Method for performing two-pass rolling on thickness variable strips

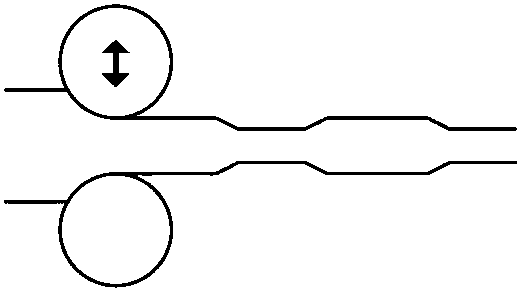

A technology of variable thickness rolling and strip rolling, applied in metal rolling, metal rolling, rolling mill control devices, etc., can solve the problems of high requirements, not easy to achieve, and high requirements for incoming material contour recognition accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

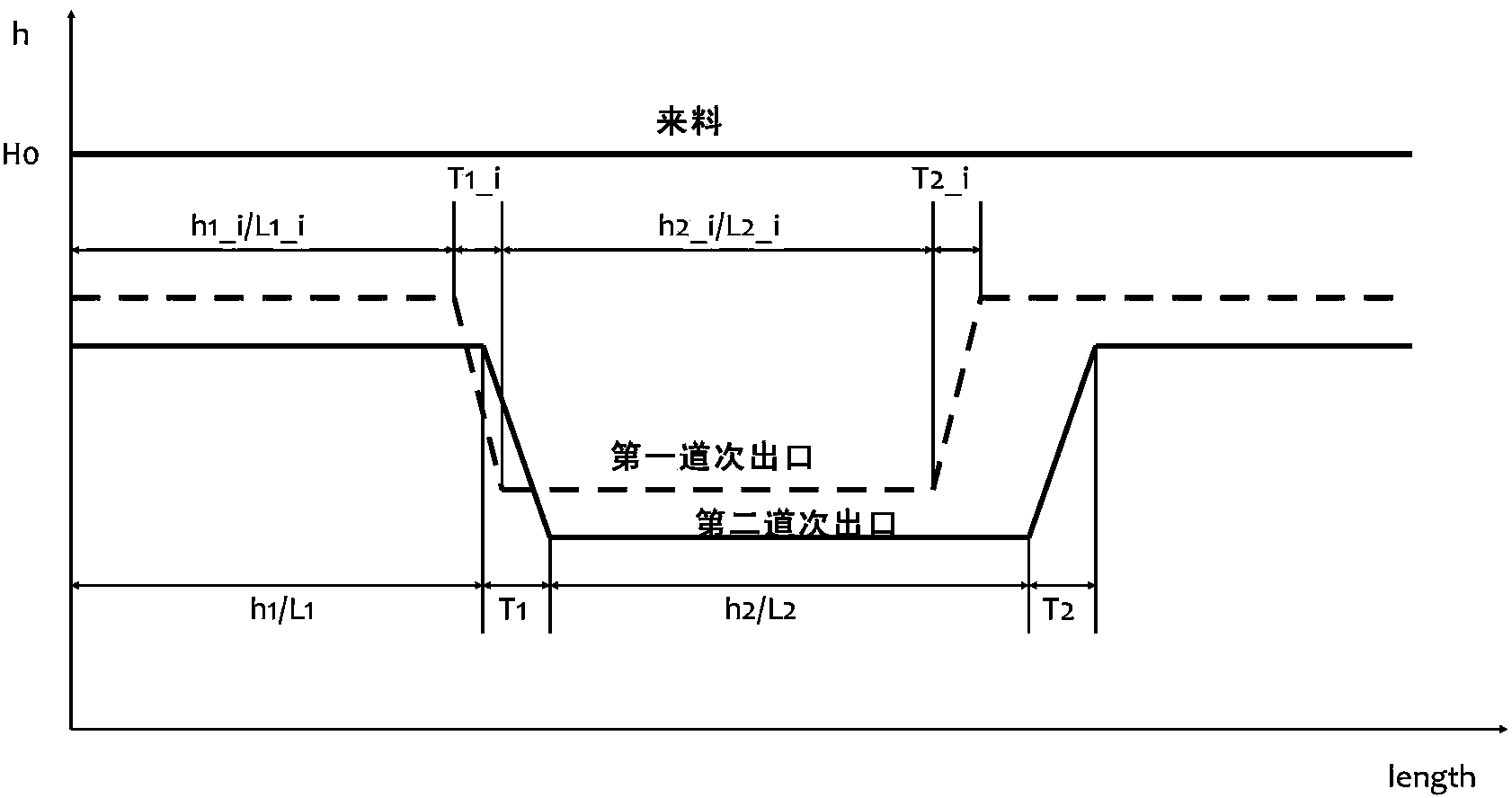

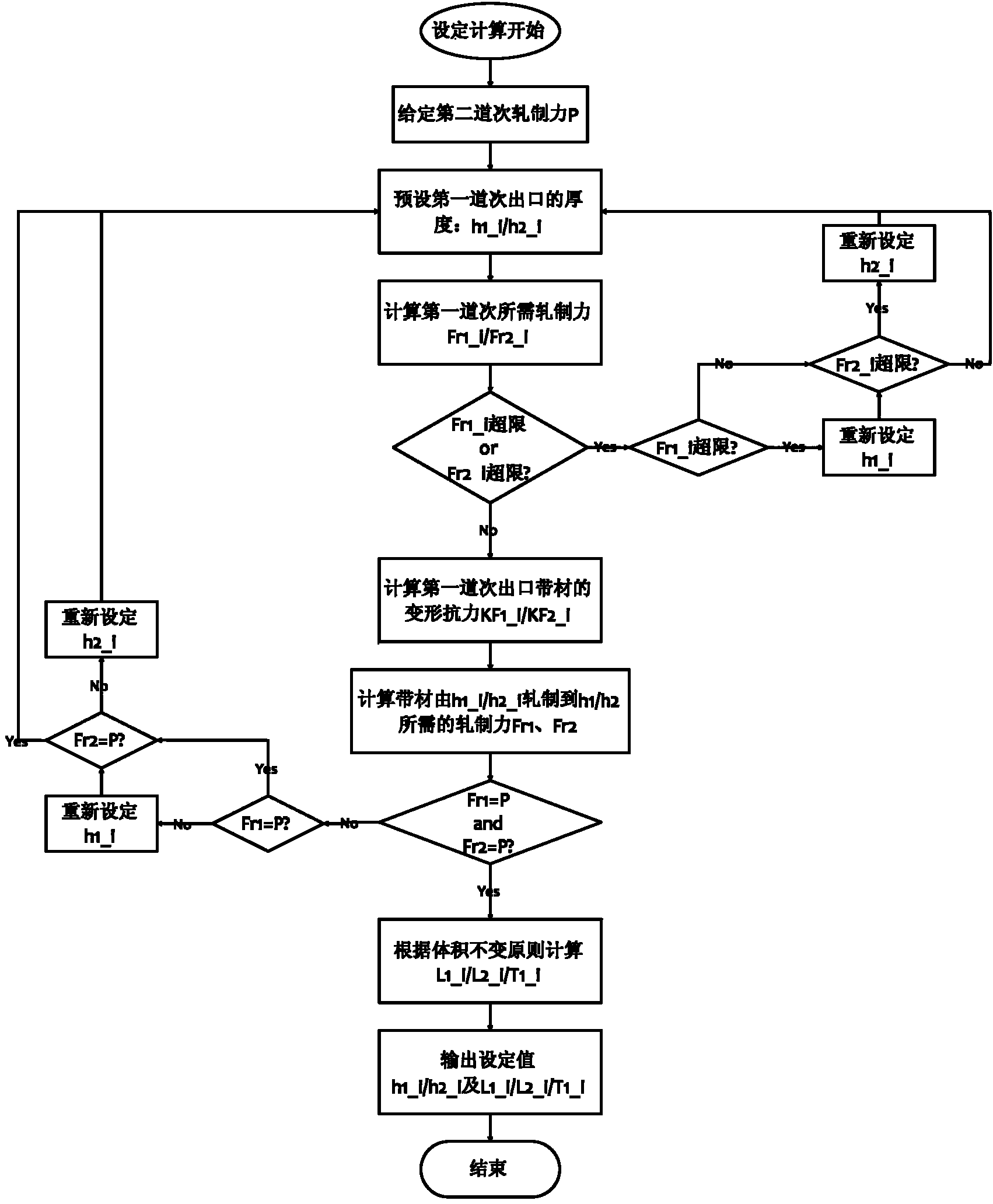

[0092] A certain sample requires a profile after rolling such as Figure 4 As shown, h1=2.0mm, L1=200mm, T1=100mm, h2=1.0mm, L2=700mm, the incoming strip thickness is 2.5mm, the width is 300mm, the diameter of the work roll is 160mm, and the rolling speed is kept at 150mm and s. The material of the incoming material is a certain type of steel, and its deformation resistance calculation formula is k s =k(ε+m) n , the deformation resistance parameters are k=30, m=0.01, n=0.1.

[0093] The model uses the Hill formula to calculate the rolling force:

[0094] P = b · k p · κ · D p R ′ · ( H - h ) × Z p

[0095] In the formula, P—is the r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com