Method for preparing phenolic foam containing expanded graphite

A technology of expanded graphite and phenolic foam, which is applied in the field of polymer foam materials, can solve the problems of brittleness and easy slag drop, poor mechanical properties of phenolic foam, etc., and achieve the effects of low cost, good mechanical properties, and wide sources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

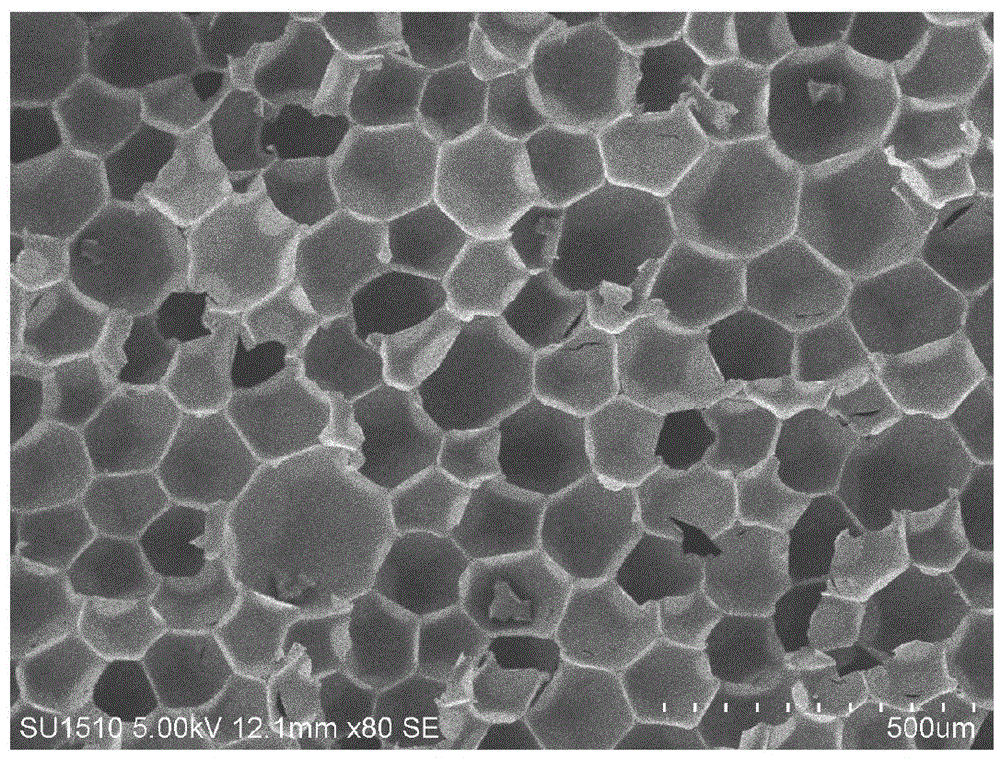

Image

Examples

Embodiment 1

[0028] A preparation method of phenolic foam containing expanded graphite, the method may further comprise the steps:

[0029] (1) Add 100mg of polyacrylic acid and 100mg of N,N'-dicyclohexylcarbodiimide to 50ml of expanded graphite tetrahydrofuran solution with a mass concentration of 0.1% (the particle size of expanded graphite is 100 mesh), and after ultrasonic mixing for 0.5h , at N 2 Protected, under the condition of 60°C, magnetically stirred for 4h, the product was washed with tetrahydrofuran for 3 times and dried to obtain polyacrylic acid-modified expanded graphite;

[0030] (2) 100 mg of polyacrylic acid-modified expanded graphite and 100 mg of N, N'-dicyclohexylcarbodiimide prepared in step (1) were dispersed in 100 mL of anhydrous tetrahydrofuran, and ultrasonically dispersed for 1 h, then in N 2 Under protective conditions, add the dispersion liquid dropwise to 2.8g γ-glycidoxypropyltrimethoxysilane, stir at 60°C for 4h, centrifuge and dry to obtain γ-glycidoxypr...

Embodiment 2

[0035] A preparation method of phenolic foam containing expanded graphite, the method may further comprise the steps:

[0036](1) 100mg polyacrylic acid, 100mgN, N'-dicyclohexylcarbodiimide was added to 50ml mass concentration of 5% expanded graphite tetrahydrofuran solution (the particle size of expanded graphite was 200 mesh), after ultrasonic mixing for 2h, in N 2 Protected, under the condition of 50°C, magnetically stirred for 10h, the product was washed twice with tetrahydrofuran and dried to obtain polyacrylic acid-modified expanded graphite;

[0037] (2) 100 mg of polyacrylic acid-modified expanded graphite and 150 mg of N, N'-dicyclohexylcarbodiimide prepared in step (1) were dispersed in 100 mL of anhydrous tetrahydrofuran, and ultrasonically dispersed for 1 h, then in N 2 Under protective conditions, add the dispersion liquid dropwise to 7.5g γ-glycidoxypropyltrimethoxysilane, stir at 60°C for 4h, centrifuge and dry to obtain γ-glycidoxypropyltrimethoxysilane Expan...

Embodiment 3

[0041] A preparation method of phenolic foam containing expanded graphite, the method may further comprise the steps:

[0042] (1) 100mg polyacrylic acid, 100mgN, N'-dicyclohexylcarbodiimide was added to 50ml mass concentration of 0.5% expanded graphite tetrahydrofuran solution (the particle size of expanded graphite was 500 mesh), after ultrasonic mixing for 1h, in N 2 Protected, under the condition of 70°C, magnetically stirred for 8 hours, the product was washed with tetrahydrofuran for 5 times and dried to obtain polyacrylic acid-modified expanded graphite;

[0043] (2) 100 mg of polyacrylic acid-modified expanded graphite and 200 mg of N, N'-dicyclohexylcarbodiimide prepared in step (1) were dispersed in 100 mL of anhydrous tetrahydrofuran, and ultrasonically dispersed for 1 h, then in N 2 Under protective conditions, add the dispersion liquid dropwise to 5g γ-glycidoxypropyl trimethoxysilane, stir at 60°C for 4 hours, centrifuge and dry to obtain γ-glycidoxypropyl trime...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com