Device for refining additive manufactured titanium alloy grains

An additive manufacturing, titanium alloy technology, applied in the field of additive manufacturing, can solve the problems of changing the structure and properties, cracking of parts, limited ability to control columnar crystals, etc., to reduce the possibility and reduce the effect of internal stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

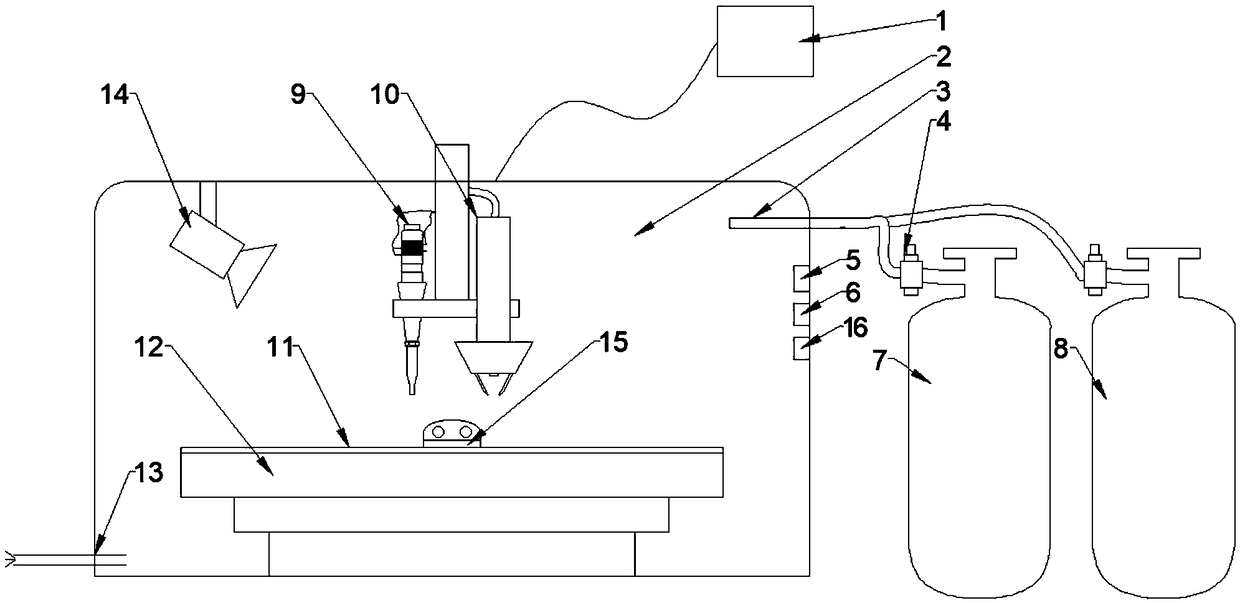

[0046] A device for refining and additively manufacturing titanium alloy grains, the schematic diagram of which is shown in figure 1 , the device includes an atmosphere protection box 2, a laser additive manufacturing system 10, an external force volume deformation system 9, a gas supply system and a control system 1;

[0047] The atmosphere protection box 2 is a closed box, one side of the box is provided with a mixed gas inlet 3, and the opposite side is provided with a gas outlet 13, and a gas supply system is connected to the mixed gas inlet 3;

[0048] The gas supply system is used to provide gas to the atmosphere protection box;

[0049] The casing of the atmosphere protection box 2 is provided with the working part of the laser additive manufacturing system 10 and the working part of the external force volume deformation system 9, the described atmosphere protection box 2, the laser additive manufacturing system 10, and the external force volume deformation system 9. T...

Embodiment 2

[0067] A device for refining titanium alloy grains by additive manufacturing, including an atmosphere protection box 2, a laser additive manufacturing system 10, an external force volume deformation system 9, a gas supply system and a control system 1;

[0068] More specifically, it includes: control system 1, atmosphere protection box 2, mixed gas inlet 3, valve 4, hydrogen concentration monitoring equipment 5, air pressure sensor 6, hydrogen cylinder 7, nitrogen cylinder 8, external force volume deformation system 9, laser additive manufacturing system 10. Temperature regulating plate 11, mobile platform 12, gas outlet 13, infrared camera 14 and hydrogen concentration alarm device 16, the working part of the laser additive manufacturing system 10 and the working part of the external force volume deformation system 9 are installed in the atmosphere protection box 2, a high-precision hydrogen concentration monitoring device 5 is installed on the inner wall of the atmosphere pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com