Ultra-pure tantalum with controllable tissues and textures and preparation method and application thereof

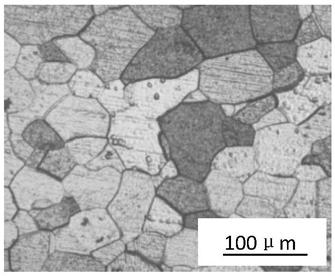

An ultra-high, textured technology, applied in the direction of ion implantation plating, coating, metal material coating process, etc., can solve the problem of uneven thickness of sputtering film, low effective utilization rate of target material, uneven grain size distribution, etc. problem, to achieve the effect of smooth and controllable sputtering evaporation speed, improving the stability of the coating process, and enhancing the strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0062] Pure tantalum ingot (purity 99.997%) formed by cold isostatic pressing, in a high vacuum of 10 -4 Melting in a Pa electron beam melting furnace, the melting temperature is 1330°C, after cooling, the ingot is again placed in a high vacuum -4 Melting is carried out in a Pa electron beam melting furnace at a melting temperature of 1330° C. (each melting time is 2.5 hours). The obtained high-density ingot is sheathed in stainless steel in an argon chamber to prevent the tantalum from being oxidized during the sheathing process, and the sheathing also acts as a solid lubricant during processing to prevent deformation and cracking.

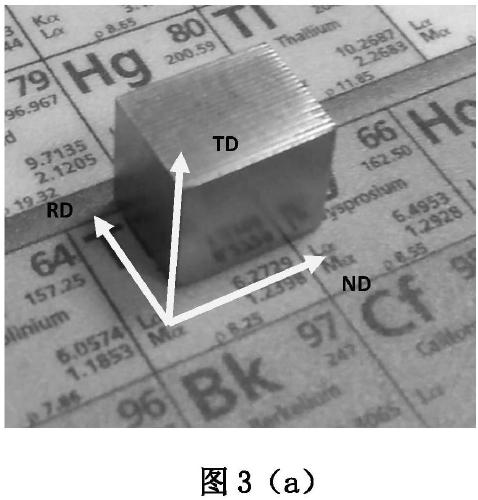

[0063] Heat the sheathed billet to 1200°C, keep it warm for 3 hours, make the axial direction of the billet parallel to the direction of the forging force, and carry out forging. The total deformation is 55%, and the deformation is completed in two passes. The amount of deformation in the first pass is controlled at 35%; rotate the forged billet...

Embodiment 2

[0069] Pure tantalum ingot (purity 99.996%) formed by cold isostatic pressing, in a high vacuum of 10 -4 Melting in a Pa electron beam melting furnace, the melting temperature is 1320°C, after cooling, the ingot is again placed in a high vacuum -4 Melting is carried out in a Pa electron beam melting furnace at a melting temperature of 1320° C. (each melting time is 2.5 hours). The obtained high-density ingot is covered with stainless steel in an argon chamber. Heat the sheathed billet to 1225°C, hold the heat for 2 hours, make the axial direction of the billet parallel to the direction of the forging force, and carry out forging. The total deformation is 55%, and the deformation is completed in two passes. The deformation of the first pass is controlled. At 33%; rotate the forged billet 90°, make the axial direction of the billet perpendicular to the direction of the forging force, and carry out forging. %, every forging, annealing at 1200°C for 1.5 hours. Repeat the above ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| crystal size | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com