A flux-cored electrode for stainless steel welding

A technology of stainless steel and medicine, which is applied in the direction of welding equipment, welding medium, welding/cutting medium/material, etc. It can solve the problems of uneven chemical composition of weld deposited metal, easy moisture absorption of potassium titanate, poor conductivity of welding core, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

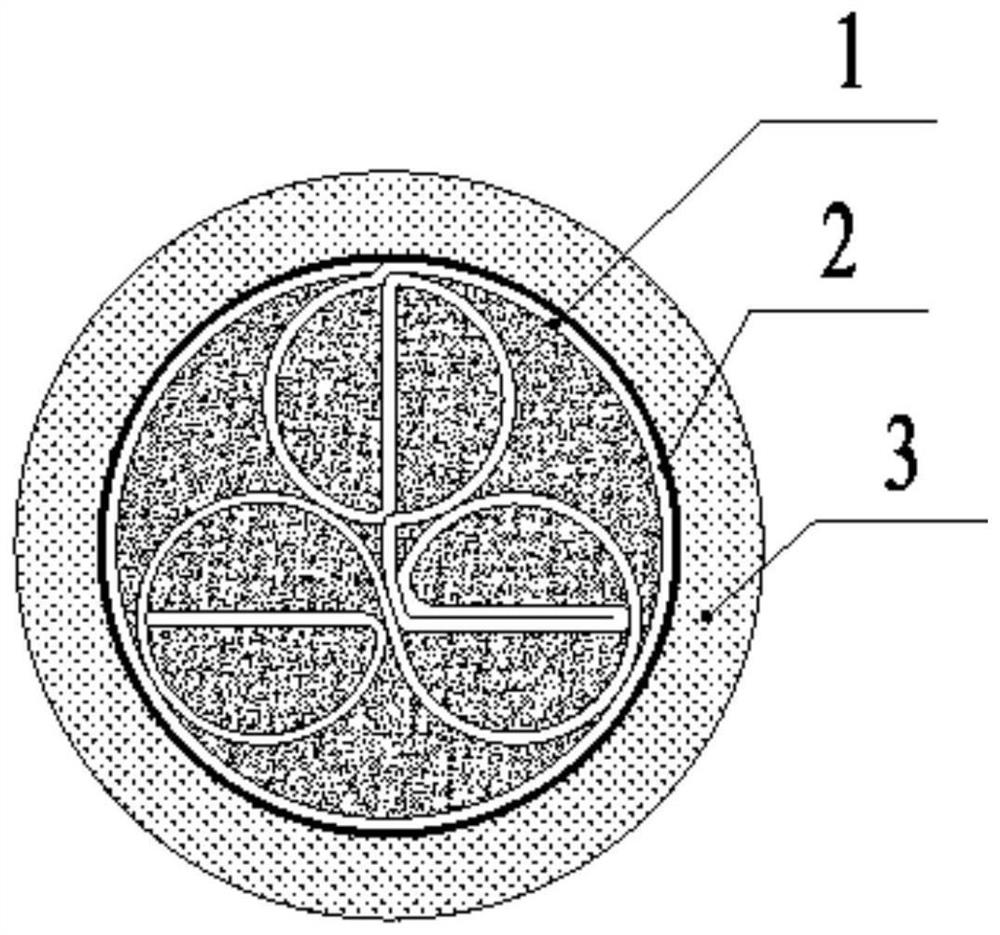

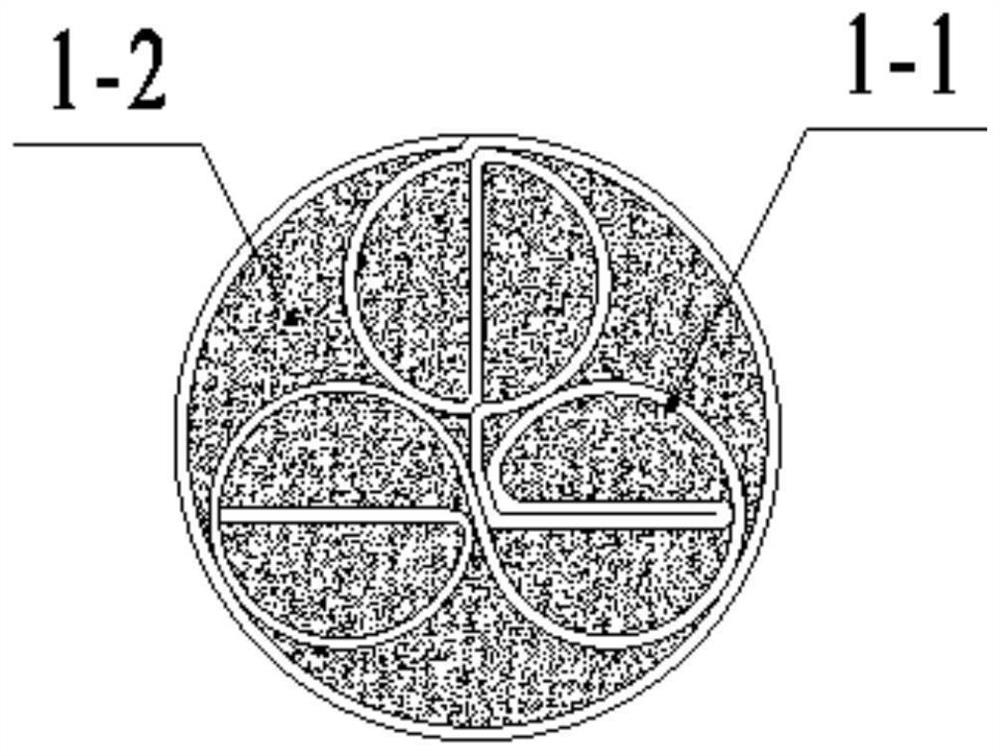

Image

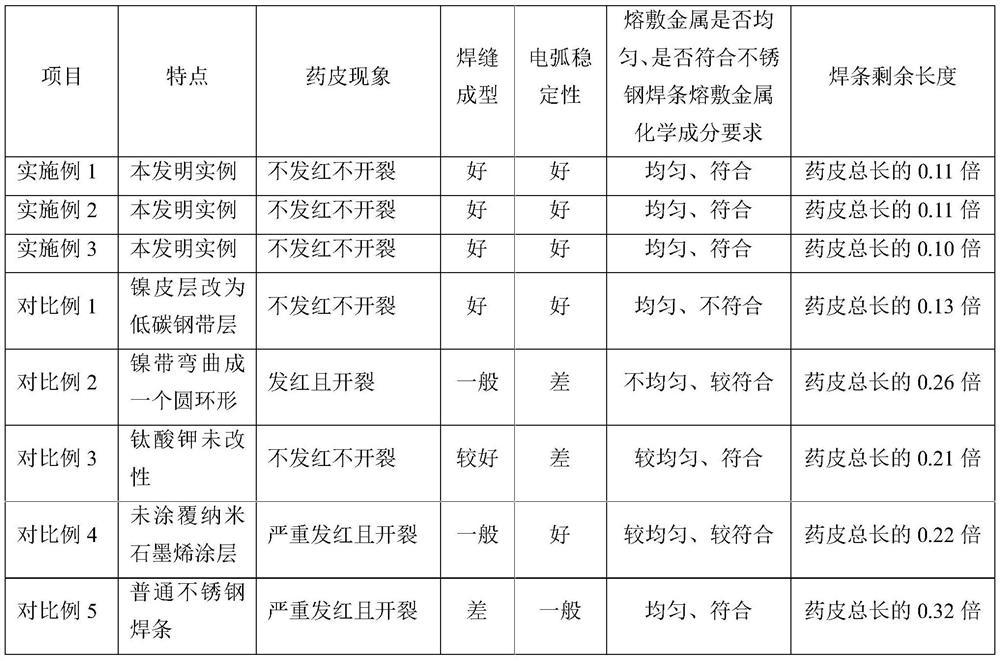

Examples

Embodiment 1

[0029] To prepare the flux-cored electrode for stainless steel welding of the present invention, the composition of the nickel belt layer is calculated by mass percentage: copper 23%, manganese 2.1%, iron 3.2%, and the remainder is nickel; the composition of the flux core is calculated by mass percentage: 32% of chromium, 2.2% of molybdenum, 2.5% of titanium, 1.2% of silicon, 3.2% of modified potassium titanate, 1.5% of cerium oxide, and the balance is iron. The composition of the modified potassium titanate is calculated by mass percentage: titanium dioxide 32%, potassium carbonate 56%, and the balance being pyrophyllite ore powder; the thickness of the nano-graphene coating is about 10nm.

Embodiment 2

