Rolling mill with laterally different velocities

A technology of rolling mills and rolls, applied in the field of transverse differential rolling mills, which can solve the problems of different or uneven distribution in the transverse direction, thinning of edges, convexity of rolled pieces, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

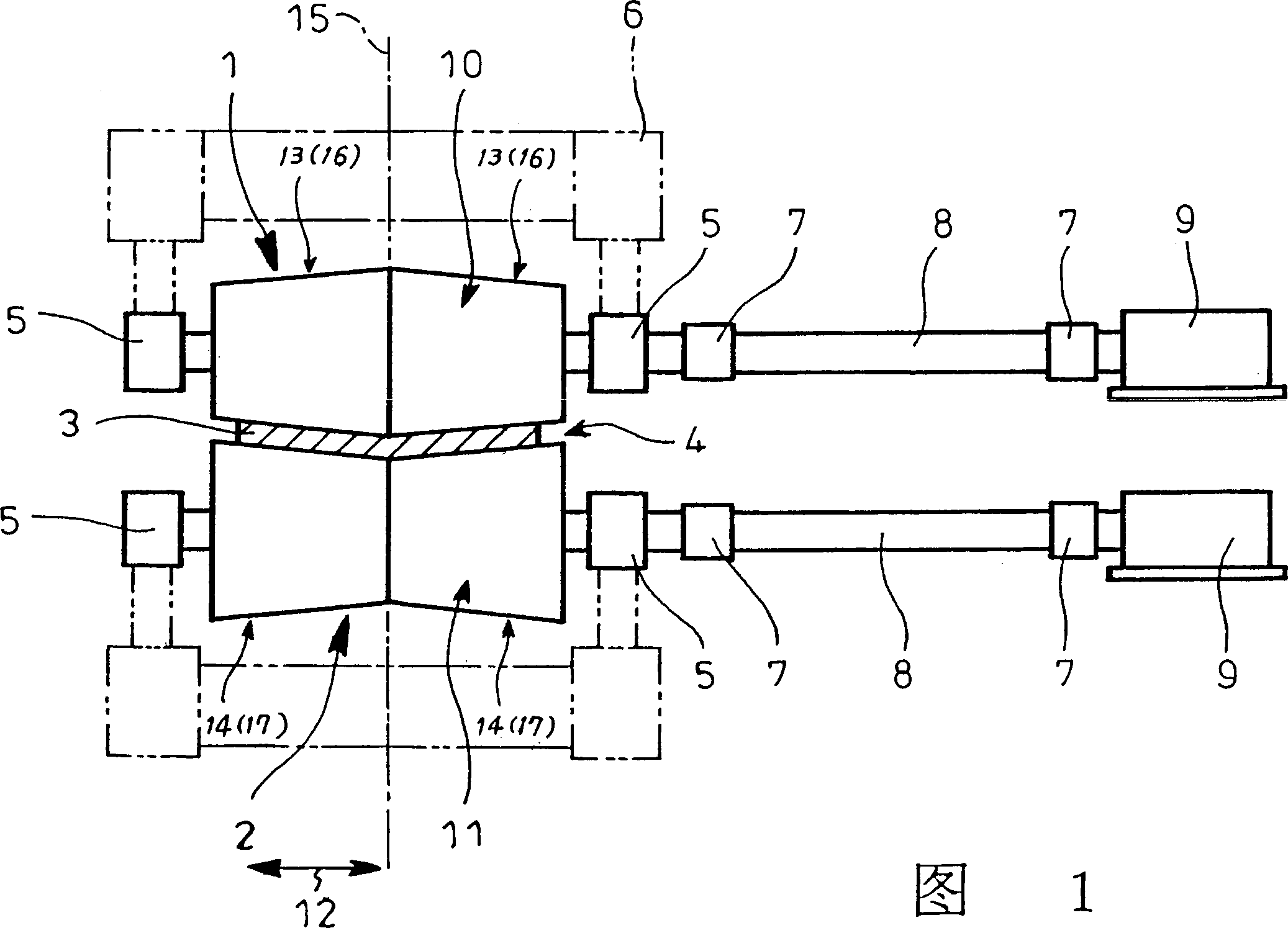

[0066] 1-6 show a first embodiment of the transverse differential rolling mill of the present invention. As shown in FIG. 1, a pair of upper roll 1 and lower roll 2 for rolling a workpiece 3 are rotatably supported by roll chocks 5 in a stand 6 at their roll ends. The rollers 1 and 2 are connected at one end (the right end of FIG. 1 ) to an independent rotary drive mechanism 9 through a universal joint 7 and a drive shaft 8, so that the speed ratio of the rollers 1 and 2 can be changed as required.

