Preparation method for double-metal compound wire

A composite wire and bimetal technology, applied in metal rolling and other directions, can solve the problems of uneven outer wall thickness, poor welding, radial opening, etc., to improve product quality, simple production equipment, and fast deformation speed Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

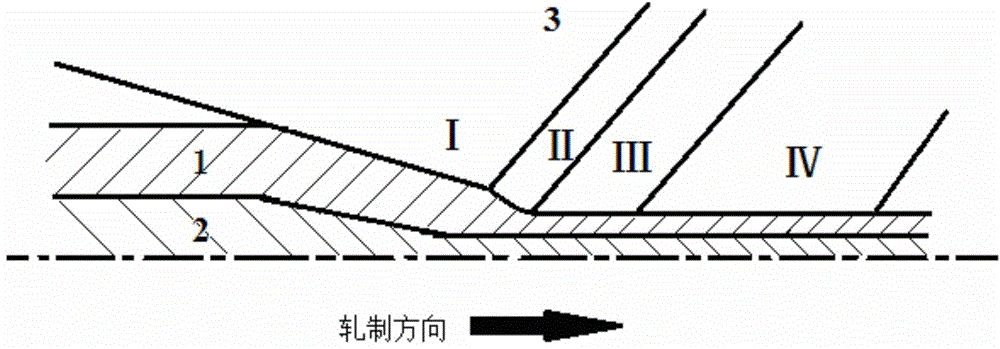

[0038] The preparation method of the bimetallic composite wire rod of the present invention, at first put together two metal pipes and rods with different materials after surface treatment, and then, as figure 1 As shown, the three-roll planetary rolling mill is used to roll the pipe 1 and the bar 2 that are nested together, pass through the roll 3, pass through the diameter reducing section I, the concentrated deformation section II, the finishing section III and the rounding section IV, so that The pipe material 1 and the bar material 2 are combined together to obtain a bimetallic composite billet. After rolling, the diameter of the composite billet is 12-40mm, and the length can reach more than 20m. The bimetallic composite billet rolled by the three-roll planetary rolling mill is rolled again with a multi-stand Y rolling mill or a vertical vertical roller mill, and rolled into a bimetallic composite wire rod with a diameter of about 5mm. Before the rolling mill, the on-line...

Embodiment 1

[0046] Preparation of pure titanium-clad copper bimetallic composite wire:

[0047] (1) Pre-treatment: the specification of pure titanium tube is 60mm in diameter, 5mm in wall thickness, the specification of copper rod is 49.5mm in diameter, the total gap between pipe and rod is 0.5mm, and the length is 5m. Use 4% (mass percentage) NaOH solution to The pure titanium tube and the red copper rod are degreased, the pure titanium pipe is pickled with 20% (mass percentage) HNO3+7% (mass percentage) HF solution, and the red copper rod is pickled with 12% (mass percentage) HCl solution, and then with A wire brush grinds the inner surface of the pure titanium tube and the outer surface of the copper rod to form a fresh metal matrix;

[0048] (2) Combination of the outer metal tube and the inner bar: insert the polished copper rod into the pure titanium tube;

[0049] (3) Planetary rolling and compounding: a three-roll planetary rolling mill is used to roll the combination of pure tit...

Embodiment 2

[0053] Preparation of pure titanium-clad No. 20 steel bimetallic composite wire:

[0054] (1) Pretreatment: the specification of pure titanium tube is 40mm in diameter, the wall thickness is 4mm, the specification of No. 20 steel rod is 31.2mm in diameter, the total gap between pipe and bar is 0.8mm, and the length is 6m, with 5% NaOH (mass percentage ) solution for degreasing pure titanium tubes and No. 20 steel rods, and pure titanium tubes with 20% HNO 3 (mass percentage)+7%HF (mass percentage) solution carries out pickling, No. 20 steel bars use 10% H 2 SO 4 (mass percentage) solution carries out pickling, then with steel wire brush the inner surface of pure titanium tube and the outer surface of No. 20 steel rods are polished out fresh metal matrix;

[0055] (2) Combination of outer layer metal tube and inner layer bar: Put the polished No. 20 steel rod into the pure titanium tube;

[0056] (3) Planetary rolling composite: use a three-roller planetary rolling mill to r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com