Corundum-mullite low-cement self-flowing castable and method for repairing hot air outlet of top-combustion hot blast stove by using corundum-mullite low-cement self-flowing castable

A hot air outlet and castable technology, which is applied in lining repair, furnace, blast furnace, etc., can solve the problems of loose brick lining, displacement, cracking, falling off, long construction period, and high repair cost, and achieves large construction volume, high construction efficiency, and long time. The effect of service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

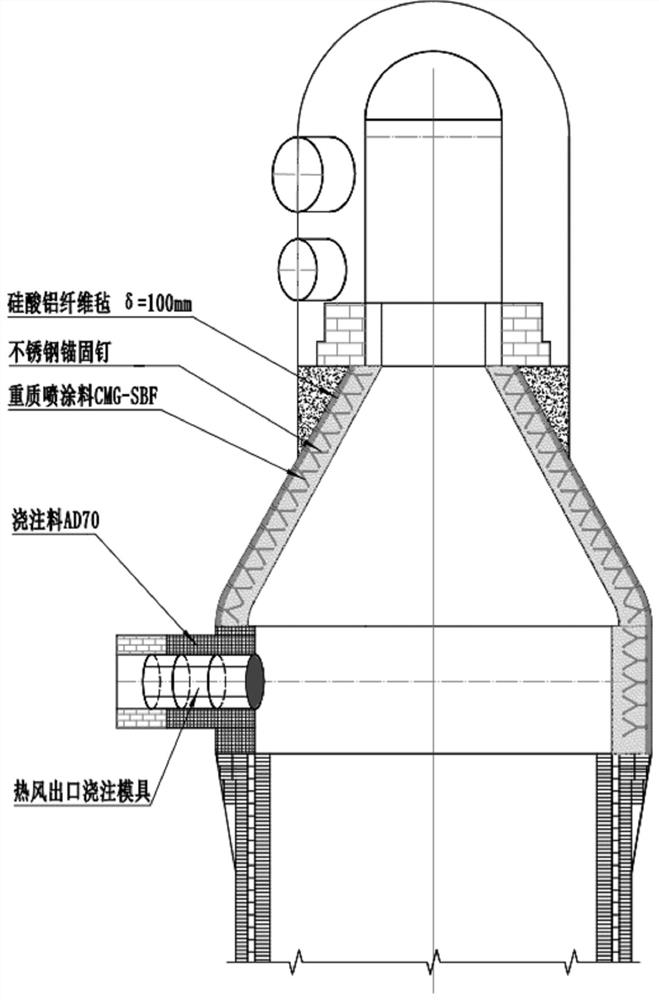

[0032] A method for repairing a hot air outlet, a cone section, and a large wall lining of a top-fired hot blast stove is carried out according to the following steps:

[0033] Open the manhole of the hot blast stove, cool the stove until people can enter the stove;

[0034] Clean the brick lining and damaged checkered bricks that have fallen off in the furnace to the outside of the furnace;

[0035] Set up shelves on the checkered brick plane to facilitate subsequent construction;

[0036] Clean the hot air outlet, cone section, collapsed large wall or loose brick lining, and clean the hot air outlet to the intact brick lining according to the actual situation of damage;

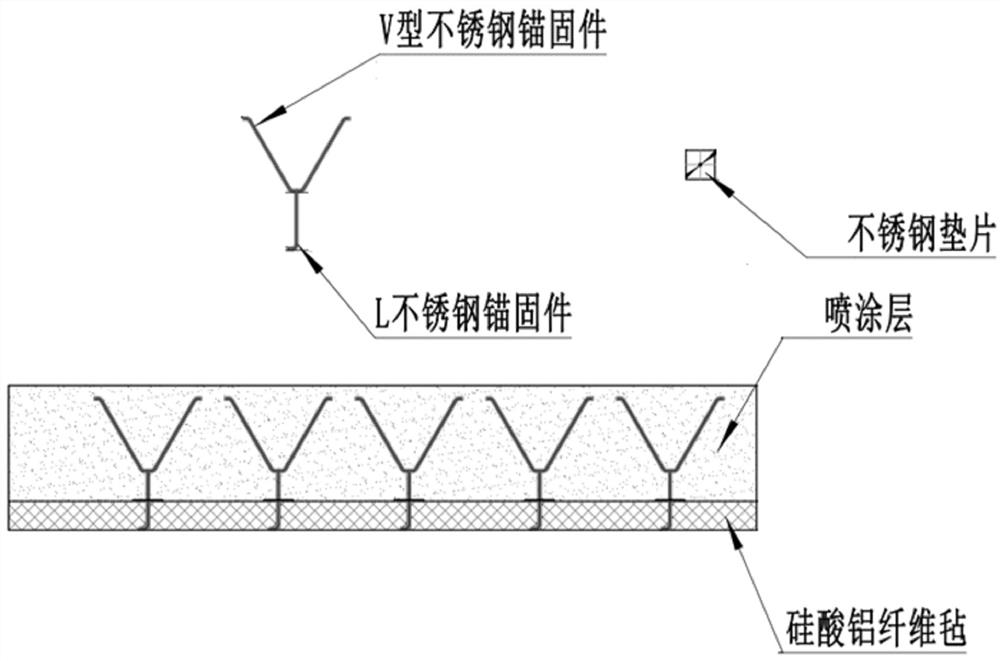

[0037] To make and weld the anchor nail system, weld L-type 304 stainless steel anchors in the cleaned furnace shell. The length of the anchors is 200mm and the welding spacing is 450mm; the L-type 304 stainless steel anchors are distributed on the surface of the entire cone section.

[0038] Press the al...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com