Austenitic stainless steel plate and manufacture method thereof

A technology of austenitic stainless steel and its manufacturing method, which is applied in the field of austenitic stainless steel plate and its manufacturing, can solve the problems of seldom considering the influence of surface quality, difficulty in smelting, etc., and achieve the effect of good surface quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] In this embodiment, the mass percentage of the chemical composition of the austenitic stainless steel plate is as follows:

[0042] C

mn

Si

S

P

Cr

Ni

Mo

N

O

0.029

1.8

0.41

0.001

0.03

17.8

11.9

2.01

0.035

0.003

[0043] The rest is Fe and other unavoidable impurities

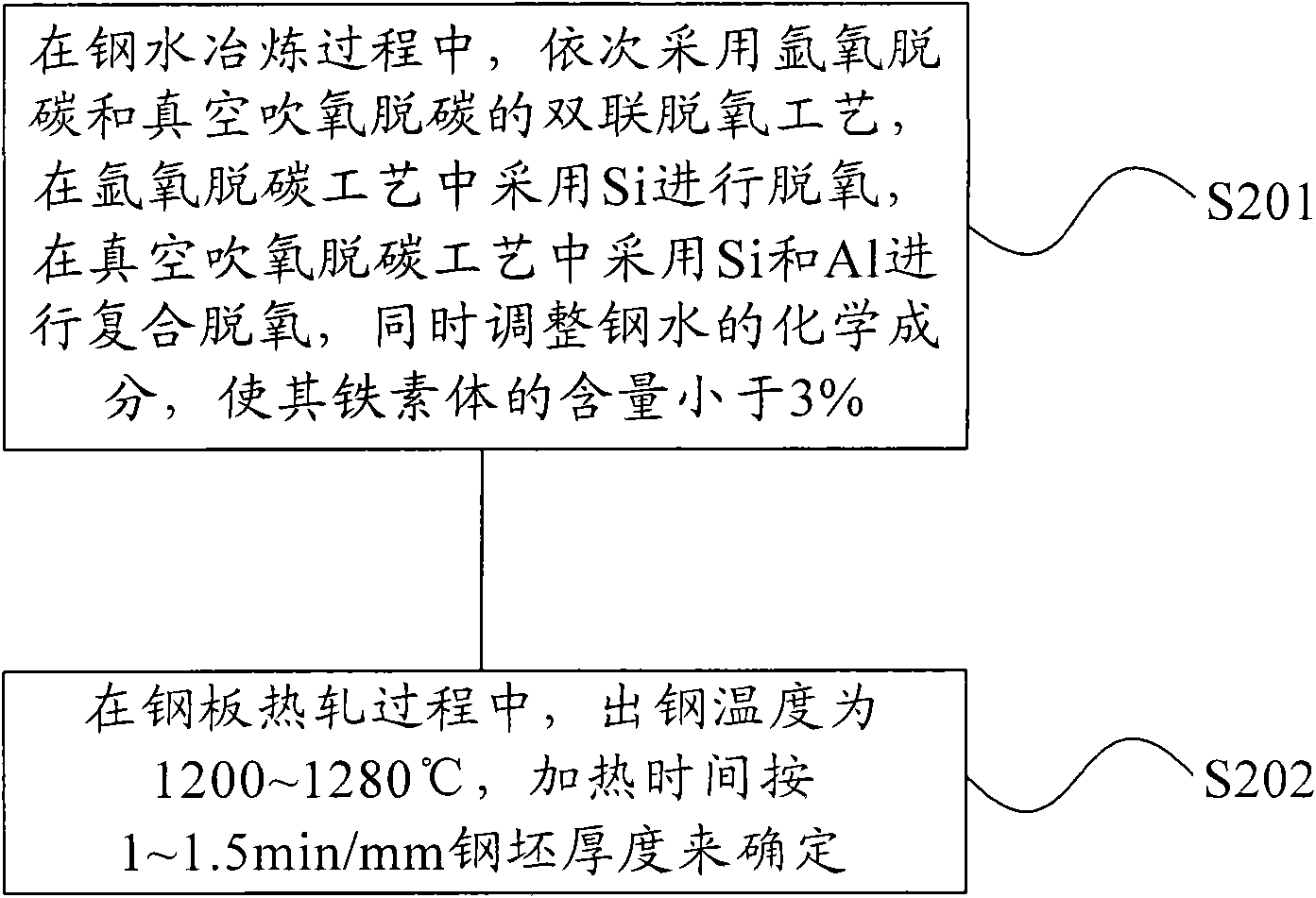

[0044] In the molten steel smelting process, the dual deoxidation process of argon oxygen decarburization (AOD) and vacuum oxygen decarburization (VOD) is adopted in sequence. In the AOD process, Si is used for deoxidation, and in the VOD process, Si and Al are used for composite deoxidation. , and at the same time adjust the chemical composition of molten steel so that the content of ferrite δ is less than 3%.

[0045] In this embodiment, the Si content after the AOD process is controlled to be 0.15%, the amount of Al added in the VOD process is controlled to be 0.9 kg / ton of steel, and the tota...

Embodiment 2

[0050] In this embodiment, the mass percentage of the chemical composition of the austenitic stainless steel plate is as follows:

[0051] C

mn

Si

S

P

Cr

Ni

Mo

N

O

0.022

1.65

0.48

0.001

0.02

16.1

10.2

2.3

0.061

0.0038

[0052] The rest is Fe and other unavoidable impurities

[0053] In the molten steel smelting process, the dual deoxidation process of AOD and VOD is adopted in turn. In the AOD process, Si is used for deoxidation, and in the VOD process, Si and Al are used for composite deoxidation. At the same time, the chemical composition of molten steel is adjusted to make it ferrite. The content of δ is less than 3%.

[0054] In this embodiment, the Si content after the AOD process is controlled to be 0.25%, the amount of Al added in the VOD process is controlled to be 3.5 kg / ton of steel, and the total oxygen content is controlled to be 0.0038%.

[0055] In thi...

Embodiment 3

[0062] In this embodiment, the mass percentage of the chemical composition of the austenitic stainless steel plate is as follows:

[0063] C

mn

Si

S

P

Cr

Ni

Mo

N

O

0.012

1.00

0.8

0.003

0.02

18.8

12.6

1.5

0.07

0.004

[0064] The rest is Fe and other unavoidable impurities

[0065] In the molten steel smelting process, the dual deoxidation process of AOD and VOD is adopted in turn. In the AOD process, Si is used for deoxidation, and in the VOD process, Si and Al are used for composite deoxidation. At the same time, the chemical composition of molten steel is adjusted to make it ferrite. The content of δ is less than 3%.

[0066] In this embodiment, the Si content after the AOD process is controlled to be 0.17%, the amount of Al added in the VOD process is controlled to be 0.7 kg / ton of steel, and the total oxygen content is controlled to be 0.004%.

[0067] In this em...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com