Continuous annealing process of cold rolling low alloy high-strength steel plate with yield strength at grade of 420 MPa

A technology of yield strength and annealing process, which is applied in the field of continuous annealing process, can solve the problems of high energy consumption, achieve the effects of reducing energy consumption, shortening heating, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

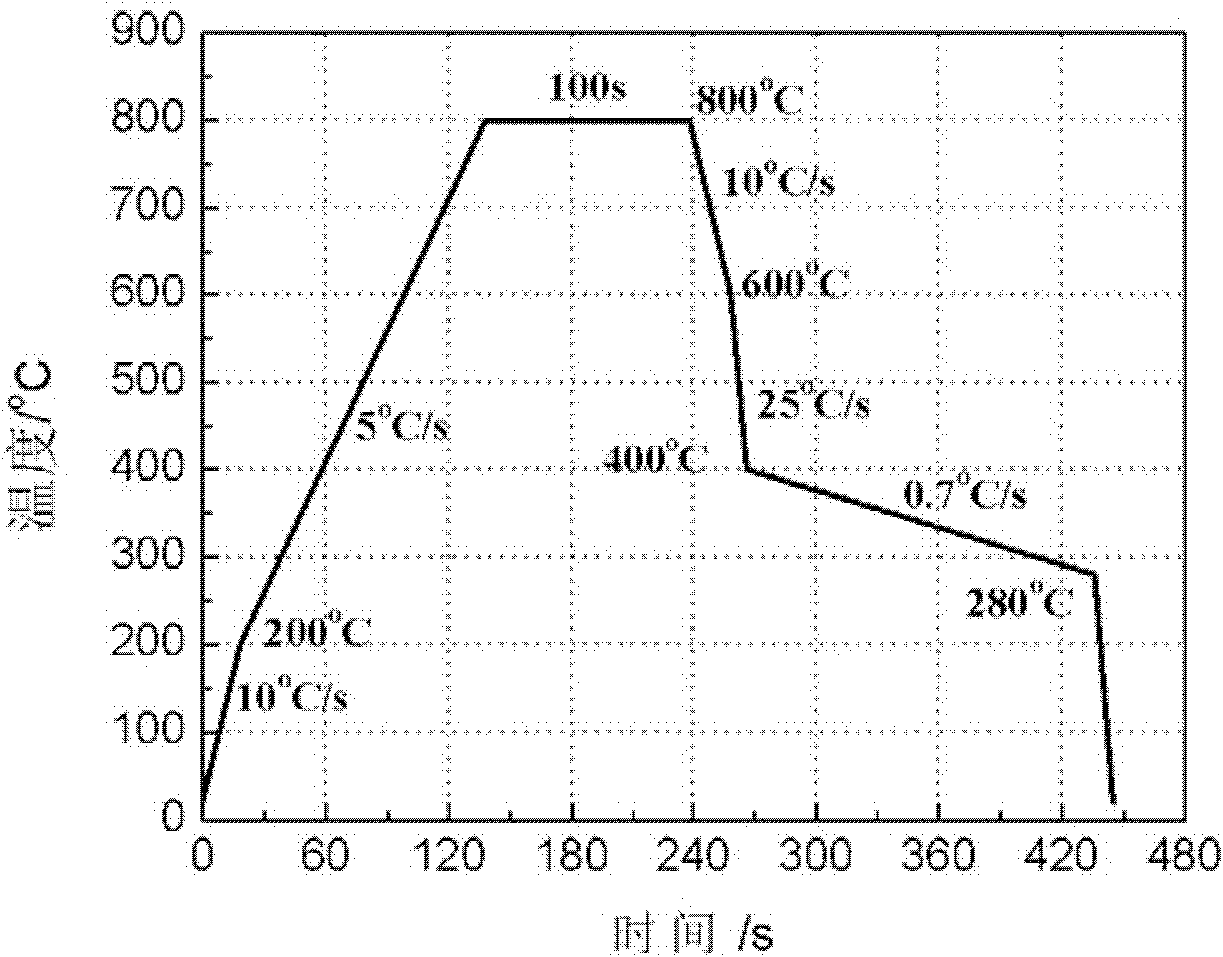

[0028] Heat the cold-rolled low-alloy high-strength steel plate of the present invention with a yield strength of 420MPa from room temperature at a rate of 15°C / s to 630°C, then at a rate of 125°C / s to 790°C, soak for 100s, and then heat at a rate of 5°C / s Cool to 620°C at a rate of 20°C / s, then cool to 290°C at a rate of 20°C / s, and finally cool to room temperature with water.