[0031] To prepare the flux-cored electrode for stainless steel welding of the present invention, the composition of the nickel belt layer is calculated by mass percentage: copper 26%, manganese 2.6%, iron 3.8%, and the remainder is nickel; the composition of the flux core is calculated by mass percentage: 38% chromium, 3.0% molybdenum, 3.0% titanium, 1.8% silicon, 4.5% modified potassium titanate, 2.5% cerium oxide, and the balance is iron. The composition of the modified potassium titanate is calculated by mass percentage: titanium dioxide 34%, potassium carbonate 59%, and the balance being pyrophyllite ore powder; the thickness of the nano-graphene coating is about 20nm.

Embodiment 3

[0033] To prepare the flux-cored electrode for stainless steel welding of the present invention, the composition of the nickel belt layer is calculated by mass percentage: copper 24%, manganese 2.3%, iron 3.6%, and the remainder is nickel; the composition of the flux core is calculated by mass percentage: 35% chromium, 2.6% molybdenum, 2.7% titanium, 1.5% silicon, 3.8% modified potassium titanate, 2.0% cerium oxide, and the balance is iron. The composition of the modified potassium titanate is calculated by mass percentage: titanium dioxide 33%, potassium carbonate 58%, and the balance being pyrophyllite ore powder; the thickness of the nano-graphene coating is about 15nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com