Universal mill type

A rolling mill and universal technology, applied in the direction of metal rolling stand, metal rolling mill stand, metal rolling, etc., can solve the problems of large dimensional tolerance range and poor control accuracy, so as to improve product precision, performance, rolling The effect that it is easy to manufacture high-strength section steel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

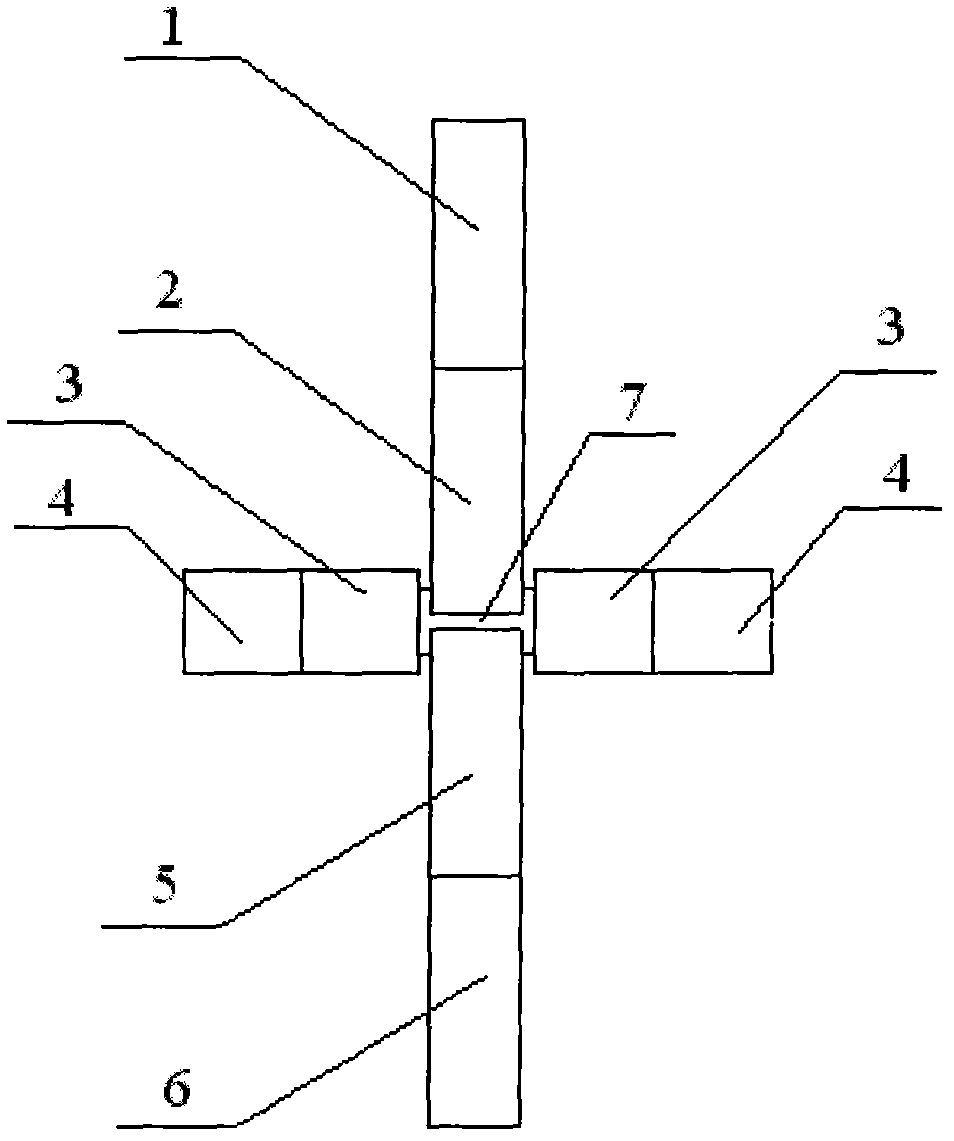

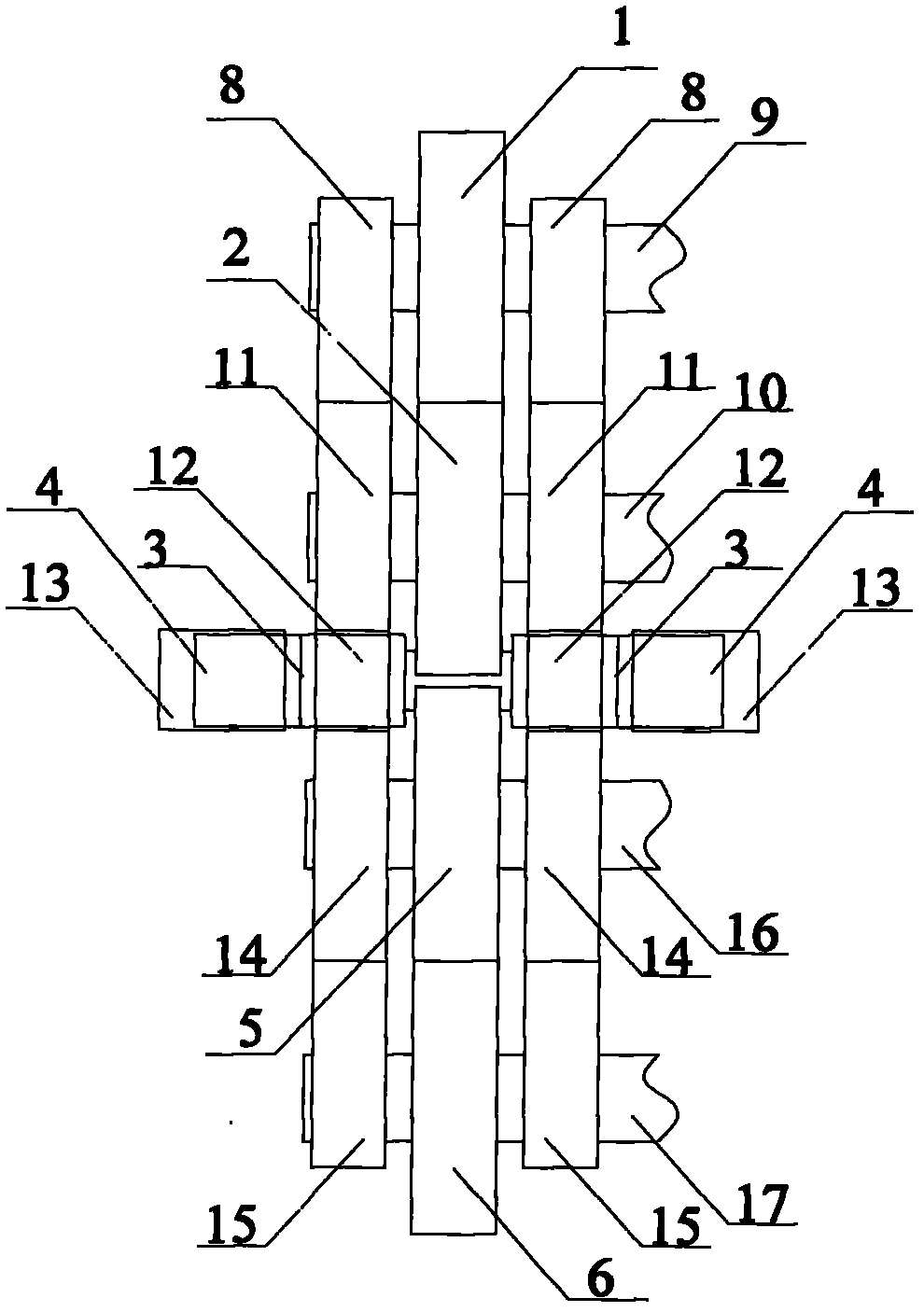

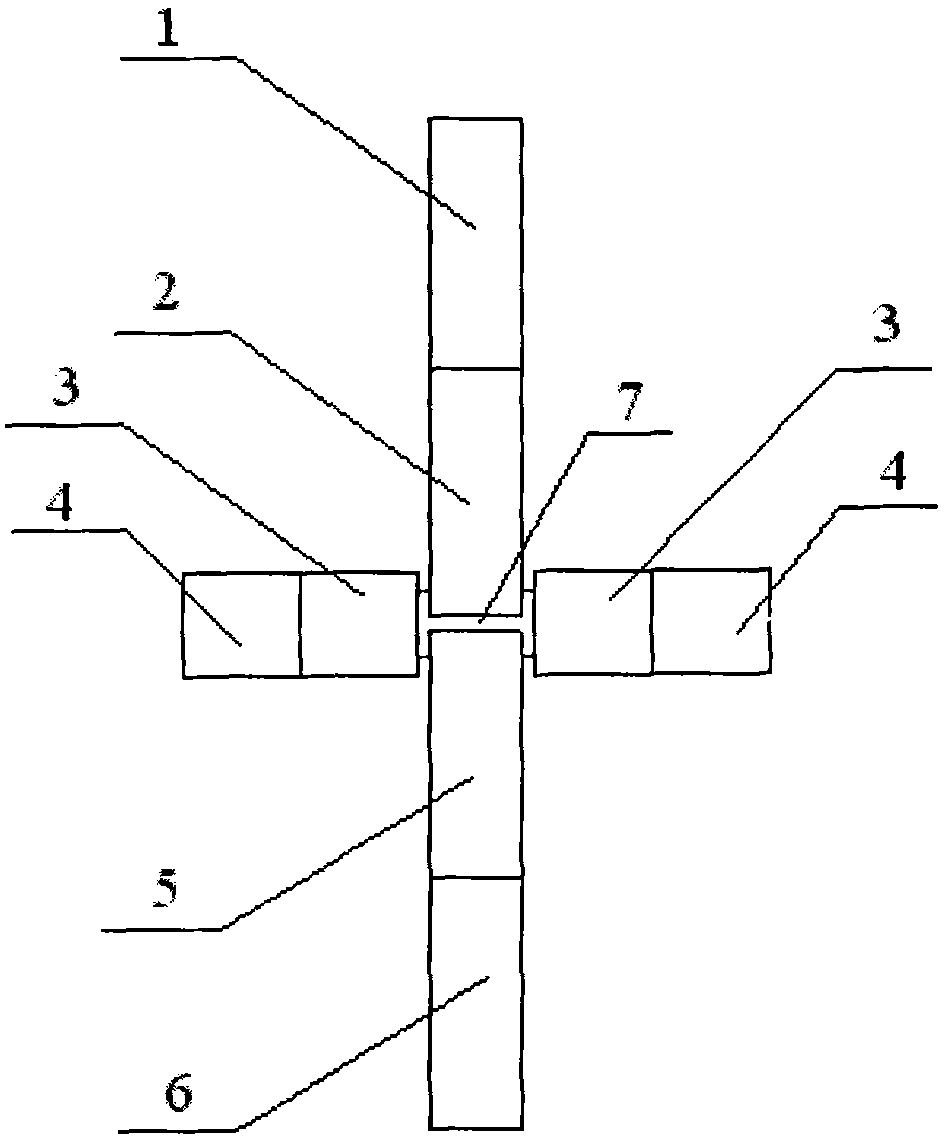

[0024] A type of universal rolling mill, such as figure 1 and figure 2 As shown, an eight-roll structure is adopted, and two horizontal support rolls, the upper horizontal support roll 1 and the lower horizontal support roll 6, are added beside the two horizontal work rolls 2 