Embodiment 2

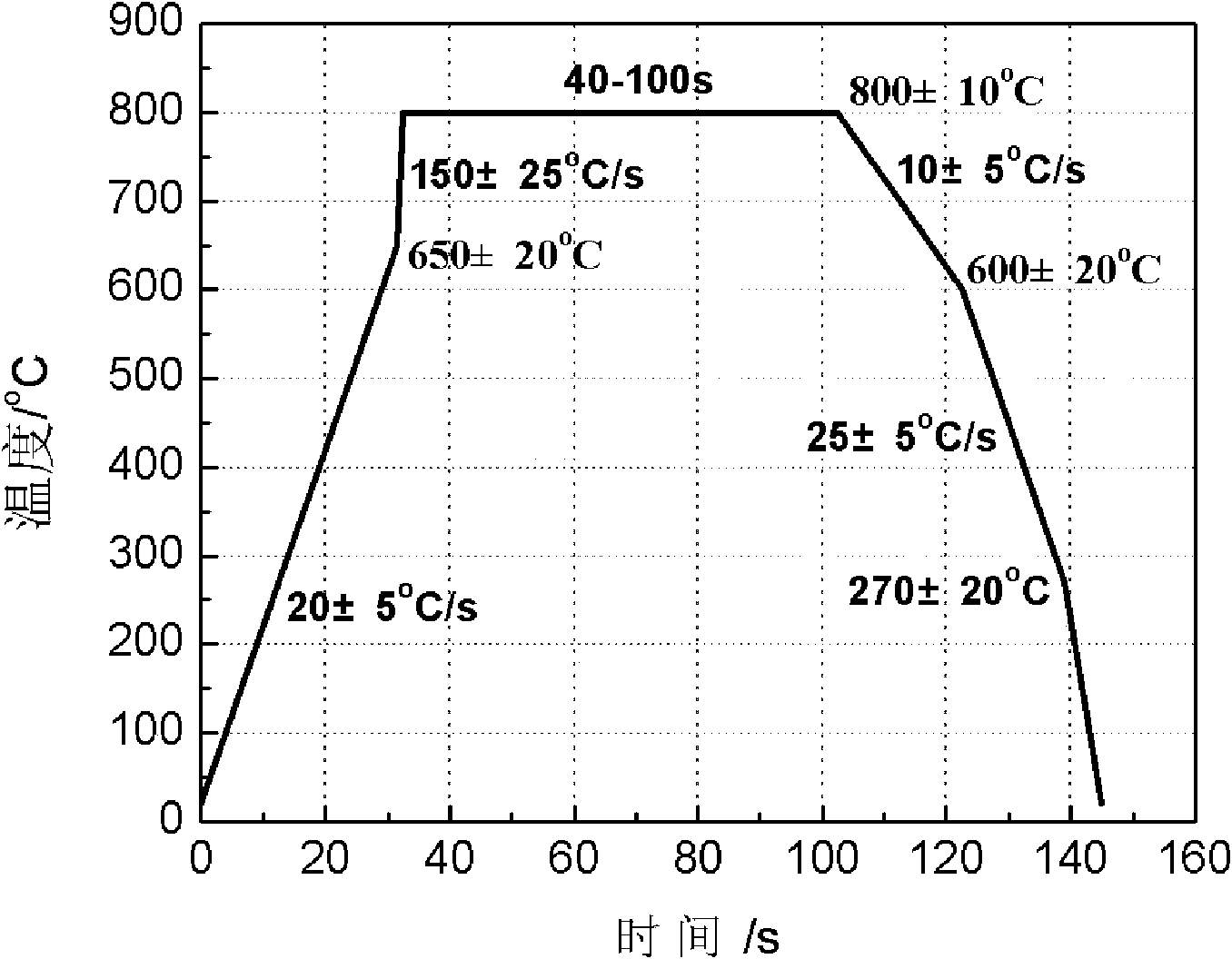

[0030] see figure 2 , heating the cold-rolled low-alloy high-strength steel plate of the present invention with a yield strength of 420 MPa from room temperature at a rate of 20 °C / s to 650 °C, then heating at a rate of 150 °C / s to 800 °C, soaking for 70 seconds, and then heating at a rate of 10 °C / s s rate to 600°C, then cooled to 270°C at a rate of 25°C / s, and finally cooled to room temperature with water.

Embodiment 3

[0032] Heat the cold-rolled low-alloy high-strength steel plate of the present invention with a yield strength of 420MPa from room temperature at a rate of 25°C / s to 670°C, then at a rate of 175°C / s to 810°C, soak for 40s, and then heat at a rate of 15°C / s Cool to 580°C at a rate of 30°C / s, then cool to 250°C at a rate of 30°C / s, and finally cool to room temperature with water.

[0033] Table 1 Experimental results of mechanical properties

[0034]

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com