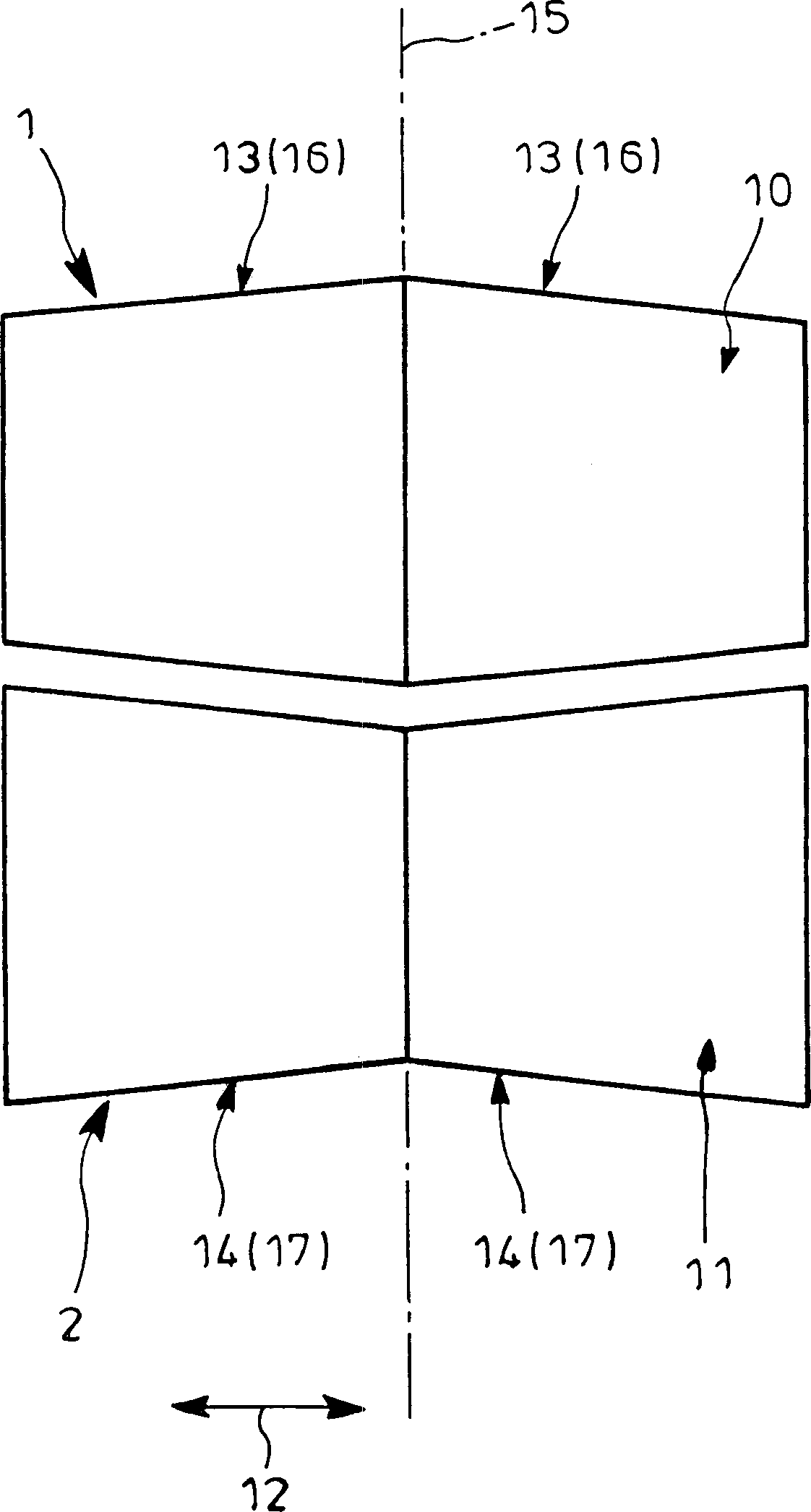

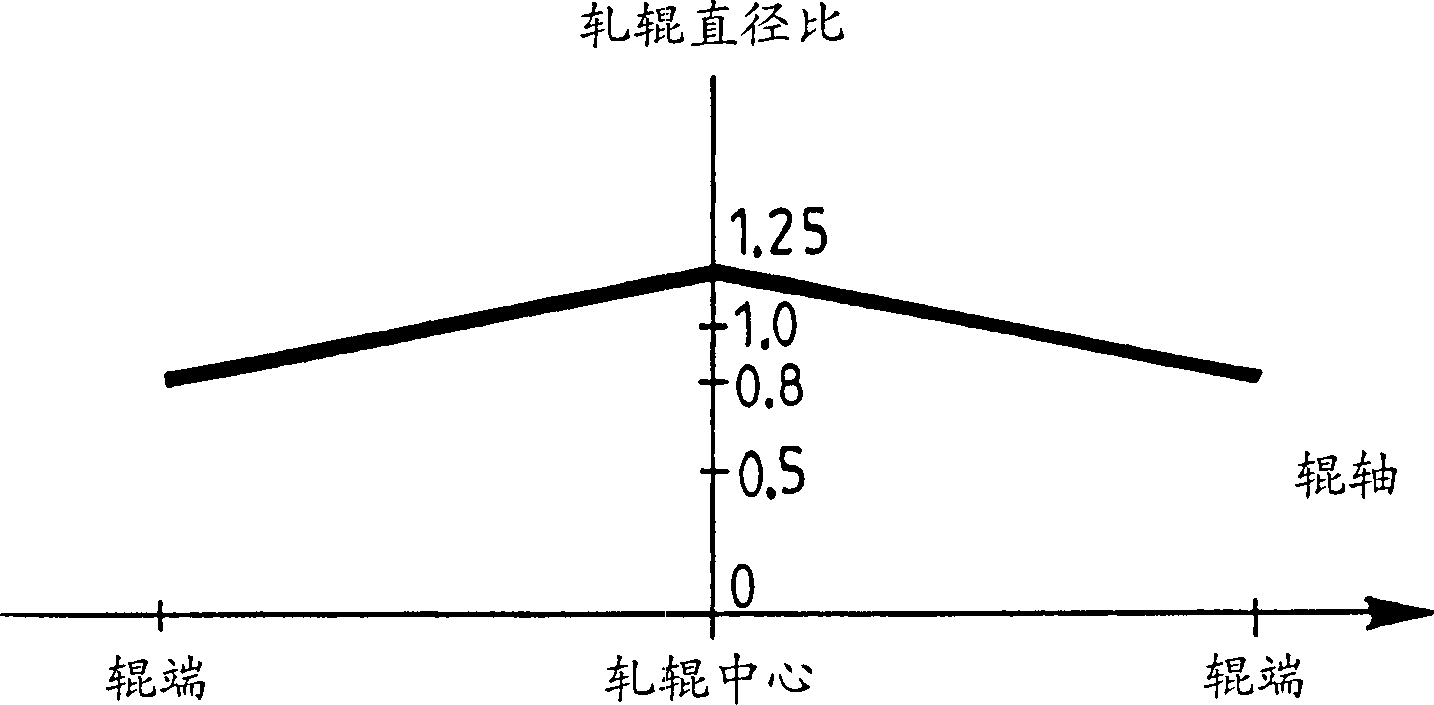

[0067] Such as figure 2 As shown in enlargement, the roll bodies 10, 11 of the rolls 1, 2 respectively include roll segments 13, 14 with different diameters and shape changes along the roll axis 12, so that the roll diameters of the roll segments 13, 14 of the roll bodies 10, 11 and are substantially constant and each roller 1, 2 is left-right symmetrical. Specifically, in this embodiment, the roll body 10 includes an outwardly converging roll section 16 that has a maximum diam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com