Production method of steel wire rod for very fine copper-clad steel wire

A copper-clad steel wire and production method technology, which is applied in the field of copper-clad steel wire wire rod production technology, can solve the problems that steel wire rod cannot meet the requirements, and the production process of ultra-fine steel wire rod for mobile phones is difficult

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

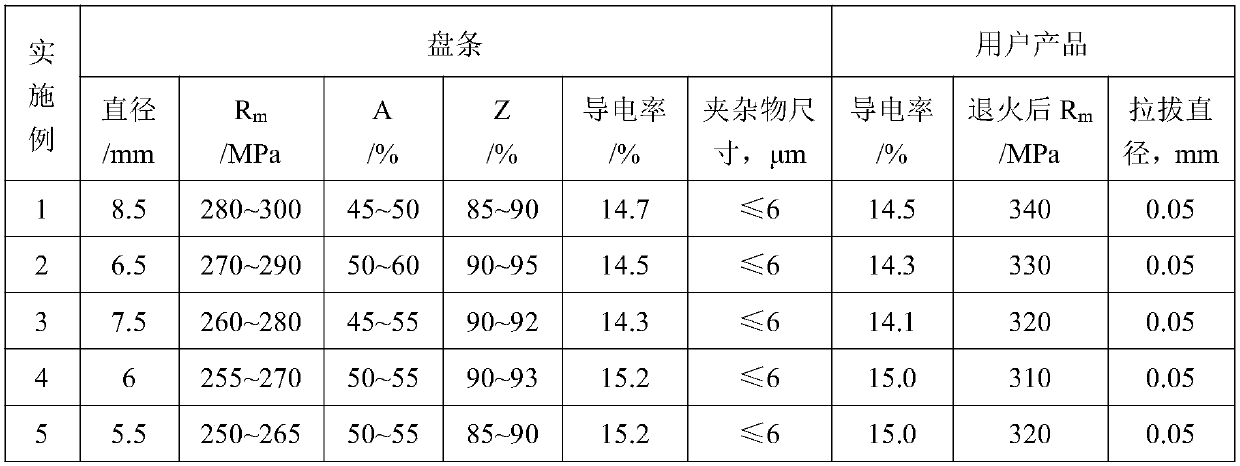

Examples

Embodiment 1

[0066] According to the above process, the specific process parameters of this embodiment are as follows: S = 0.001% of the molten iron into the furnace, converter smelting: the end carbon is 0.05%, and O is controlled at 0.040%. Tapping temperature: 1690°C; tapping without pre-deoxidation. RH refining: the cycle time after adding aluminum for final deoxidation is 12 minutes, and the finished acid-soluble aluminum is controlled at 0.010%. According to the steel composition requirements, the chemical composition of the molten steel (in the tundish) is: C 0.001%, Si 0.01%, Mn 0.25%, P 0.010%, S0.008%, N 0.005%, Als0.01%, Cu+Ni+ Cr+Mo=0.050; the steel is heated to 1200°C in the furnace, and the cross-sectional temperature difference is ≤30°C. Insulate for 180min to fully austenitize the steel. The austenitizing temperature and time are related to the composition of the steel. It is necessary to ensure that the alloying elements in the steel are completely dissolved, the furnace...

Embodiment 2

[0068] According to the above process, the specific process parameters of this embodiment are as follows: S = 0.0009% of molten iron into the furnace, converter smelting: end point carbon is 0.045%, and O is controlled at 0.045%. Tapping temperature: 1693°C; tapping without pre-deoxidation. RH refining: the cycle time after adding aluminum for final deoxidation is 13 minutes, and the finished acid-soluble aluminum is controlled at 0.009%. According to the requirements of steel composition, the chemical composition of molten steel (in the tundish) is: C 0.002%, Si 0.003%, Mn 0.20%, P 0.008%, S 0.005%, N 0.003%, Als0.01%, Cu+Ni+Cr +Mo=0.040; the steel is heated to 1200°C in the furnace, and the cross-sectional temperature difference is ≤30°C. Insulate for 160min to fully austenitize the steel. The austenitizing temperature and time are related to the composition of the steel. It is necessary to ensure that the alloying elements in the steel are completely dissolved, the furnac...

Embodiment 3

[0070] According to the above process, the specific process parameters of this embodiment are as follows: S = 0.0008% of the molten iron into the furnace, converter smelting: the end carbon is 0.040%, and O is controlled at 0.051%. Tapping temperature: 1698°C; tapping without pre-deoxidation. RH refining: the cycle time after adding aluminum for final deoxidation is 14 minutes, and the finished acid-soluble aluminum is controlled at 0.008%. According to the requirements of steel composition, the chemical composition of molten steel (in the tundish) is: C 0.003%, Si 0.006%, Mn 0.15%, P 0.007%, S 0.005%, N 0.003%, Als0.008%, Cu+Ni+Cr +Mo=0.030; the steel is heated to 1200°C in the furnace, and the cross-sectional temperature difference is ≤30°C. Insulate for 140min to fully austenitize the steel. The austenitizing temperature and time are related to the composition of the steel. It is necessary to ensure that the alloying elements in the steel are completely dissolved, the fur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com