and 5, and the upper horizontal support roll 1 is located directly above the upper horizontal work roll 2 , the roll shafts 9 on both sides of the upper horizontal back-up roll are inserted into the upper horizontal back-up roll bearing housing 8 with bearings, the lower horizontal back-up roll 6 is located directly below the lower horizontal work roll 5, and the roll shafts on both sides of the lower horizontal back-up roll 17 is inserted in the lower horizontal back-up roll bearing seat 15 that bearing is housed, and the center of four horizontal rolls is on a straight line; A support vertical roll 4 is respectively added on the outside of two work vertical rolls 3, and work vertical roll and support v...

Embodiment 2

[0033] A kind of universal rolling mill type, structure and working method are identical with embodiment 1, difference is:

[0034] The roll diameter of the described horizontal support roll is Φ900mm, and the roll diameter of the horizontal work roll in contact with it is Φ880mm.

[0035] The roll diameter of the support vertical roll is Φ800mm, and the roll diameter of the working vertical roll in contact with it is Φ780mm.

Embodiment 3

[0037] A kind of universal rolling mill type, structure and working method are identical with embodiment 1, difference is:

[0038] The roll diameter of the described horizontal backup roll is Φ710mm, and the roll diameter of the horizontal work roll in contact with it is Φ690mm.

[0039] The roll diameter of the supporting vertical roll is Φ530mm, and the roll diameter of the working vertical roll in contact with it is Φ510mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com