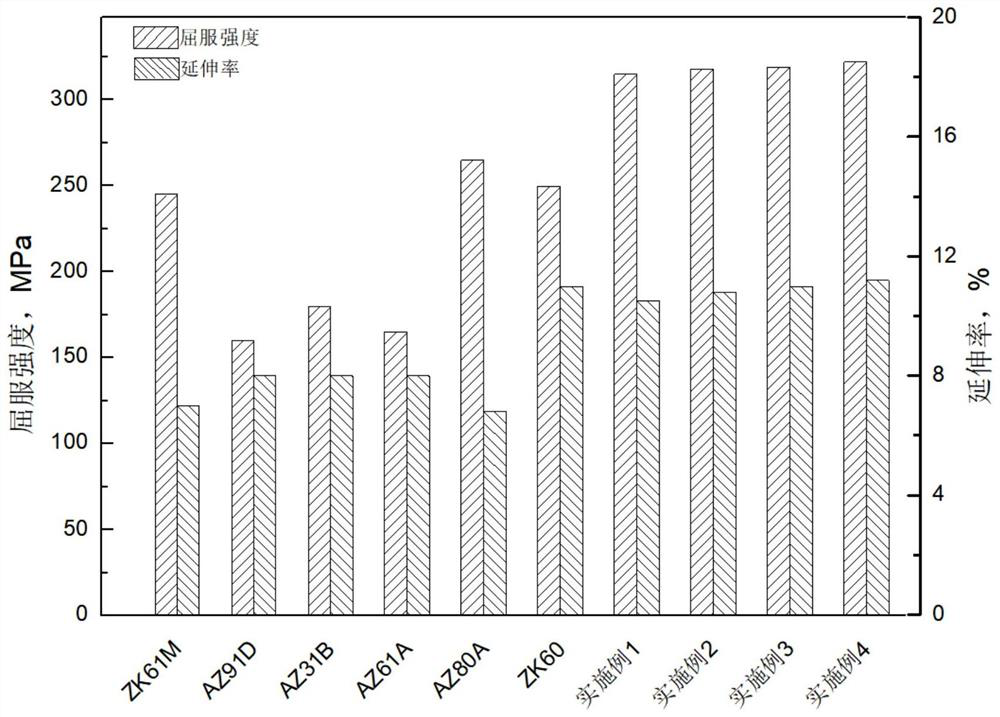

High-strength and high-corrosion-resistance rare earth magnesium alloy and preparation method thereof

A technology of high corrosion resistance and rare earth magnesium, applied in the field of non-ferrous metal processing, can solve the problem of insufficient strength, achieve the effect of improving quality, improving strength and plasticity, and increasing strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] The preparation method of the high-strength and high-corrosion-resistant rare earth magnesium alloy plate of the present invention comprises the following steps:

[0027] Step 1, weighing by mass percentage: aluminum: 6%-8%, mixture of yttrium and gadolinium: 0.4%-0.6%, manganese: 0.2%-0.5%, mixture of lanthanum, cerium and neodymium: 0.2%-0.6 %, and the rest is magnesium; among them, the content of yttrium is 0.2%-0.3% of the mass of high-strength and high-corrosion-resistant rare-earth magnesium alloy, the content of gadolinium is 0.2%-0.3% of the mass of high-strength and high-corrosion-resistant rare-earth magnesium alloy, and the content of lanthanum is The content is 0.05%-0.2% of the mass of high-strength and high-corrosion-resistant rare-earth magnesium alloy, the content of cerium is 0.05%-0.2% of the mass of high-strength, high-corrosion-resistant rare-earth magnesium alloy, and the content of neodymium is high-strength and high-corrosion-resistant rare-earth m...

Embodiment 1

[0039] The preparation method of the high-strength and high-corrosion-resistant rare earth magnesium alloy plate in this embodiment includes the following steps:

[0040] Step 1, take aluminum by weight percentage: 6%, the mixture of yttrium and gadolinium: 0.4%, manganese: 0.2%, the mixture of lanthanum, cerium and neodymium: 0.2%, the rest is magnesium; wherein, the content of yttrium is 0.2% %, the content of gadolinium is 0.2%, the content of lanthanum is 0.05%, the content of cerium is 0.05%, and the content of neodymium is 0.1%;

[0041] Step 2, put the raw materials weighed in step 1 into the melting furnace, add covering agent and refining agent for protection, heat up to 750°C to obtain the molten liquid and keep it warm for 15 minutes, cool down the molten liquid to 720°C and let it stand for 5 minutes, and cast to obtain half Continuous magnesium alloy ingot casting;

[0042] Step 3, keeping the semi-continuous magnesium alloy ingot prepared in step 2 at 380° C. fo...

Embodiment 2

[0049] The preparation method of the high-strength and high-corrosion-resistant rare earth magnesium alloy plate in this embodiment includes the following steps:

[0050] Step 1, weigh aluminum: 6.5%, the mixture of yttrium and gadolinium: 0.45%, manganese: 0.3%, the mixture of lanthanum, cerium and neodymium: 0.25% by weight percentage, and the rest is magnesium; wherein, the content of yttrium is 0.23 %, the content of gadolinium is 0.22%, the content of lanthanum is 0.1%, the content of cerium is 0.1%, and the content of neodymium is 0.05%;

[0051] Step 2, put the raw materials weighed in step 1 into the melting furnace, add covering agent and refining agent for protection, heat up to 760°C to obtain a molten liquid and keep it warm for 17 minutes, cool down the molten liquid to 723°C and let it stand for 7 minutes, and cast to obtain half Continuous magnesium alloy ingot casting;

[0052] Step 3, keeping the semi-continuous magnesium alloy ingot prepared in step 2 at 390...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com