Rough rolling process and method for preparing high-strength high-ductility magnesium alloy sheet

A magnesium alloy and ductility technology, applied in the direction of metal rolling, can solve the problems of high production cost of magnesium alloy sheets, poor plasticity of magnesium alloy sheets, and poor processing performance at room temperature, etc., to achieve mass production and reduction The effect of large and reduced grain size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-6

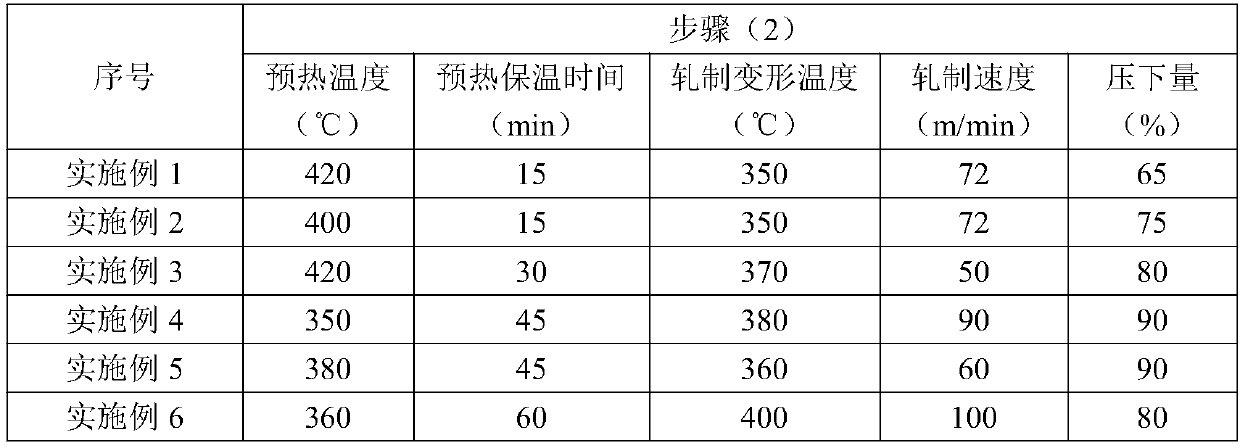

[0033] The magnesium alloy thin plate of embodiment 1-6 adopts following steps to make (concrete process parameter is listed in table 1-1, table 1-2 and table 1-3):

[0034] (1) Manufacture rolling billet: the rolling billet selects AZ31 type magnesium alloy extruded plate in the prior art, and its thickness is 10mm, and width is 400mm, and it is cut into the plate that length is 400mm before rough rolling.

[0035] (2) Rough rolling: Carry out one pass of rolling, preheat before rolling, control the preheating temperature to 300-450°C, keep warm for 15-60min, keep the rolling deformation temperature at 300-400°C, and control the rolling The production speed is 50-100m / min, and the reduction is 60-90%.

[0036] (3) Warm rolling: Preheating is carried out before each pass of warm rolling, and the preheating temperature is 180-250°C. After 1-3 passes of warm rolling to the target thickness, wherein, in a single pass of warm rolling step, the symmetrical front and rear tensions ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com