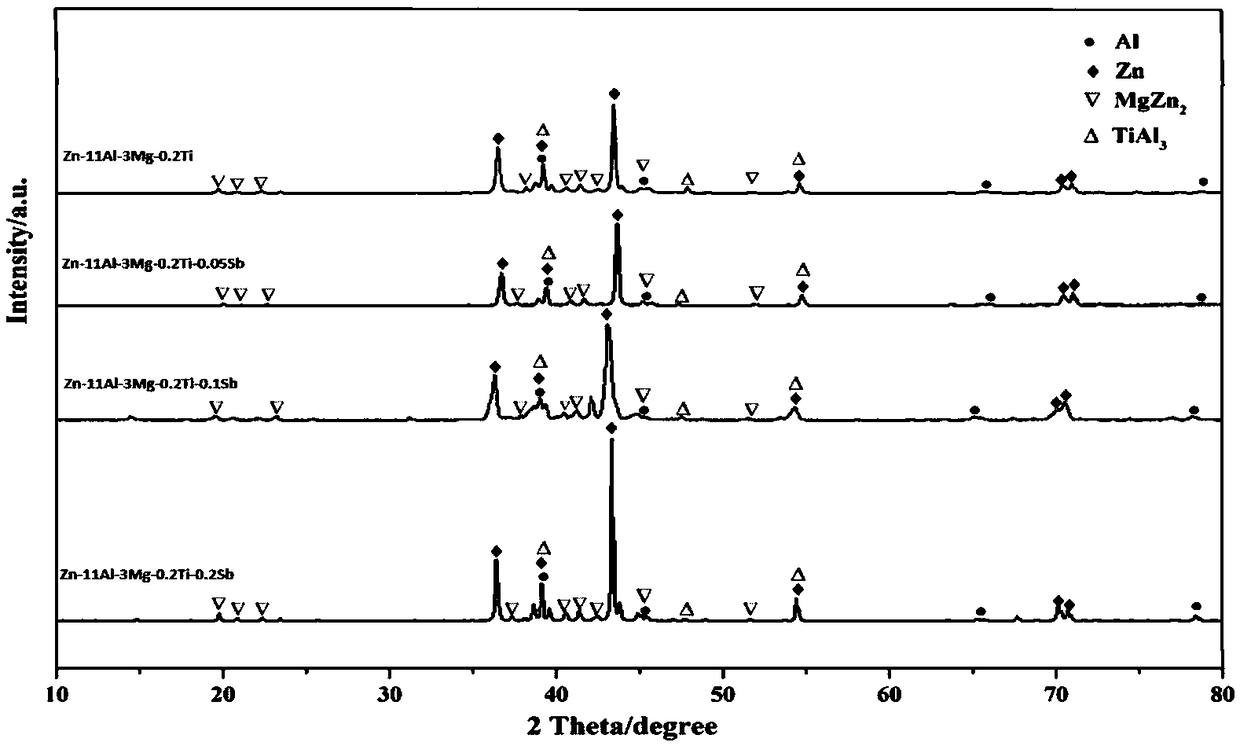

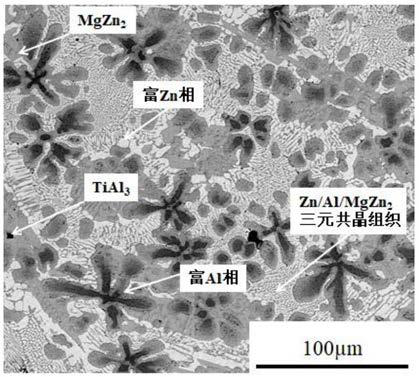

Image

Examples

Embodiment 1

[0034] (1) Weigh the pure zinc block, pure aluminum block, Al-50%Mg master alloy, Al-5%Ti master alloy and Al-5%Sb master alloy according to the proportion. The composition of the alloy is: Al: 11 wt.%, Mg: 3 wt.%, Ti: 0.2 wt.%, Sb: 0.1 wt.%, and the balance is Zn;

[0035] (2) Put the graphite crucible in the resistance furnace to preheat to dark red, place the weighed pure aluminum block in the crucible, and then heat the resistance furnace to 700℃;

[0036] (3) After the pure aluminum is melted, add pure zinc blocks, stir evenly to form a zinc-aluminum alloy solution, at this time add a covering agent to completely cover the alloy solution, and the covering agent is dehydrated containing 50 wt.% NaCl and 50 wt. .% KCl solid powder;

[0037] (4) After the covering agent is melted, add Al-50%Mg master alloy to the alloy liquid and press it below the alloy liquid level to prevent its burning loss;

[0038] (5) After the magnesium block is melted, properly stir the alloy liqu...

Embodiment 2

[0043](1) Weigh the pure zinc block, pure aluminum block, Al-50%Mg master alloy, Al-5%Ti master alloy and Al-5%Sb master alloy according to the proportion. The composition of the alloy is: Al: 11 wt.%, Mg: 3 wt.%, Ti: 0.2 wt.%, Sb: 0.2 wt.%, and the balance is Zn;

[0044] (2) Put the graphite crucible in the resistance furnace to preheat to dark red, place the weighed pure aluminum block in the crucible, and then heat the resistance furnace to 720℃;

[0045] (3) After the pure aluminum is melted, add pure zinc blocks, stir evenly to form a zinc-aluminum alloy solution, and at this time add a covering agent to completely cover the alloy solution. The covering agent is dehydrated containing 40 wt.% NaCl and 60 wt. .% KCl solid powder;

[0046] (4) After the covering agent is melted, add pure magnesium block to the alloy liquid and press it below the alloy liquid level to prevent its burning loss;

[0047] (5) After the magnesium block is melted, properly stir the alloy liquid...

Embodiment 3

[0053] (1) Weigh the pure zinc block, pure aluminum block, Al-50%Mg master alloy, Al-5%Ti master alloy and Al-5%Sb master alloy according to the proportion. The composition of the alloy is: Al: 10 wt.%, Mg: 2.5 wt.%, Ti: 0.1 wt.%, Sb: 0.1%, and the balance is Zn;

[0054] (2) Put the graphite crucible in the resistance furnace to preheat to dark red, place the weighed pure aluminum block in the crucible, and then heat the resistance furnace to 710℃;

[0055] (3) After the pure aluminum is melted, add pure zinc blocks, stir evenly to form a zinc-aluminum alloy solution, at this time add a covering agent to completely cover the alloy solution, and the covering agent is dehydrated containing 50 wt.% NaCl and 50 wt. .% KCl solid powder;

[0056] (4) After the covering agent is melted, add Al-50%Mg master alloy to the alloy liquid and press it below the alloy liquid level to prevent its burning loss;

[0057] (5) After the magnesium block is melted, properly stir the alloy liquid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com